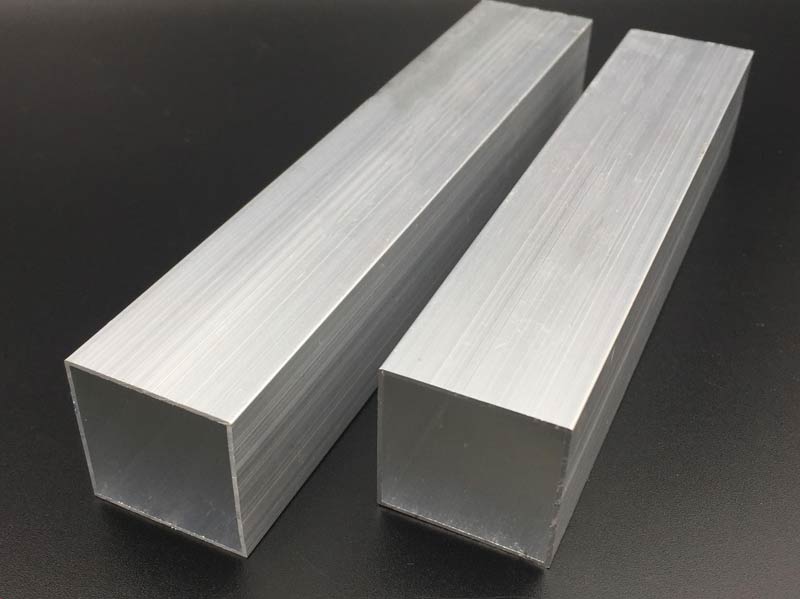

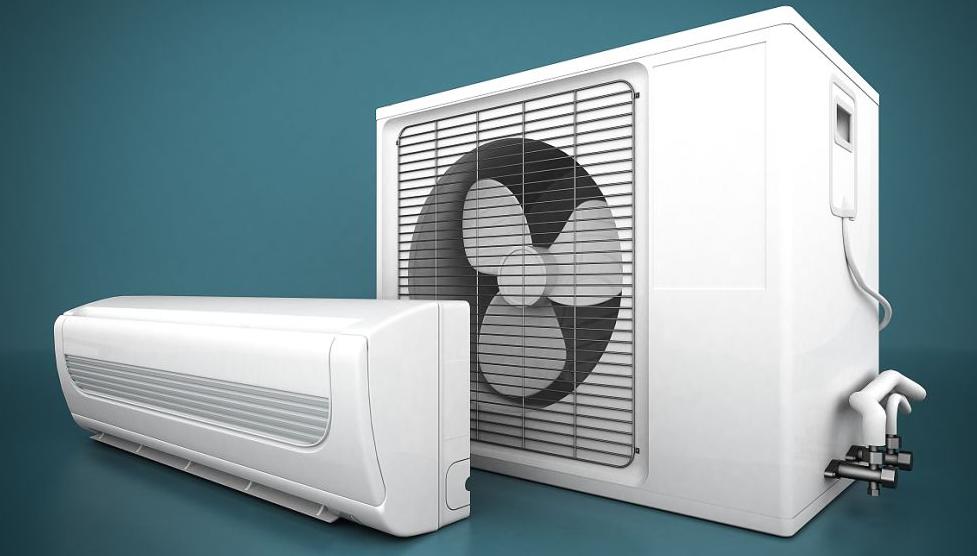

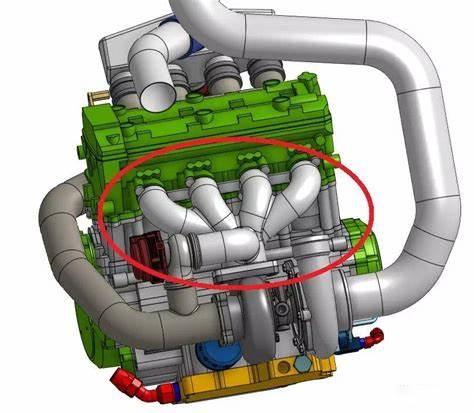

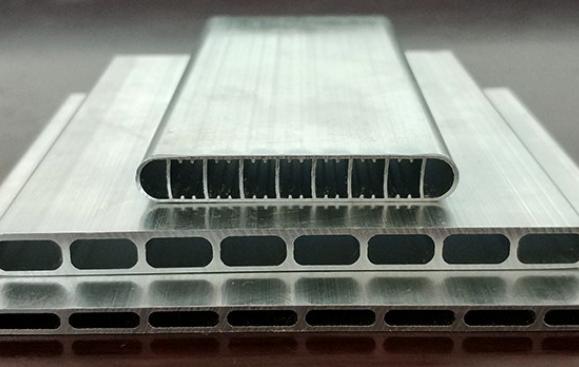

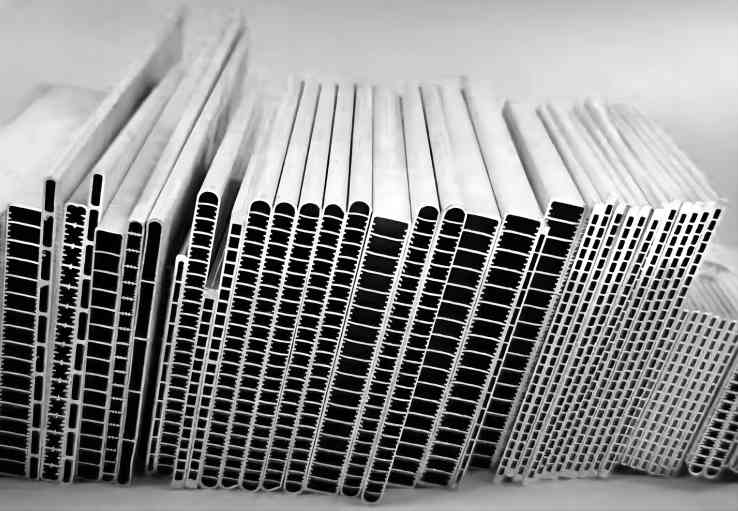

Aluminum multi-port extrusions are versatile components used in various industries, such as automotive, HVAC (Heating, Ventilation, and Air Conditioning), and refrigeration. The most common multi-port extrusion is an MPE tube. They provide an efficient way to transfer fluids, gases, or heat in complex systems. However, like any industrial process involving metalworking, working with aluminum multi-port extrusions demands careful attention to safety. In this article, we will delve into the critical safety considerations that must be taken into account when working with aluminum multi-port extrusions.

1. Personal Protective Equipment (PPE) When Working with Aluminum Multi-Port Extrusions

Personal Protective Equipment is the first line of defense for workers handling aluminum multi-port extrusions. Employees should wear safety glasses or goggles to protect their eyes from potential flying particles or metal chips. Gloves made of appropriate materials, such as cut-resistant or heat-resistant gloves, are essential to shield hands from sharp edges and hot surfaces. In situations that involve welding or soldering, workers should also wear protective clothing and respiratory protection to prevent inhalation of fumes or dust.

2. Proper Handling and Lifting Techniques When Working with Aluminum Multi-Port Extrusions

Aluminum multi-port extrusions can come in various shapes and sizes, some of which can be heavy and cumbersome to handle. Workers should be trained in proper lifting techniques to avoid strains, sprains, and back injuries. Mechanical lifting aids, such as hoists or cranes, should be used when dealing with larger or heavier extrusions to minimize the risk of accidents during handling and installation.

3. Ventilation When Working with Aluminum Multi-Port Extrusions

Extrusion processes involving welding, soldering, or cutting can release fumes and gases. Adequate ventilation is crucial to ensure a safe working environment. Local exhaust ventilation systems can effectively remove hazardous airborne substances, protecting workers from potential respiratory issues and health hazards.

4. Fire Safety When Working with Aluminum Multi-Port Extrusions

Aluminum is a combustible material, and sparks generated during welding or cutting can pose fire risks. A comprehensive fire safety plan should be in place, including the presence of fire extinguishers, fire blankets, and an emergency evacuation procedure. Workers should be trained in fire safety protocols to respond quickly and efficiently to any potential fire incidents.

5. Electrical Safety When Working with Aluminum Multi-Port Extrusions

When using electrical equipment for welding or other processes, it is essential to adhere to electrical safety practices. Faulty equipment or improper electrical connections can lead to electrical shocks or even fires. Workers should be trained to handle electrical equipment safely and to identify potential hazards associated with electricity.

6. Cutting and Machining Safety When Working with Aluminum Multi-Port Extrusions

Cutting and machining aluminum multi-port extrusions require proper tools and cutting techniques. Workers should use appropriate cutting fluids to cool and lubricate the cutting process and prevent overheating. Using the correct cutting tools and techniques minimizes the risk of accidents, such as metal fragments flying off during cutting.

7. Material Compatibility When Working with Aluminum Multi-Port Extrusions

Ensure that any lubricants, cutting fluids, or cleaning agents used during the extrusion process are compatible with aluminum. Some chemicals can react with aluminum, leading to corrosion or weakening of the extrusions. Always follow the manufacturer’s recommendations for using compatible materials and fluids.

8. Inspection and Quality Control When Working with Aluminum Multi-Port Extrusions

Regular inspections of the extrusions and the tools used in the process are essential to identify any defects or issues that could compromise safety. Quality control measures should be in place to ensure that the extrusions meet the required specifications and standards, minimizing the risk of using faulty or substandard components.

9. Training and Competence When Working with Aluminum Multi-Port Extrusions

Proper training is vital for all workers involved in the handling and processing of aluminum multi-port extrusions. Training should cover safety procedures, equipment operation, material compatibility, and emergency response plans. Competent workers are better equipped to perform tasks safely and efficiently, reducing the likelihood of accidents.

10. Housekeeping When Working with Aluminum Multi-Port Extrusions

Maintaining a clean and organized work area is essential for safety. Removing debris, metal shavings, or tripping hazards reduces the risk of accidents and ensures a safe working environment for all employees.

Conclusion

In conclusion, working with aluminum multi-channel tubes offers numerous benefits, but it is essential to prioritize safety throughout the process. Adherence to proper safety measures, such as wearing appropriate PPE, providing adequate ventilation, and implementing fire safety protocols, is crucial to protect workers and maintain a safe work environment. Ergonomic practices, electrical safety precautions, and proper material handling are equally important aspects of working safely with aluminum multi-channel tubes. By investing in worker training and regular inspections, industries can ensure that their workforce operates with the utmost safety, reducing the likelihood of accidents and promoting a culture of safety-first practices.