Drawn seamless aluminum round tube is a popular choice for fuel lines in various applications, from automobiles and motorcycles to industrial machinery. This article explores the manufacturing process, benefits, and considerations for using drawn seamless aluminum round tubes in fuel lines.

How Does Drawn Seamless Aluminum Round Tube Manufactured?

The manufacturing process of drawn seamless aluminum round tubes involves several meticulous steps to ensure their quality and functionality.

Types of Aluminum Used:

Common aluminum alloys used for drawn seamless aluminum round tube in fuel lines include:

5052: Offers good corrosion resistance, weldability, and workability. Suitable for low and medium-pressure fuel lines.

6061: Provides a good balance of strength, corrosion resistance, and machinability. Often used for general-purpose fuel lines.

Techniques to Ensure Seamless Construction:

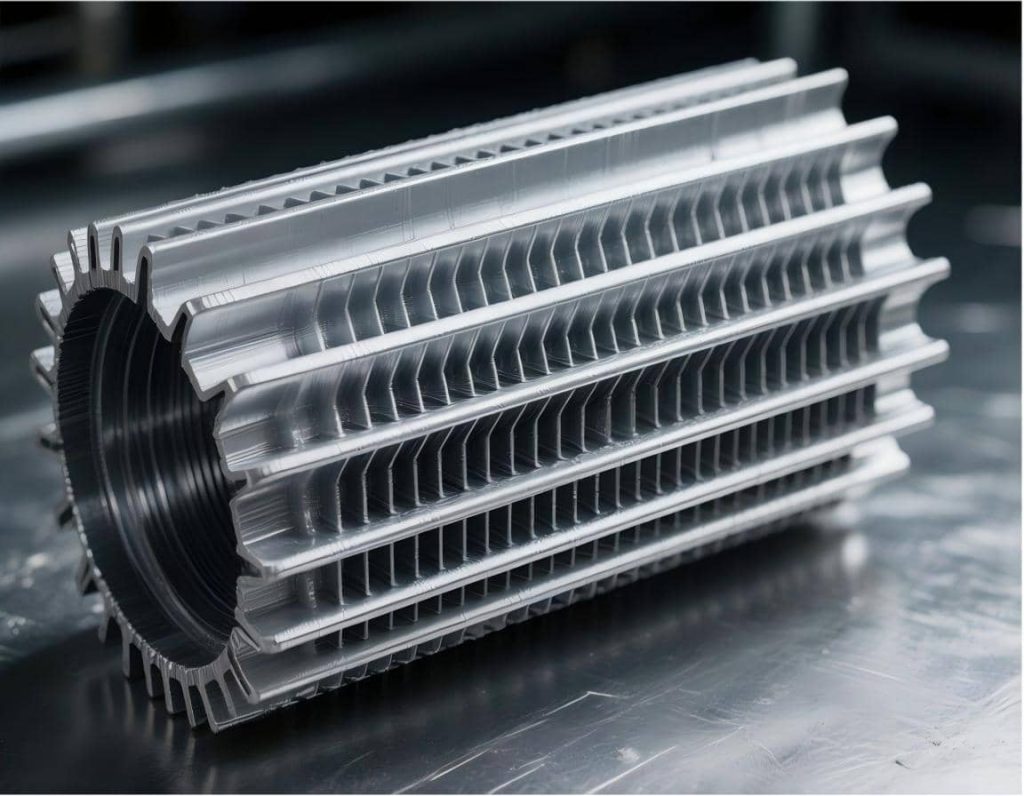

The process begins with the selection of high-quality aluminum billets, which are heated and pierced to form a hollow shell. This shell is then drawn through a series of dies to achieve the desired diameter and thickness. The seamless construction eliminates the risk of leakage or weak points, ensuring reliable performance under varying conditions.

However, manufacturers may employ additional techniques to ensure consistent quality:

- Ultrasonic Testing: This non-destructive method uses sound waves to detect any internal cracks or imperfections in the tube wall.

- Eddy Current Testing: This technique uses electromagnetic fields to identify surface defects on the tube.

Surface Treatments:

Surface treatments play a crucial role in enhancing the performance, durability, and appearance of drawn seamless aluminum round tubes used in fuel lines. Some common surface treatments include:

- Anodizing: An electrochemical process that forms a protective oxide layer on the surface of aluminum. Anodizing increases corrosion resistance, improves wear resistance, and provides a decorative finish. It can also be dyed to achieve various colors.

- Powder Coating: A dry finishing process where finely ground particles of pigment and resin are electrostatically charged and sprayed onto the aluminum surface. The coated tubes are then cured under heat, forming a durable, uniform, and protective layer. Powder coating offers excellent corrosion resistance, UV protection, and a wide range of color options.

- Painting: Traditional liquid paint can be applied to aluminum tubes to provide corrosion protection and aesthetic appeal. Primers and topcoats are used to enhance adhesion, durability, and resistance to environmental factors such as UV radiation and chemicals.

- Chemical Conversion Coating: Also known as chromate conversion coating, this process involves treating the aluminum surface with a chemical solution containing chromates. The coating improves corrosion resistance, paint adhesion, and electrical conductivity. It can also serve as a base for paint or other organic coatings.

- Clear Coating: A transparent protective layer applied to the aluminum surface to prevent oxidation and maintain the natural appearance of the metal. Clear coatings can be anodized, lacquered, or coated with clear sealants to provide varying levels of protection and durability.

These surface treatments not only safeguard the integrity of drawn seamless aluminum round tubes against corrosion, abrasion, and environmental degradation but also contribute to their aesthetic appeal, ensuring reliable and visually appealing fuel line systems in automotive applications.

Advantages of Using Drawn Seamless Aluminum Round Tube in Fuel Lines

Several advantages make drawn seamless aluminum round tube a preferred choice for fuel lines:

1. Lightweight Champion:

Round aluminum drawn tubes are significantly lighter than steel tubes commonly used in vehicles and machinery. This translates to a lighter overall weight, which offers several benefits:

- Improved Fuel Efficiency: In vehicles, lighter components mean less energy is required to move the same distance, leading to better fuel economy.

- Increased Payload Capacity: Lighter frames in machinery allow for carrying heavier loads without compromising performance.

- Enhanced Maneuverability: Reduced weight can improve handling and agility, especially in vehicles.

2. Durability Built to Last:

The cold drawing process strengthens the aluminum, making these tubes highly resistant to bending, warping, and impacts. This translates to:

- Longevity: Drawn aluminum tubes can withstand years of operation under demanding conditions.

- Reduced Maintenance: Their inherent strength minimizes the need for frequent repairs or replacements.

- Reliable Performance: You can expect consistent performance over the lifespan of the tubes.

3. Corrosion Champions:

Aluminum naturally forms a protective oxide layer that shields it from rust and corrosion. This makes drawn aluminum tubes ideal for:

- Fuel Systems: They can handle various fuels, including gasoline, diesel, and biofuels, without succumbing to corrosion.

- Harsh Environments: Their resistance to salt, water, and other corrosive elements makes them suitable for marine applications or use with road salts.

- Long-Term Exposure: They maintain their integrity even when exposed to harsh weather conditions for extended periods.

4. Flexible Design Solutions:

Round shapes offer inherent strength and can be easily bent or formed into various configurations without compromising their structural integrity. This allows for:

- Adaptability: Drawn aluminum tubes can be designed to fit seamlessly into diverse fuel system layouts.

- Customization: They can be formed into specific shapes to meet the unique requirements of different applications.

- Simplified Manufacturing: Their formability allows for efficient and cost-effective fabrication of complex fuel system components.

In conclusion, round aluminum drawn tubes offer a compelling combination of lightweight construction, exceptional durability, outstanding corrosion resistance, and design flexibility. These advantages make them a superior choice for various applications, from fuel systems in vehicles and machinery to components exposed to harsh environments.

Considerations for Using Drawn Seamless Aluminum Round Tube in Fuel Lines

Here are some key considerations for using drawn seamless aluminum round tubes in fuel lines:

- Wall Thickness: The wall thickness of the tube needs to be sufficient to handle the fuel pressure within the system. Thicker walls can withstand higher pressures but add weight.

- Fuel Compatibility: Not all aluminum alloys perform equally with all types of fuel. Certain alloys might be more susceptible to corrosion with specific biofuels or ethanol blends.

- Bending Radius: The cold drawing process strengthens the aluminum, but it can also make it less ductile (bendable). Bending the tubes beyond their recommended radius can create stress points and weaken the structure.

- Joining Techniques: Welding aluminum requires specific techniques and expertise to avoid compromising the strength and corrosion resistance of the joint. Alternative joining methods like swaging or crimping might be necessary depending on the application.

- Temperature Fluctuations: Aluminum conducts heat well, which can be beneficial in some situations. However, in extremely hot or cold environments, the fuel line might require additional insulation to maintain optimal fuel temperature.

- Regulations: Specific industries, like automotive, might have regulations regarding the use of aluminum in fuel lines. Ensure the chosen alloy and tube specifications comply with any relevant safety standards.

Conclusion

Drawn seamless aluminum round tubes offer a compelling solution for fuel line applications, combining lightweight construction, corrosion resistance, and structural integrity. By understanding the manufacturing process, advantages, and considerations associated with these tubes, engineers and manufacturers can make informed decisions to optimize the performance and reliability of fuel delivery systems. If you are looking for a drawn aluminum tubing manufacturer, please feel free to contact CHAL. They are professional aluminum tube manufacturer and supplier and can provide you with reliable products and services.