Aluminum profiles can be processed from various types of aluminum materials. According to the different types of aluminum materials, the properties of the processed aluminium profiles are also different. So how to choose the right aluminum profile for you?

What is aluminum profile?

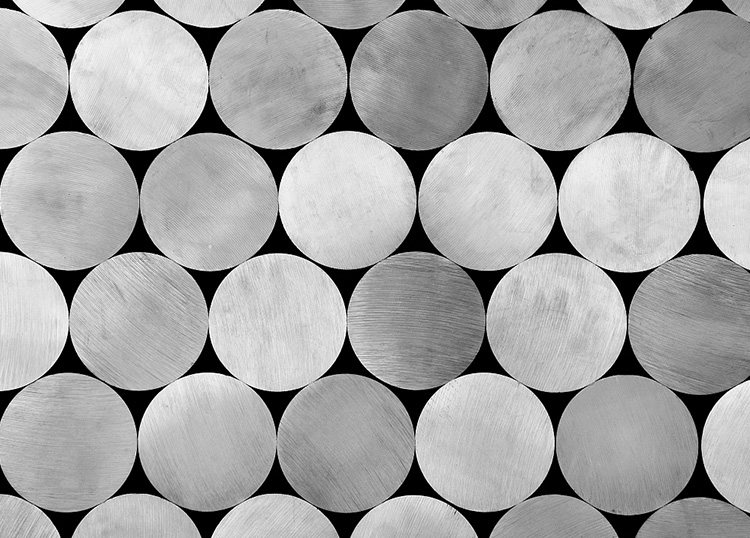

Aluminum is a silvery white gold. In humid air, aluminum can form an oxide film that prevents metal corrosion, with a relative density of 2.7g/cm3, a melting point of 660°C, a boiling point of 2327°C, high specific strength, good electrical and thermal conductivity, high reflectivity and Oxidation resistance.

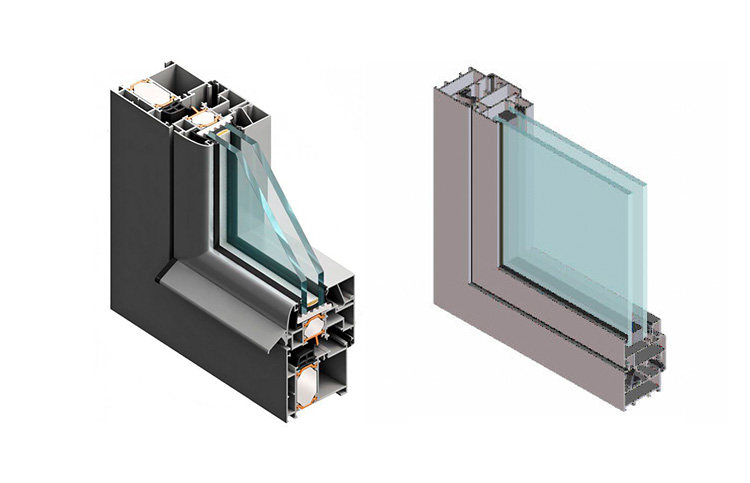

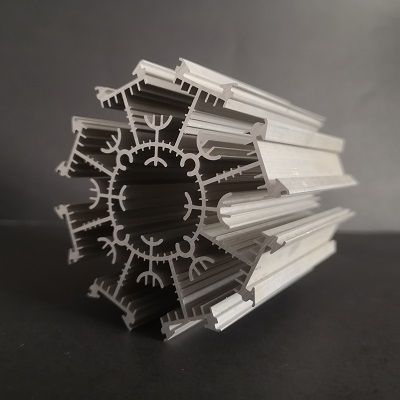

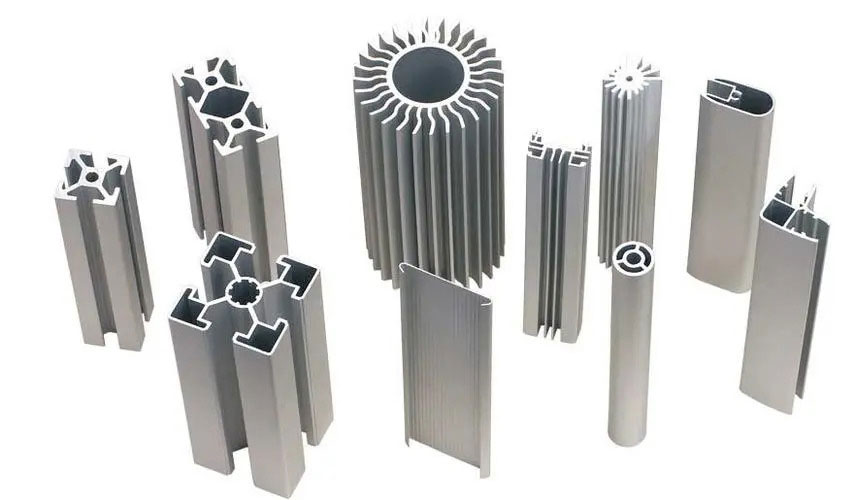

Therefore, aluminum is an excellent match for the finished material. These aluminum parts, including windows and radiator fins, are called aluminum profiles.

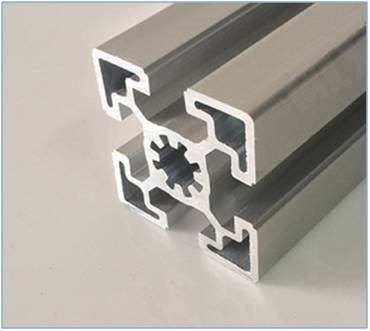

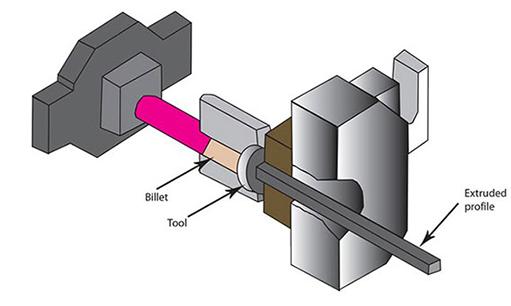

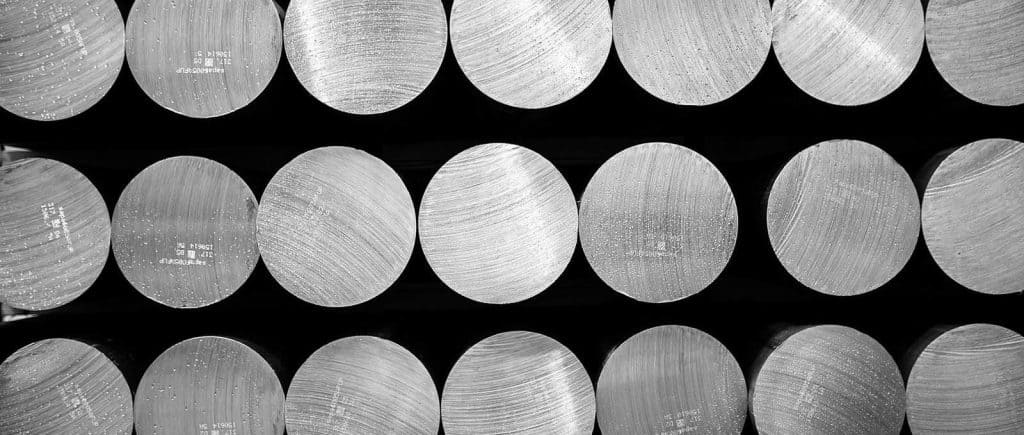

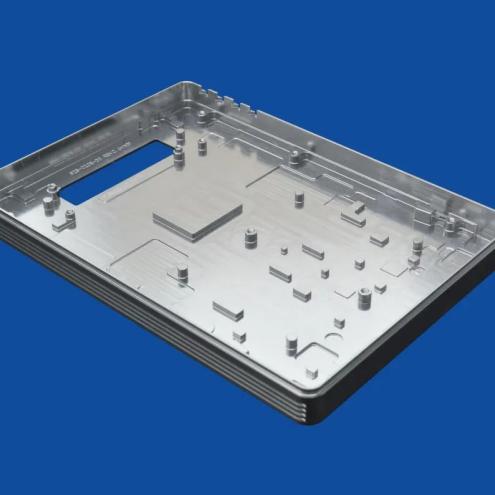

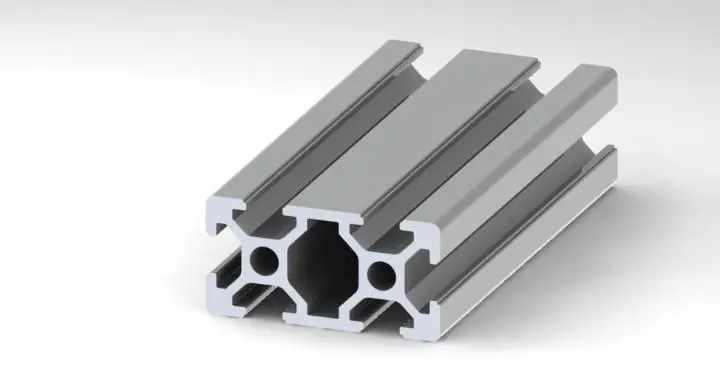

Aluminum profiles are aluminum tube materials with different cross-sectional shapes obtained by hot melting and extrusion of aluminium rods. The forming process of aluminum profiles mainly includes five processes: casting, extrusion, cutting, CNC washing and cutting, surface pretreatment, and coloring.

What are the types of aluminum profiles?

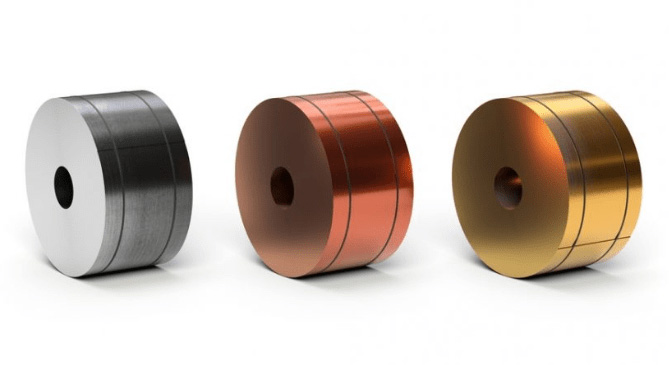

Aluminum profiles can be processed from any type of aluminum, and 1-series aluminum to 7-series aluminum can be processed as raw materials for aluminium profiles. Therefore, they also correspond to the aluminum profiles of different license plates.

We usually use “grades” to refer to different types of aluminum profile products. The first digit in the “grade” indicates the aluminium alloy series, the second digit indicates the modification of the original aluminum alloy, and the last two digits indicate the purity of the aluminum alloy in the same group.

- 1100 aluminum: It is used to manufacture corrosion-resistant aluminium profiles, which usually do not require high rigidity. Such as storage containers, sheet metal workpieces, deep-drawn concave vessels, heat exchangers, printing plates, nameplates, reflectors, etc.

- 2011 Aluminum: It is used for free-cutting alloys, with good machinability and high strength, but poor corrosion resistance. It is suitable for volume shafts, optical components, screw heads, screws, and machining products that require good cutting performance.

- 3003 aluminum: It has the properties of 1xxx series alloys and has higher strength than 1xxx series alloys, such as kitchen utensils, food, and chemical product processing and storage devices, tanks, and tanks for transporting liquid products, and various pressure vessels and sheet metal processing. pipeline.

- 4A01 Aluminum: It has high silicon content, heat resistance, and wear resistance. It is used in construction materials, machine parts, forging materials, welding materials, and other fields.

- 5052 aluminum: It is the most representative product of medium-strength alloys. It has good corrosion resistance, weldability, and formability, especially high fatigue strength and good seawater resistance. Therefore, it is used in the manufacture of aircraft fuel tanks, oil pipes, sheet metal parts for vehicles and ships, instruments, street lamp brackets and rivets, hardware products, and other products.

- 6061 Aluminum: It is a heat-treated alloy, 6061 alloy has extremely high corrosion resistance. Therefore, it is suitable for the production of screws, ships, vehicles, and other products.

- 6N01 aluminum: It is a medium-strength extrusion alloy, which can be used for large-scale thin meat profiles with complex shapes, with good corrosion resistance and weldability. Suitable for vehicles, land structures, and ships.

- 6063 aluminum: a representative alloy for extrusion, its strength is lower than that of 6061, and its extrudability is good. It can be used as a profile with complex cross-sectional shapes. It has good corrosion resistance and surface treatment. It is suitable for building highway guardrails, vehicles, and furniture, home appliances, decorations.

- 7072 aluminum: low electrode potential, mainly used for anti-corrosion covering leather, also suitable for heat exchanger fins, air conditioner aluminum foil, and ultra-thin strips.

- 7075 aluminum: one of the alloys with the highest strength in aluminium alloy, but the corrosion resistance is not good. Suitable for aircraft, ski poles, and thick plate forgings.

The main applications of aluminum profiles:

- Architectural aluminum profiles (doors, windows, curtain walls).

- Radiator aluminium profile.

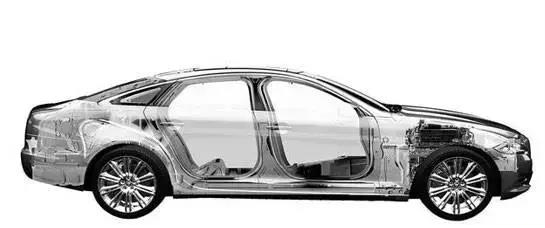

- General industrial aluminum profiles: mainly used in industrial manufacturing, such as automated machinery and equipment, skeletons, etc., can be customized by mold opening.

- Aluminim alloy profiles for rail vehicle structure: mainly used in the manufacture of rail vehicle bodies.

- Decorate aluminum profiles, make aluminum alloy face frames, and mount various decorative paintings.

- Appearance aluminum profiles are mainly used in home appliances or communication industries, such as mobile hard disks, mobile power supplies, TV sets, monitors, and other internal structures and external decoration.

Choose a good aluminum profile manufacturer

For aluminum processing parts such as aluminum profiles, good aluminum profile manufacturers can take into account the use of aluminium profiles and what may happen from the product design stage. And according to the requirements of the product, the most suitable aluminum material is selected for the processing of aluminum profiles.

At the end of the article, I recommend CHAL to you, we are a professional manufacturer of aluminium profiles, aluminum machining parts, and we have been providing reliable aluminium profiles to more than hundreds of companies all over the world. If you want to buy the best aluminum profiles, then we will be your best choice.