Is Aluminum Oxide Fiber a Composite Material?

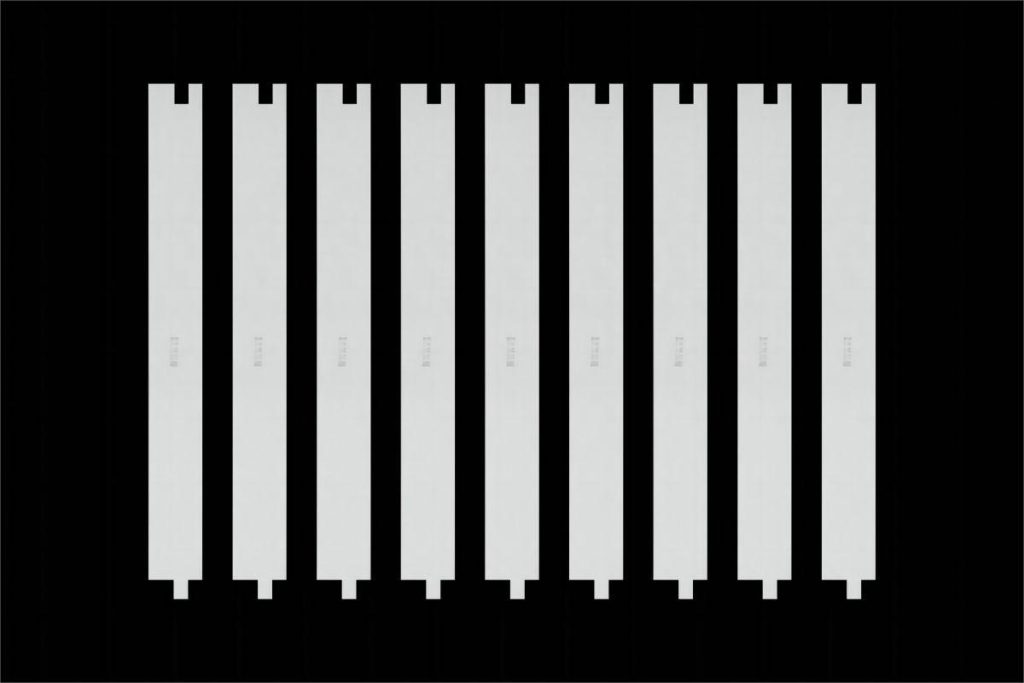

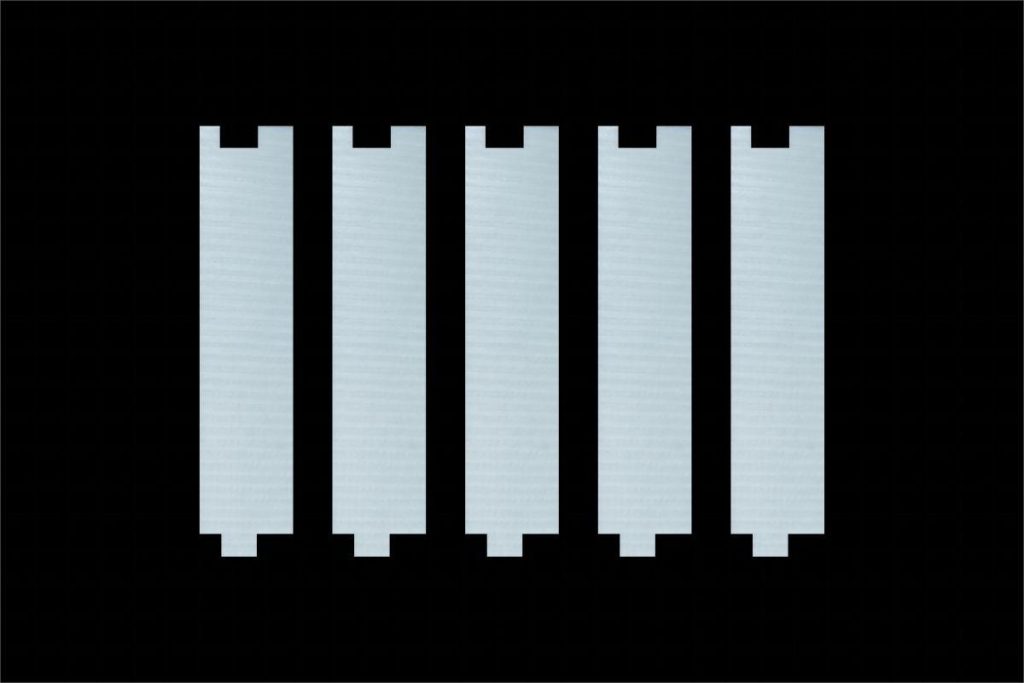

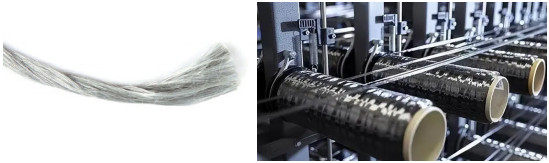

Aluminum oxide fiber, also known as polycrystalline alumina fiber, is indeed a type of composite material. It primarily consists of Al2O3 as its main component. Aluminum oxide fiber has several advantages, such as low raw material cost and simple production process. It offers a high cost-effectiveness and commercial value, leading to its widespread application in various fields. In practical use, aluminum oxide fiber is often mixed with conventional aluminum silicate fibers in different proportions to produce aluminum oxide fiber products such as sheets, felts, bricks, and prefabricated components that cater to different purposes and strength requirements.

Advantages and Applications of Aluminum Oxide Fiber

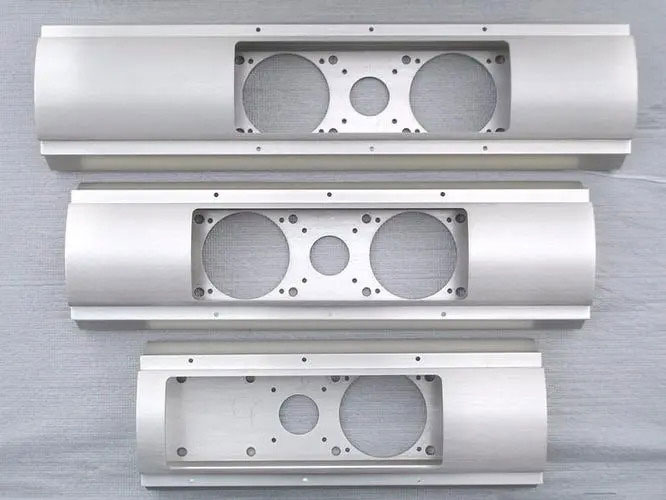

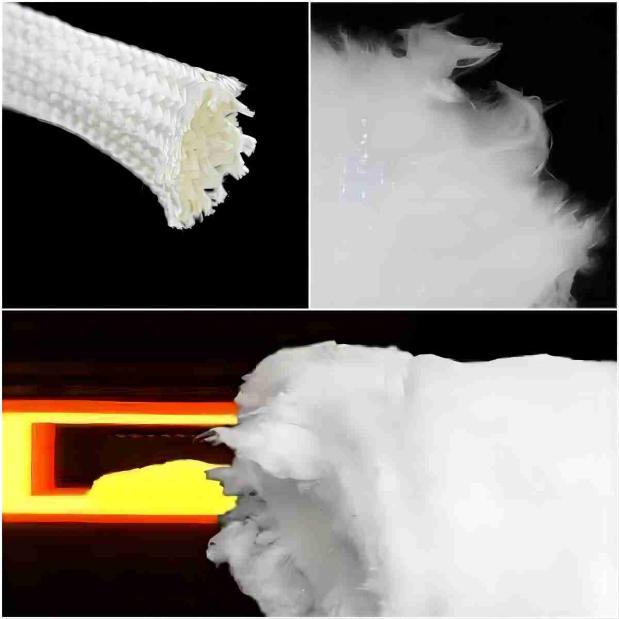

- Industrial High-Temperature Furnaces: Aluminum oxide short fibers exhibit outstanding characteristics including lightweight, high-temperature resistance, excellent thermal stability, low thermal conductivity, low heat capacity, and resistance to mechanical vibrations. Its thermal conductivity and bulk density are only about 1/10 and 1/15 of traditional refractory materials, respectively. These excellent properties make it an ideal energy-saving and efficiency-enhancing refractory material for various heat treatment furnaces in the steel industry operating at temperatures above 1,400°C, ceramic kilns, and insulation lining materials in petrochemical cracking furnaces, combustion furnaces, and more. Aluminum oxide fiber not only reduces the weight of furnace structures but also improves temperature control accuracy, reduces heat dissipation from furnace walls, and demonstrates superior insulation performance. It has less thermal storage, low thermal inertia, excellent thermal radiation capability, and infrared heating effects, resulting in significant energy savings compared to general refractory bricks or high-temperature coatings.

- Aerospace: Aluminum oxide fiber-reinforced composite materials find significant applications in the aerospace industry. For example, solid rocket motor casings for air-launched missiles made from aluminum oxide fiber-reinforced composites exhibit the same burst pressure as steel but with a 11% reduction in weight compared to aluminum alloys. Aluminum oxide long fiber-reinforced metal matrix composites are primarily used in high-load mechanical parts and high-temperature, high-speed rotating components of helicopters. They are also utilized in components requiring lightweight construction in the aerospace industry. Furthermore, aluminum oxide fiber is employed in the manufacture of solid rocket engine nozzles, simplifying the nozzle design, reducing component count by 50%, and decreasing weight by 50%. Polycrystalline refractory aluminum oxide fiber is also utilized in space missiles and nuclear energy fields as insulating materials for nuclear reactors and aerospace vehicles, as well as reinforcing materials for lightweight alloys.

- Transportation: Aluminum oxide fiber-reinforced metal matrix composites offer excellent properties such as high strength, wear resistance, heat shock resistance, and low thermal expansion coefficient. These materials have been applied in automotive piston groove components and rotating gas compressor blades, contributing to improved engine performance, enhanced engine efficiency, increased combustion rates, and reduced exhaust emissions. Aluminum oxide fiber materials can also be used as ceramic liners in automotive exhaust systems, providing structural stability.

- Novel Composite Materials: Through the use of high-strength and high-elasticity aluminum oxide fibers combined with ceramic matrix composites, excellent fiber-reinforced ceramic composites with toughness can be achieved. This significantly enhances the technological level of the ceramic industry and drives the rapid development of high-tech ceramic industries. Aluminum oxide fiber has good compatibility with resin matrices, exhibiting greater elasticity than glass fibers and higher compressive strength than carbon fibers. As a result, aluminum oxide resin composites are gradually replacing glass fibers and carbon fibers in various fields. Particularly, in sports and leisure products, aluminum oxide fiber composites can be used to manufacture brightly colored, high-strength fishing rods, golf clubs, ski boards, tennis rackets, and more.

In summary, aluminum oxide fiber, as a composite material, finds wide-ranging applications in industrial high-temperature furnaces, aerospace, transportation, and the development of novel composites. Its advantages include lightweight, high-temperature resistance, low thermal conductivity, and high strength, among others. These properties enable it to meet the diverse material performance requirements across different fields. With further technological advancements, the future of aluminum oxide fiber holds even greater potential for various industries. IF you want to learn more about alumina fiber, contact us now, and we will provide you professional service.