In the fast-paced world of modern industry, efficiency, flexibility, and precision are paramount. Manufacturers and automation engineers are constantly seeking innovative solutions to meet the ever-increasing demands of production while remaining cost-effective. One such solution that has revolutionized the industrial landscape is T-slot aluminum framing. This versatile and intelligent building material has emerged as the smart choice for industry, offering a wide range of benefits and finding specific applications in manufacturing and automation processes.

Understanding T-Slot Aluminum Framing

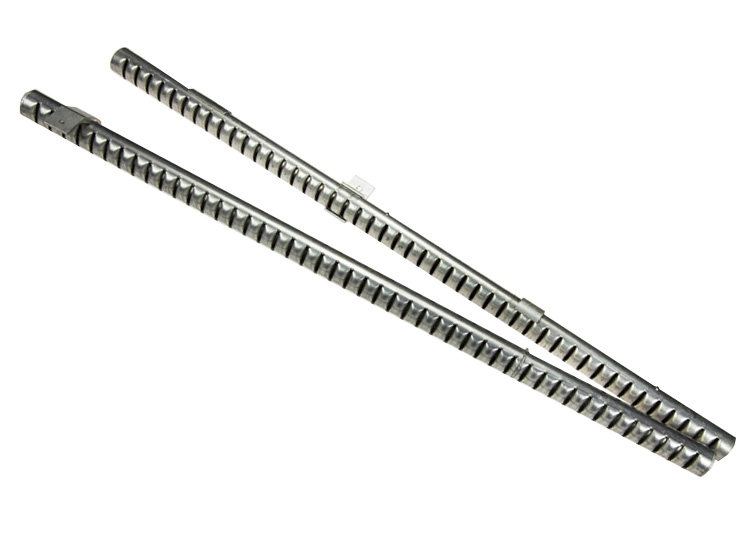

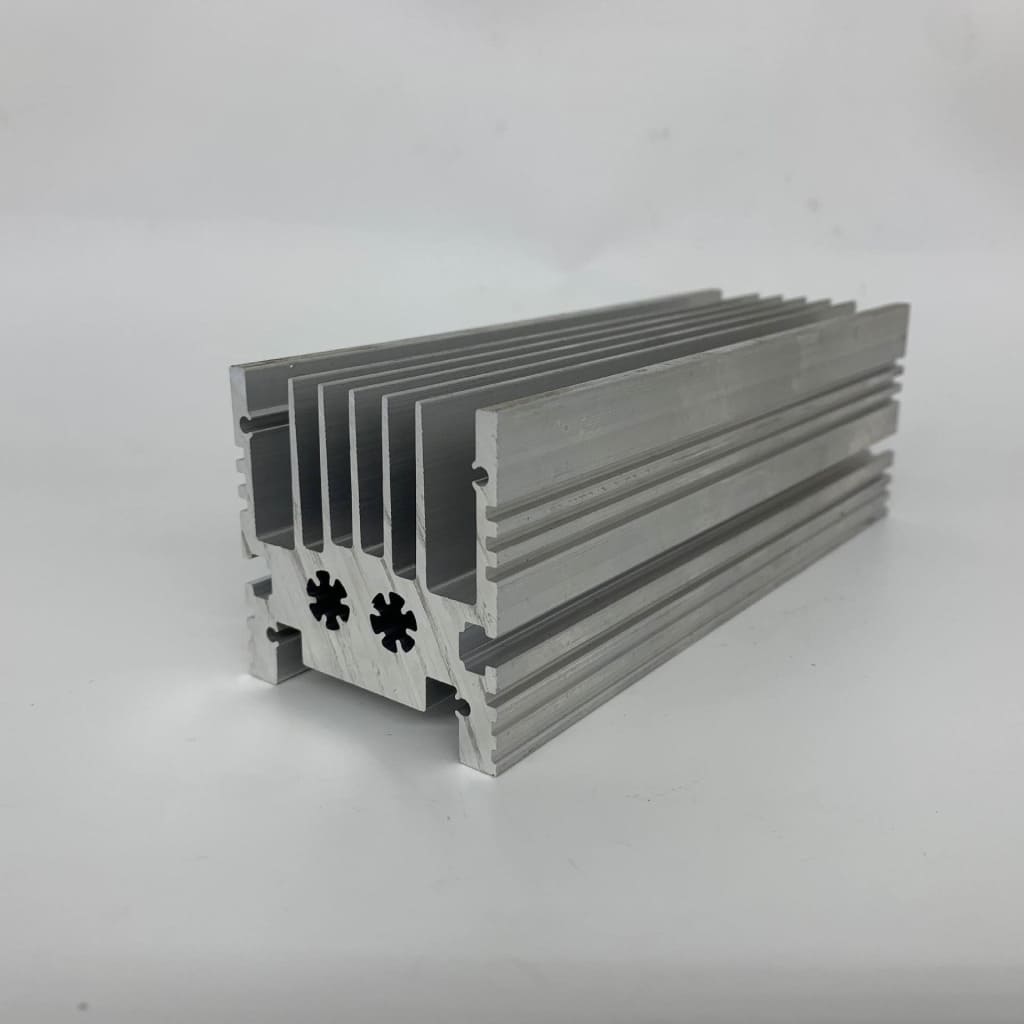

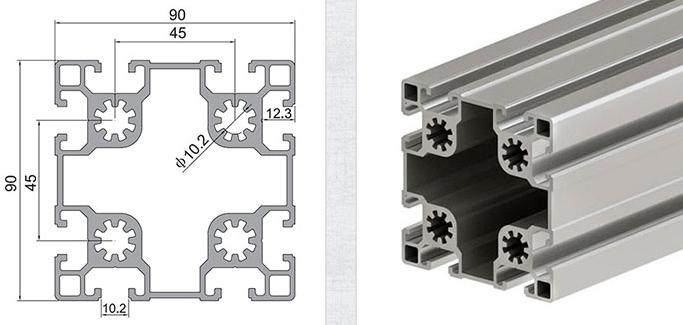

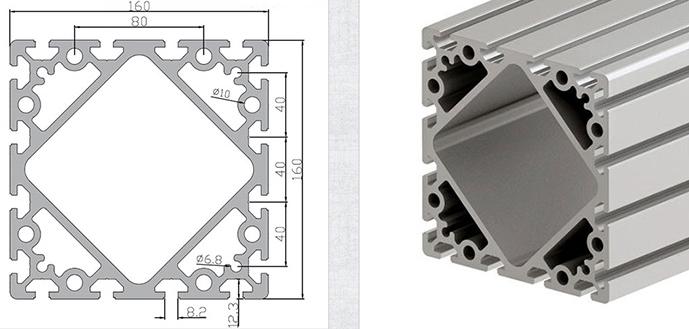

- slot aluminum framing is a modular construction system that utilizes extruded aluminum profiles with T-shaped slots along their length. These T-slots allow for easy insertion and fastening of various components such as connectors, brackets, fasteners, and accessories. The unique design of T-slot aluminum profiles makes them an ideal solution for constructing robust and adaptable structures, frames, and assemblies in a variety of industrial settings.

The Advantages of T-Slot Aluminum Framing

- Versatility: T-slot aluminum framing offers unparalleled versatility, allowing engineers and designers to create custom structures and workstations to suit their specific needs. Its modular nature enables quick and easy adjustments or expansions, making it an excellent choice for projects that require frequent reconfiguration.

- Strength and Durability: Despite its lightweight, aluminum is remarkably strong and durable. T-slot aluminum framing can withstand heavy loads, vibration, and harsh environments, ensuring long-lasting and reliable performance in demanding industrial applications.

- Easy Assembly: The straightforward design of T-slot aluminum profiles simplifies the assembly process. Standard connectors and fasteners enable rapid construction, reducing downtime and increasing productivity.

- Cost-Effectiveness: T-slot aluminum framing’s reusability and flexibility translate to cost savings. Components can be disassembled and reassembled for different projects, reducing the need for new materials.

- Ergonomics and Safety: T-slot aluminum framing allows for the creation of ergonomic workstations and safety barriers, enhancing the well-being of workers and minimizing the risk of accidents.

- Customization and Innovation: T-slot aluminum profiles offer endless possibilities for customization and innovation. Engineers can integrate linear motion components, electrical accessories, and other specialized equipment to optimize manufacturing and automation processes.

Specific Applications in Manufacturing

T-slot aluminum framing finds numerous specific applications in the manufacturing industry, revolutionizing how products are made and assembled.

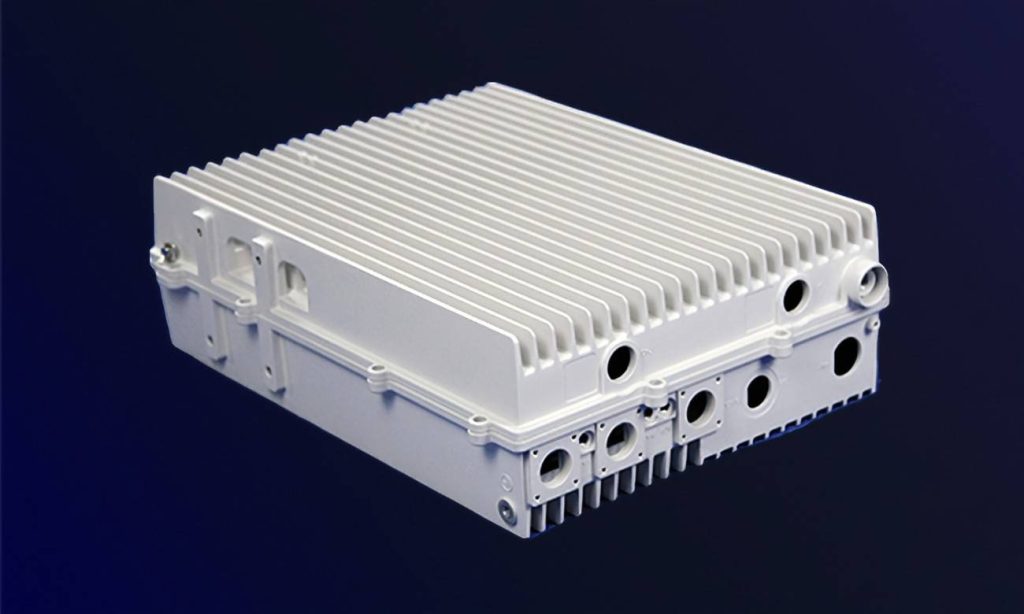

- Machine Frames and Bases: T-slot aluminum framing serves as a reliable framework for machine frames and bases, providing stability and precise alignment for manufacturing processes.

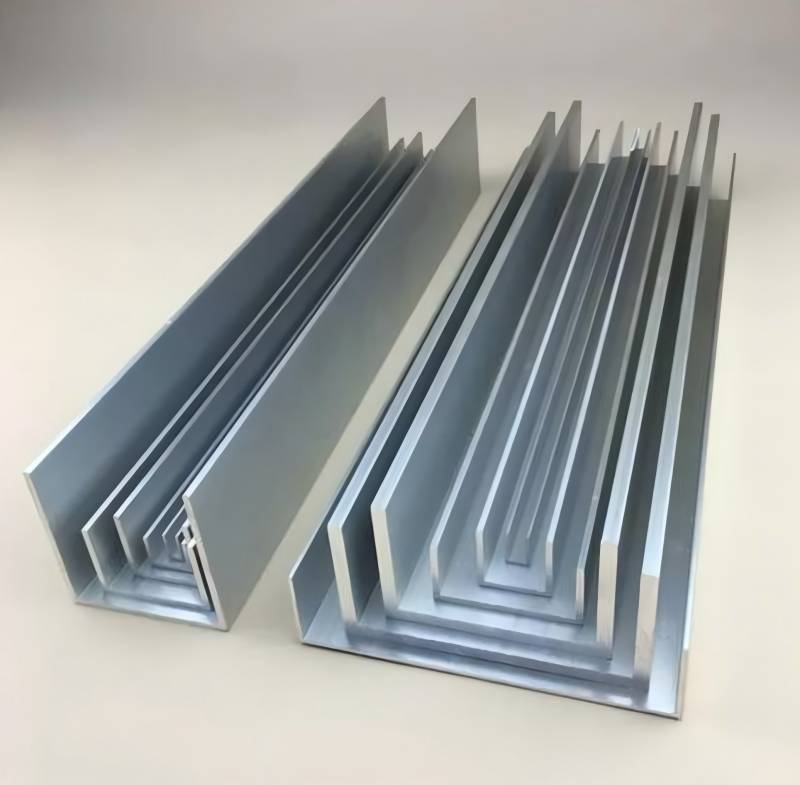

- Workstations and Assembly Lines: The flexibility of T-slot aluminum allows for ergonomic workstations and efficient assembly lines, streamlining production operations.

- Conveyor Systems: T-slot aluminum framing is ideal for constructing conveyor systems that facilitate material handling and product transportation within the manufacturing facility.

- Inspection Fixtures and Jigs: T-slot aluminum framing is used to build inspection fixtures and jigs, ensuring accurate and repeatable quality control during the manufacturing process.

- Custom Industrial Equipment: Engineers can create custom industrial equipment and machinery using T-slot aluminum framing, tailoring solutions to specific manufacturing requirements.

Specific Applications in Automation and Robotics

T-slot aluminum framing is an indispensable asset in the realm of automation and robotics, providing the necessary infrastructure for streamlined and precise operations.

- Robotics and Automation Frameworks: T-slot aluminum framing forms the backbone of robotic and automation systems, offering a stable and adaptable platform for robotic arms and end-effectors.

- Test and Inspection Stations: T-slot aluminum structures are used to build test and inspection stations, allowing for the efficient evaluation of products and components.

- AGVs and Material Handling Robots: Automated Guided Vehicles (AGVs) and material handling robots benefit from T-slot aluminum framing due to its lightweight and durable construction.

- Cleanroom Robotics: T-slot aluminum framing is employed in constructing cleanroom environments for robots involved in manufacturing sensitive components.

- Automation Workcells: T-slot aluminum framing enables the creation of automation workcells, where multiple machines and robots collaborate to carry out intricate manufacturing tasks.

Conclusion

T-slot aluminum framing has proven to be the smart choice for the manufacturing and automation industries, providing unmatched versatility, strength, and efficiency. Its adaptability and ease of assembly make it a game-changer in optimizing production processes and revolutionizing industrial equipment design. Whether used in workstations, conveyor systems, machine frames, or automation workcells, T-slot aluminum framing continues to drive innovation, setting new standards for modern industry. As the industrial landscape continues to evolve, T-slot aluminum framing will undoubtedly remain at the forefront of intelligent and flexible solutions for years to come.