Aluminum discs, those unassuming circles of metal, have a surprisingly wide range of applications that touch nearly every aspect of our lives. Their lightweight nature, excellent formability, and good conductivity make them a versatile material for industries ranging from food packaging to aerospace. Let’s delve into the diverse world of aluminum discs and explore their various uses.

Uses of Aluminum Discs in Everyday Life

The most common aluminum disc encounters likely happen in your own kitchen. Pots, pans, baking sheets, and even pizza pans often utilize aluminum discs due to their exceptional heat conductivity. This property ensures even cooking and efficient heat distribution, making them ideal for everyday culinary tasks. Food packaging also heavily relies on aluminum discs in the form of beverage cans, foil containers, and lids. Their lightweight nature reduces transportation costs and environmental impact, while their malleability allows for various shapes and sizes to suit different food items.

Moving beyond the kitchen, aluminum discs play a crucial role in the construction industry. Roofs, sidings, and flashing elements frequently incorporate aluminum discs due to their durability and weather resistance. They are lightweight compared to other materials, reducing the overall weight of structures and simplifying installation. Additionally, their reflective properties can contribute to energy efficiency by deflecting heat during hot summers.

Even our furniture might be using aluminum discs without us realizing it. Table bases, chair legs, and even decorative elements can be crafted from this versatile material. The strength-to-weight ratio of aluminum discs makes them perfect for creating sturdy yet lightweight furniture pieces. Additionally, their ability to be finished in various ways, such as through painting or anodizing, allows for diverse aesthetic possibilities.

Uses of Aluminum Discs in Technology and Industry

The technical world relies heavily on the unique properties of aluminum discs. In the realm of electronics and computer components, they are frequently used as heat sinks. Their excellent thermal conductivity helps dissipate heat efficiently, preventing overheating and ensuring the proper functioning of sensitive electronic components.

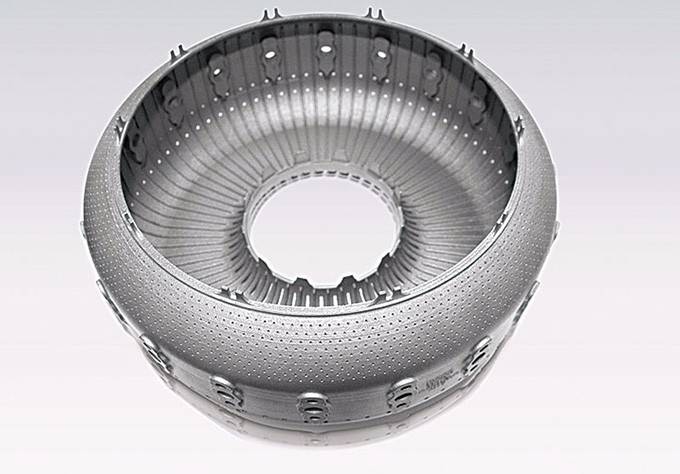

The aerospace industry also heavily utilizes aluminum discs due to their exceptional strength-to-weight ratio. Aircraft skin, fuselage components, and even wing elements can be formed from aluminum discs, contributing to the lightweight design crucial for efficient flight. This translates to increased fuel efficiency and longer flight ranges, making aluminum discs an essential material in modern aviation.

The automotive industry is another major user of aluminum discs. From body panels and wheels to engine components, their lightweight nature and malleability make them ideal for various car parts. This contributes to improved fuel efficiency and overall vehicle performance. Additionally, their corrosion resistance ensures long-lasting functionality in diverse weather conditions.

Even the electrical industry takes advantage of aluminum discs due to their good electrical conductivity and corrosion resistance. They are used in conductors, transformers, and enclosures, ensuring efficient power transmission and distribution while protecting sensitive electrical components.

Uses of Aluminum Discs in Specialized Fields

Beyond everyday and technical applications, aluminum discs find their way into specialized uses across various industries. In the medical field, dental trays and surgical instruments are often crafted from this material due to its sterilizability, lightweight nature, and corrosion resistance. This ensures patient safety and instrument longevity in demanding medical environments.

The world of sports equipment also utilizes aluminum discs. Bicycle frames, baseball bats, and even tennis rackets can be made from this versatile material. Their lightweight properties enhance athlete performance and maneuverability, contributing to a competitive edge.

The artistic realm embraces aluminum discs for their malleability and ability to take finishes well. Sculptures, mobiles, and wall art often incorporate these discs, offering unique aesthetic possibilities and reflecting light in captivating ways. Jewelry and craft enthusiasts also utilize aluminum discs for pendants, bracelets, keychains, and ornaments. Their ease of working with and affordability make them ideal for creative expression.

Uses of Aluminum Discs in Emerging Technologies

As technology advances, new and exciting applications for aluminum discs continue to emerge. The 3D printing industry is increasingly using aluminum disc filament to create lightweight, strong prototypes and parts. This opens doors for rapid prototyping and innovative product development.

The ever-growing focus on sustainability has led to the exploration of aluminum discs in solar energy applications. They are being considered for reflectors and heat exchangers due to their durability, reflective properties, and lightweight nature. This could contribute to more efficient and cost-effective solar energy systems.

Even the fight for clean water can benefit from aluminum discs. Research is exploring their use in desalination membranes due to their corrosion resistance and lightweight properties. This could lead to more sustainable and cost-effective methods of producing clean water in regions facing water scarcity.

Conclusion

Aluminum discs, often unseen and unappreciated, play a vital role in our daily lives. From the pots and pans in our kitchens to the airplanes soaring overhead, their versatility, strength, and conductivity make them an essential material across industries. As technology continues to advance, we can expect even more innovative uses for these humble metallic circles, shaping the future in ways we might not even imagine.