Exploring the Power of Heat Treatment in Enhancing Aluminum Alloys Performance

Aluminum alloys are widely used in various applications, thanks to their desirable properties such as high strength-to-weight ratio, good corrosion resistance, ease of processing, and low cost. To achieve the desired…

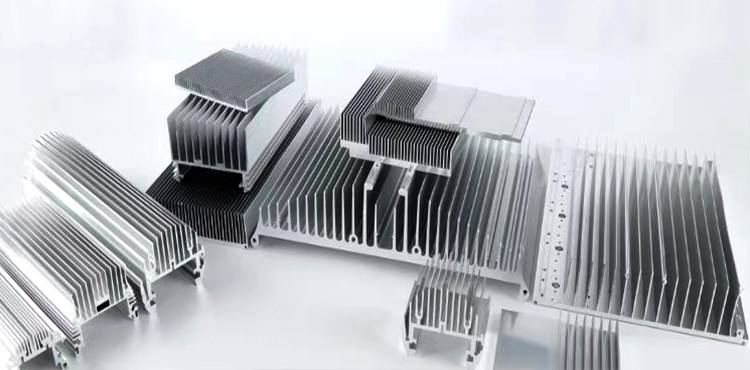

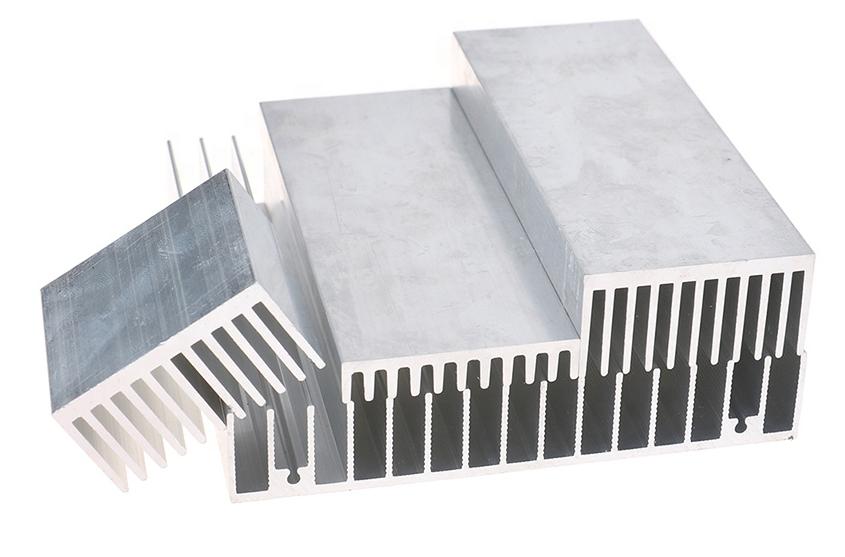

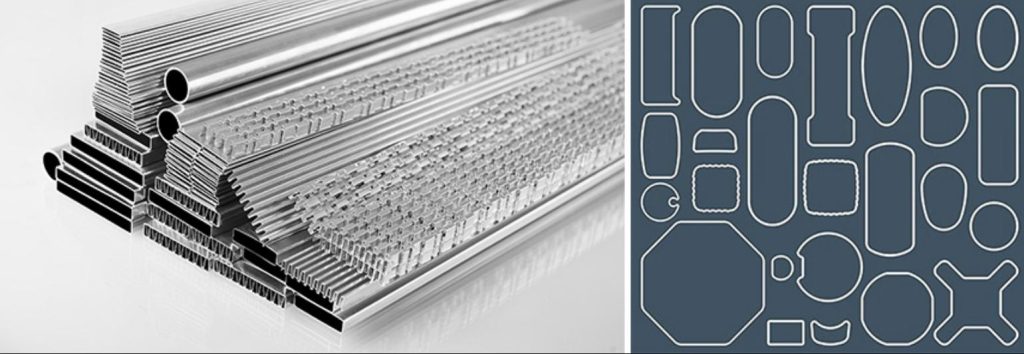

Efficient and Effective Aluminum Extrusion Processing Methods

Aluminum extrusion has revolutionized various industries with its versatility, lightweight properties, and excellent strength. To achieve high-quality aluminum profiles, it is essential to follow proper processing methods and adhere to strict…

Aluminum Foil in Air Fryer – Uses and Precautions

Air fryers have gained significant popularity in recent years as versatile kitchen appliance that allows for healthier cooking methods. These countertop devices use hot air circulation to cook food, resulting…

4 Common Surface Treatment Techniques for Aluminum Stamping Parts

Aluminum stamping parts are highly sought after by various industries due to their lightweight nature, which offers cost savings without compromising structural integrity. However, the surface of aluminum stamping parts…

Bare Aluminum Wire vs Bare Copper Wire – 4 Aspects of Comparative Analysis

In the realm of electrical wiring, two commonly used materials are bare aluminum wire and bare copper wire. Both play crucial roles in various applications, but it is important to understand…

The Specific Heat Capacity of Aluminium – Influencing Factors and Applications

Aluminum, with its exceptional properties, has become one of the most widely used metals in various industries. Its versatility, lightweight nature, and excellent thermal conductivity make it an ideal material…

Advantages of Aluminum High Frequency Welded Tube – Compared with TIG Welding and MIG Welding

Aluminum High Frequency Welded Tube (HFW Pipe) refers to a type of tubing made from aluminum alloy that is created using the high frequency welding process. It is a specialized manufacturing technique…

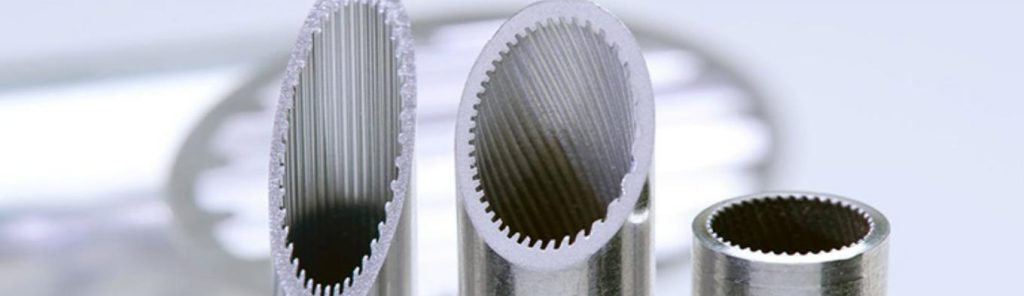

Inner Grooved Copper Tube Or Aluminum Inner Grooved Tube – How to Choose?

An inner grooved tube refers to a type of tube that features longitudinal grooves or ridges on its inner surface. These grooves are intentionally designed to increase the surface area available…

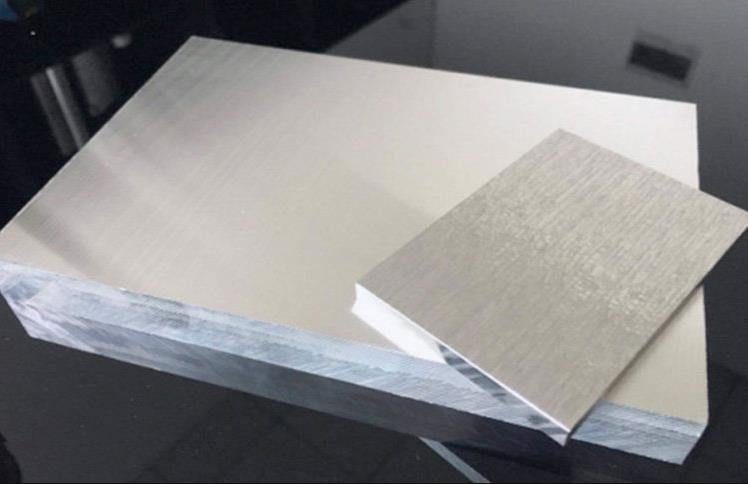

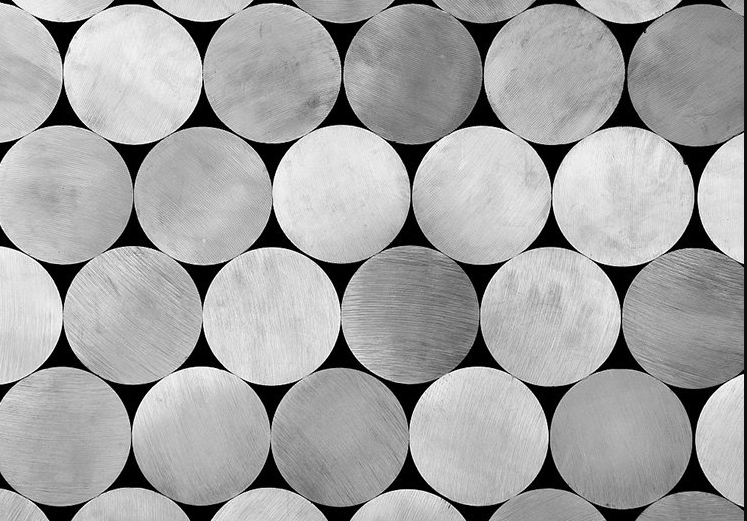

Aluminum Billet: Manufacturing Process and Common Types

Aluminum billet refers to a semi-finished product made of aluminum that is typically in a cylindrical or rectangular shape. It is produced through a process called casting or extrusion, where molten…

7 Benefits of Choosing Aluminum Swing Doors for Your Home

When it comes to selecting doors for your home, the options can be overwhelming. One versatile and practical choice to consider is an aluminum swing door. These doors offer a range…

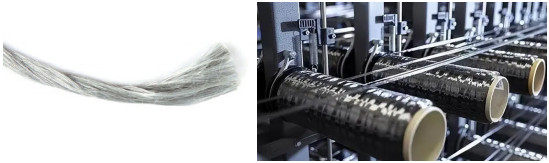

6 Differences of Carbon Fiber VS Aluminum Fiber

Carbon fiber and aluminum fiber are two distinct materials that find extensive applications in various industries. Their unique properties make them desirable choices for a wide range of products and…

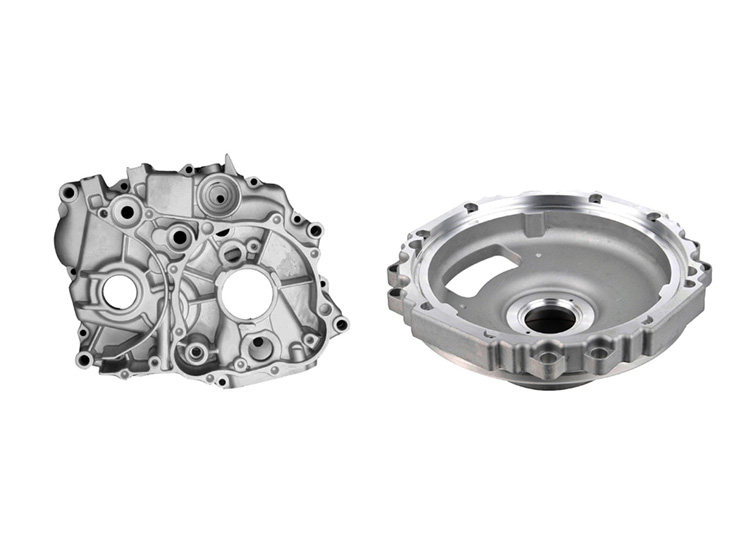

Aluminum Die Casting: Quality Control and Future Developments

Aluminum die casting is a widely used manufacturing process that offers many benefits, such as lightweight and high-strength parts. However, to ensure the production of high-quality parts, it’s important to implement…