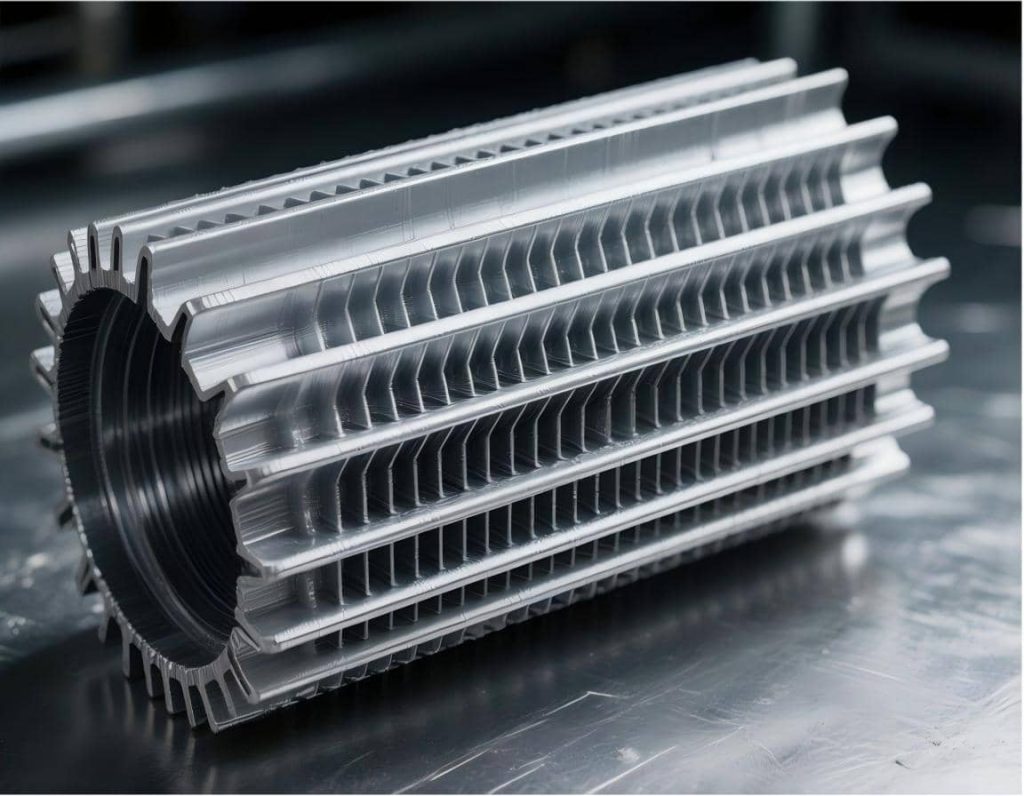

Radiators stand as indispensable components across various systems, from automotive engines to industrial machinery and electronic devices. The quest for enhanced radiator performance has spurred innovation, leading to the exploration of alternative tube designs. One such innovation gaining momentum is the adoption of oval-shaped aluminum tubes in radiator construction. This article aims to elucidate the rationale behind the utilization of oval-shaped aluminum tubes, comparing their advantages over conventional round tubes and exploring specific applications where flat-sided aluminum tubes excel.

The Advantages of Using Flat-Sided Oval Aluminum Tube in Radiator

The conventional approach to radiator construction predominantly utilized round tubes due to their ease of manufacturing and structural stability. However, the limitations posed by round tubes, particularly in terms of heat transfer efficiency and fluid dynamics, prompted engineers and researchers to explore alternative designs. The emergence of flat-sided aluminum tubes represents a paradigm shift in radiator technology, offering a myriad of benefits over their conventional counterparts:

- Enhanced Heat Transfer: The flat sides of oval tubes provide a larger surface area compared to round tubes. This increased surface area improves heat transfer efficiency, allowing for more effective cooling of the radiator fluid.

- Improved Fluid Flow: The streamlined shape of flat-sided oval tubes helps reduce fluid resistance and turbulence compared to round tubes. This smoother flow of fluid enhances the overall circulation within the radiator, optimizing cooling performance.

- Space Efficiency: Flat-sided oval tubes can be arranged more closely together within the radiator core, maximizing the effective use of available space. This compact design allows for a greater number of tubes to be incorporated into the radiator, increasing the overall heat transfer capacity.

- Strength and Durability: Aluminum is a lightweight and durable material that offers excellent corrosion resistance. Flat-sided oval aluminum tubes provide sufficient strength while minimizing weight, ensuring the radiator’s structural integrity and longevity.

- Aesthetic Appeal: In addition to their functional benefits, flat-sided oval aluminum tubes can contribute to a sleek and modern design aesthetic in radiators. This can be important for automotive and architectural applications where appearance matters.

- Manufacturing Flexibility: Flat-sided oval aluminum tubes can be manufactured using various processes, including extrusion and forming techniques. This flexibility allows for customized designs to meet specific radiator performance and application requirements.

Overall, the advantages of using flat-sided oval aluminum tubes in radiators include improved heat transfer efficiency, enhanced fluid flow, space optimization, strength, durability, aesthetic appeal, and manufacturing flexibility. These qualities make them a preferred choice in radiator design for various industries, particularly automotive and HVAC applications.

What are the Specific Applications of Flat Sided Oval Aluminum Tubes in Radiator?

Flat-sided oval aluminum tubes find specific applications in radiator designs, especially in automotive cooling systems. Here are some specific uses:

- Automotive Radiators: Flat-sided oval aluminum tubes are commonly used in automotive radiators to enhance cooling efficiency. Their streamlined shape and increased surface area allow for better heat transfer and fluid flow, which is crucial for maintaining optimal engine temperatures in vehicles.

- Heavy-Duty Vehicles: Radiators in heavy-duty vehicles such as trucks, buses, and construction equipment often require robust cooling systems to handle the higher thermal loads generated by larger engines and heavier workloads. Flat-sided oval aluminum tubes can provide the necessary heat transfer capacity and durability required for these applications.

- High-Performance Vehicles: Performance vehicles, including sports cars and racing cars, demand superior cooling performance to withstand the extreme heat generated during high-speed driving or track events. Flat-sided oval aluminum tubes can help optimize heat dissipation and fluid flow in radiators designed for these vehicles, contributing to enhanced engine performance and reliability.

- Electric Vehicles (EVs): Electric vehicles rely on efficient cooling systems to manage the heat generated by electric motors, batteries, and power electronics. Flat-sided oval aluminum tubes can be used in EV radiators to improve thermal management and ensure the reliable operation of critical components, thereby extending the vehicle’s range and lifespan.

- Specialized Cooling Systems: In addition to automotive applications, flat-sided oval aluminum tubes may also be utilized in specialized cooling systems for industrial equipment, HVAC (Heating, Ventilation, and Air Conditioning) systems, and power generation facilities. These tubes offer versatility and performance benefits that make them suitable for various cooling applications across different industries.

Overall, the specific applications of flat-sided oval aluminum tubes in radiators are diverse and encompass a wide range of automotive and industrial cooling systems where efficient heat transfer, fluid flow, and durability are paramount.

Conclusion

In conclusion, the adoption of flat-sided aluminum tubes represents a paradigm shift in radiator technology, offering unparalleled advantages in terms of performance, efficiency, and versatility. By leveraging the unique geometric properties of oval-shaped tubes, radiator manufacturers can enhance heat transfer rates, optimize fluid dynamics, and reduce energy consumption across a spectrum of applications. As the demand for more efficient and sustainable cooling solutions continues to grow, flat-sided aluminum tube suppliers will play a pivotal role in driving further advancements in radiator design, ushering in a new era of efficiency and reliability in thermal regulation.