In the realm of advanced materials, alumina continuous fiber stands as a remarkable contender due to its exceptional properties and versatility. However, understanding how it compares to other fibers is crucial for assessing its suitability in various applications. This article delves into a comparative analysis of alumina continuous fiber and other fibers, shedding light on their properties, strengths, weaknesses, and application domains.

Alumina Continuous Fiber: A Marvel of Material Engineering

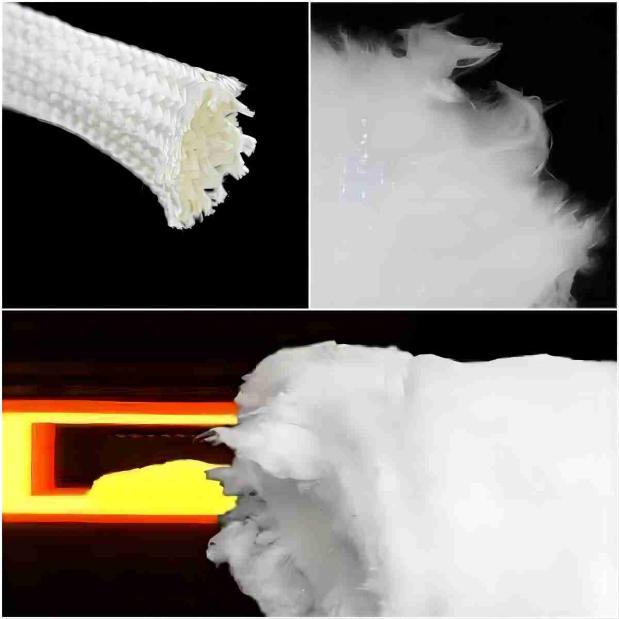

Alumina continuous fiber boasts an array of impressive properties that make it highly desirable in engineering and scientific fields. It exhibits remarkable mechanical strength, offering excellent resistance to tensile forces, bending, and impact. Its high-temperature resistance allows it to withstand extreme heat conditions, making it ideal for applications in aerospace, defense, and energy sectors. Furthermore, alumina continuous fiber demonstrates exceptional thermal conductivity and chemical stability, ensuring its longevity even in harsh environments.

Comparison Fibers: Carbon Fiber and Glass Fiber

To gain a comprehensive understanding of alumina continuous fiber, let us compare it with two prominent contenders in the fiber arena: carbon fiber and glass fiber.

Carbon fiber is renowned for its exceptional strength-to-weight ratio, making it a preferred choice in high-performance applications. It offers superior stiffness and flexibility, enabling the construction of lightweight yet robust structures. Carbon fiber finds extensive use in aerospace, automotive, and sports industries. However, its limited resistance to high temperatures and certain chemicals can restrict its applicability in extreme conditions, where alumina continuous fiber excels.

On the other hand, glass fiber exhibits excellent corrosion resistance and electrical insulation properties. It finds widespread use in sectors like construction, electronics, and telecommunications due to its affordability and versatility. While glass fiber provides good strength and chemical resistance, it may lack the exceptional mechanical and thermal properties offered by alumina continuous fiber.

Comparison Factors: Strengths and Weaknesses

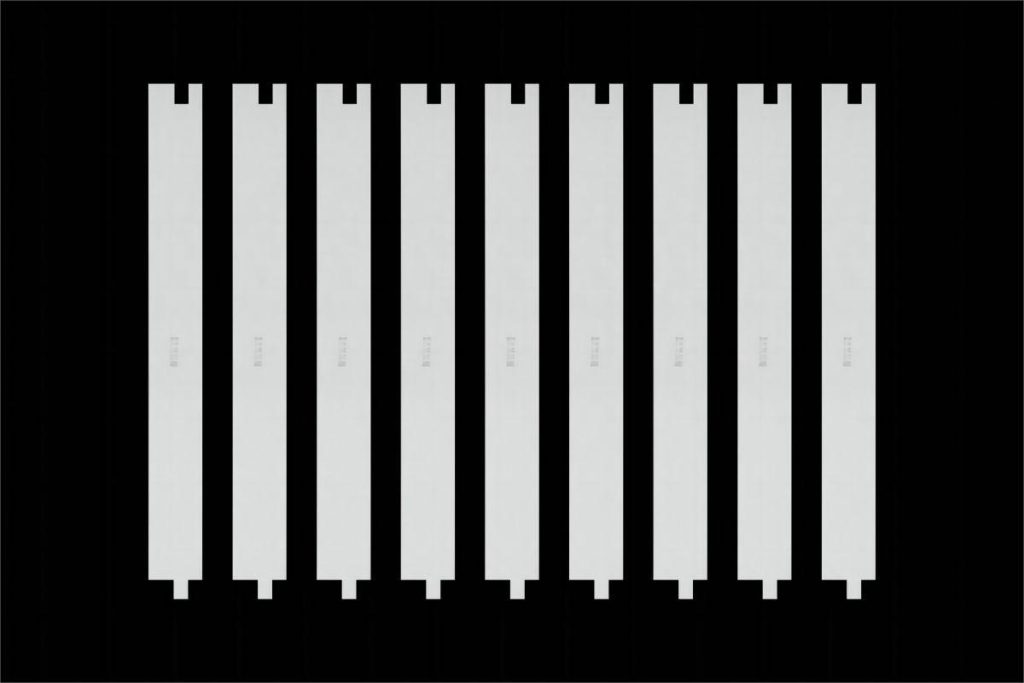

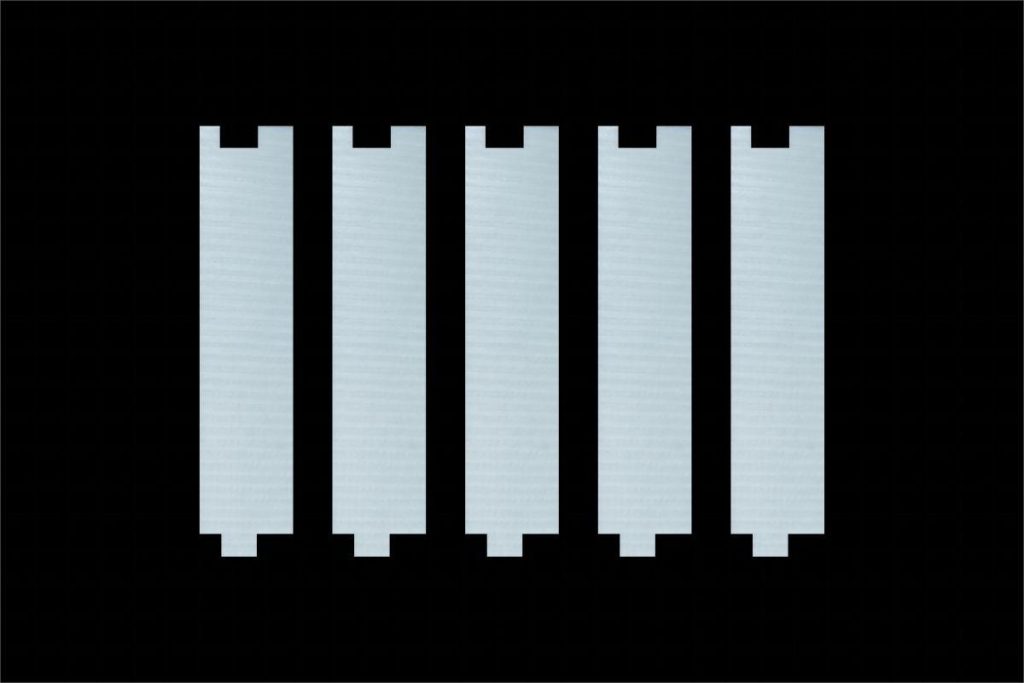

Mechanical Performance: Alumina continuous fiber boasts exceptional strength and stiffness, rivaling or even surpassing carbon fiber in some cases. Its high tensile strength and resistance to deformation make it an excellent choice for structural applications. Glass fiber, though relatively strong, may not match the mechanical prowess of alumina continuous fiber.

Thermal Performance: Alumina continuous fiber excels in high-temperature applications, exhibiting superior resistance to heat and thermal conductivity. In comparison, carbon fiber may experience degradation or loss of structural integrity under extreme heat conditions. Glass fiber possesses moderate heat resistance but falls short of the remarkable thermal properties of alumina continuous fiber.

Electrical Performance: Alumina continuous fiber offers excellent electrical insulation and high resistivity, ensuring its effectiveness in applications where electrical conductivity is undesired. Carbon fiber, on the other hand, exhibits good electrical conductivity, making it suitable for applications requiring conductivity, such as electromagnetic shielding. Glass fiber also possesses electrical insulation properties but may not match the resistivity of alumina continuous fiber.

Chemical Resistance: Alumina continuous fiber showcases exceptional chemical stability and corrosion resistance, making it an ideal choice for harsh chemical environments. Carbon fiber demonstrates varying resistance depending on the specific chemicals involved. Glass fiber offers good resistance to most chemicals but may not withstand the corrosive effects of certain aggressive substances like strong acids or alkalis as well as alumina continuous fiber.

Applications: Harnessing the Strengths

Alumina continuous fiber finds applications in a plethora of industries, including aerospace, defense, automotive, electronics, energy, and high-temperature environments. Its remarkable mechanical strength and high-temperature resistance make it a preferred choice for structural components, engine parts, and heat shields. Additionally, its chemical resistance and electrical insulation properties render it invaluable in industries dealing with corrosive chemicals and electrical insulation requirements.

Conclusion

In the world of advanced fibers, alumina continuous fiber emerges as a formidable contender due to its remarkable properties and diverse applications. By comparing it with other fibers such as carbon fiber and glass fiber, we can recognize its unique strengths and benefits. Its exceptional mechanical performance, high-temperature resistance, chemical stability, and electrical insulation properties position it as an outstanding material for demanding applications. As advancements continue in fiber technology, alumina continuous fiber is poised to play a pivotal role in shaping the future of various industries, offering reliability and performance in extreme conditions.