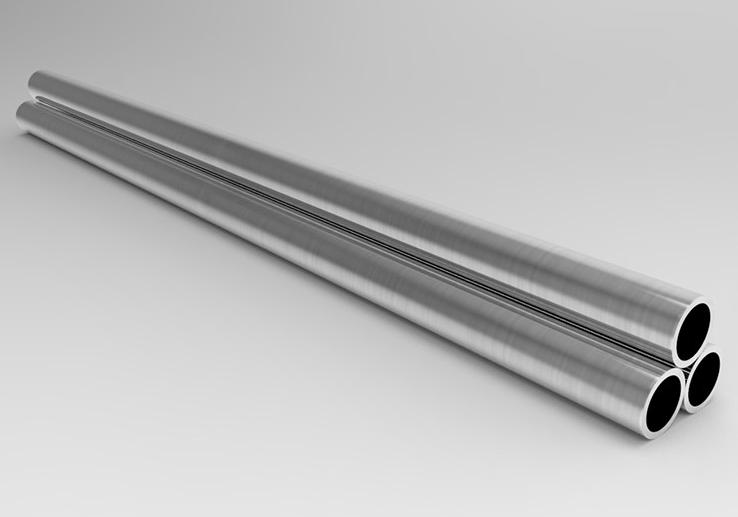

Extruded aluminum tubes are a versatile and reliable material with a wide range of applications. They are lightweight, strong, durable, and versatile, making them a popular choice for a variety of industries.

Manufacturing of Extruded Aluminum Tubes

- Raw materials: The most common raw materials used for extruded aluminum tubes are aluminum ingots, lubricants, and dies.

- Aluminum ingots: Aluminum ingots are blocks of aluminum that are melted and cast into billets. The billets are then hot rolled to a uniform thickness.

- Lubricants: Lubricants are used to reduce friction between the billet and the die during the extrusion process. The lubricants also help to prevent the billet from sticking to the die.

- Dies: Dies are the molds that give the extruded tube its shape. Dies are made of a hard material, such as steel or tungsten carbide, and they have the desired cross-sectional shape of the tube.

- Preparation of the raw materials: The aluminum ingots are melted and cast into billets. The billets are then hot rolled to a uniform thickness. This process helps to ensure that the billet is strong enough to withstand the forces of extrusion.

- Extrusion: The hot-rolled billet is then placed in the extrusion press. A ram forces the billet through a die, which shapes it into a tube. The die is made of a hard material, such as steel or tungsten carbide, and it has the desired cross-sectional shape of the tube.

- Extrusion press: The extrusion press is a large machine that uses a hydraulic ram to force the billet through the die. The press must be able to withstand the high pressures and temperatures generated during the extrusion process.

- Die: The die is a critical component of the extrusion process. It must be made of a hard material that can withstand the high pressures and temperatures of the process. It must also have the precise cross-sectional shape of the desired tube.

- Extrusion process: The extrusion process is a continuous process. As the billet is forced through the die, it is continuously shaped into a tube. The tube is then cooled and trimmed to length.

- Post-processing: The tube may be heat treated to improve its strength and durability. It may also be anodized to protect it from corrosion.

- Heat treatment: Heat treatment is a process that is used to change the properties of a metal. In the case of extruded aluminum tubes, heat treatment can be used to improve the strength and durability of the tube.

- Anodizing: Anodizing is a process that is used to create a protective coating on a metal surface. The anodized coating protects the tube from corrosion and wear.

Applications of Extruded Aluminum Tubes

Extruded aluminum tubes are used in a wide variety of applications, including:

Construction

- Windows and doors: Extruded aluminum tubes are used in the frames of windows and doors. They are lightweight and strong, making them ideal for these applications. They are also corrosion resistant, which is important in areas with harsh weather conditions.

- Railings: Extruded aluminum tubes are used in railings for balconies, decks, and staircases. They are strong and durable, and they can be anodized to match the color of the building.

- Scaffolding: Extruded aluminum tubes are used in scaffolding for construction projects. They are lightweight and easy to transport, making them a convenient choice for this application.

Transportation

- Cars and trucks: Extruded aluminum tubes are used in a variety of components in cars and trucks, such as the frames, bumpers, and suspension systems. They are lightweight and strong, which helps to improve fuel efficiency and performance.

- Aircraft and spacecraft: Extruded aluminum tubes are used in a variety of components in aircraft and spacecraft, such as the wings, fuselage, and landing gear. They are lightweight and strong, and they can withstand the high temperatures and pressures of flight.

Machinery

- Hydraulic cylinders: Extruded aluminum tubes are used in hydraulic cylinders. They are strong and lightweight, and they can withstand the high pressures of hydraulic systems.

- Pneumatic actuators: Extruded aluminum tubes are used in pneumatic actuators. They are strong and lightweight, and they can withstand the high pressures of pneumatic systems.

- Conveyor belts: Extruded aluminum tubes are used in conveyor belts. They are strong and durable, and they can withstand the wear and tear of constant use.

Advantages of Extruded Aluminum Tubes

Extruded aluminum tubes offer a number of advantages over other types of tubes, including:

Lightweight: Aluminum is a very lightweight material, with a density of just 2.7 grams per cubic centimeter. This makes extruded aluminum tubes ideal for applications where weight is a concern, such as in aircraft and spacecraft, automobiles, and sporting goods.

Strong: Aluminum is also a strong material. It has a tensile strength of up to 30,000 psi, which is about twice the tensile strength of steel. This makes extruded aluminum tubes suitable for applications where strength is required, such as in construction, machinery, and furniture.

Durable: Extruded aluminum tubes are corrosion-resistant and can withstand a wide range of temperatures. They are not affected by water, salt, or other chemicals, and they can withstand temperatures ranging from -200 degrees Fahrenheit to 800 degrees Fahrenheit. This makes them ideal for use in a variety of harsh environments, such as in marine applications, in the chemical industry, and in the food processing industry.

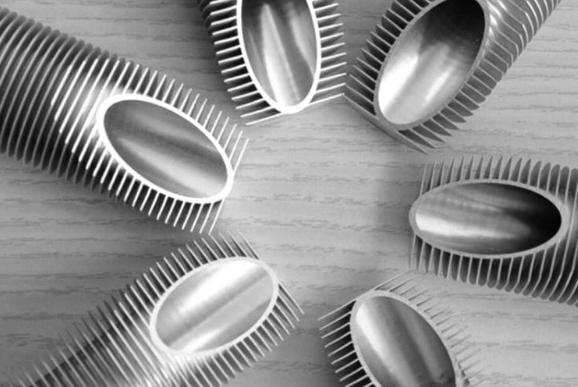

Versatility: Extruded aluminum tubes can be made in a variety of shapes and sizes. This makes them suitable for a wide range of applications, from the smallest components to the largest structures. For example, extruded aluminum tubes are used to make everything from window frames and door frames to bicycle frames and airplane fuselages.

Conclusion

Extruded aluminum tubes are a versatile and reliable material with a wide range of applications. They are lightweight, strong, durable, and versatile, making them a popular choice for a variety of industries.