Outdoor gear made from the tapered aluminum tube is changing the industry as the demand for lightweight and high-performance products continues to rise. Thinner designs improve the stability and strength of. lightweight backpacks, other backpacks, and other outdoor gear.

Tapered aluminum tubing is slowly becoming a key part of high-end outdoor manufacturers’ technology. It may be used for everything from camping bed frames to trekking poles to tent frames and outdoor furniture. What makes it able to survive under tough outdoor conditions?

The Growing Demand for Lightweight Outdoor Structures

The lightweight revolution in outdoor gear was certain to happen when every mountaineer figured out how to trim 100 ounces from a backpack and every biker looked for gear that was easier to use and more efficient.

People today don’t only want basic features anymore; they want extraordinary performance: lower weight, smaller size, and longer battery life. The market for ultralight gear has expanded by more than 15% per year, showing that this change is now happening across the board.

Innovative materials are what is driving this change. When shaped into tapered aluminum tubes, aluminum alloys are much stronger than regular steel. They make it easier to accomplish things outside and provide consumers more options for what they can do with the same amount of work.

The tapered design improves material distribution by strengthening high-stress areas and reducing extra weight from other areas. This is better than just thinning the walls or using expensive composites. This blend of strength, efficiency, and low cost is changing the way modern outdoor items are made and constructed.

Why Tapered Design Matters in Outdoor Equipment

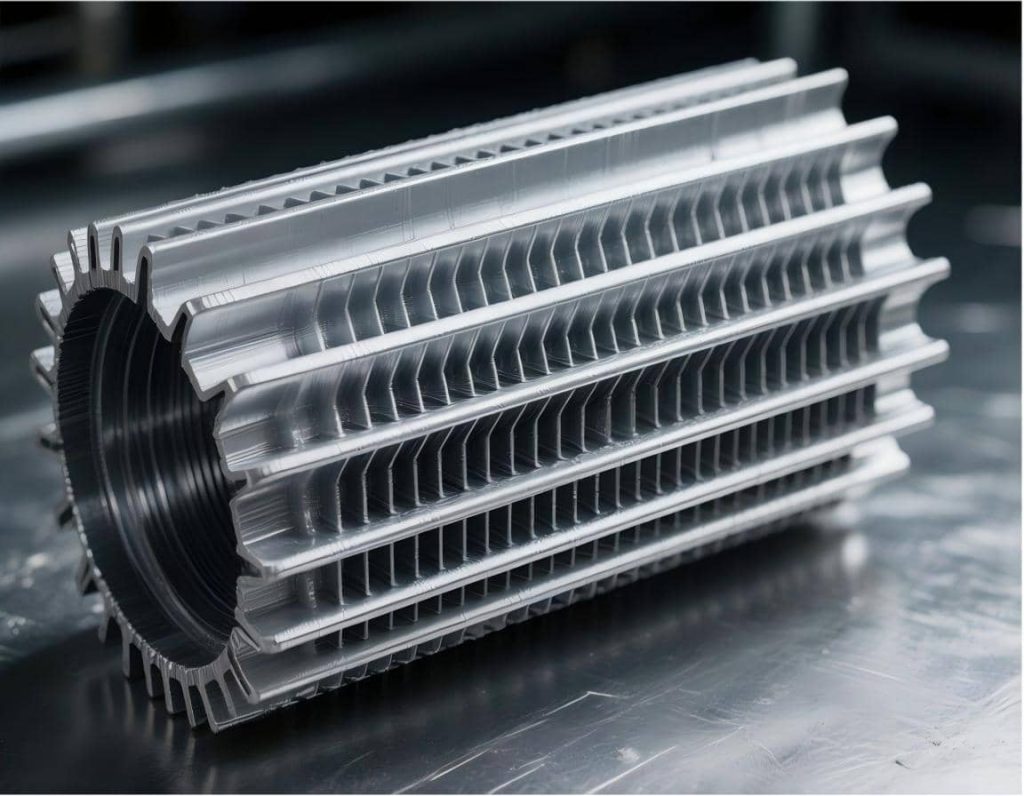

A tapered tube gradually decreases in diameter along its length, creating a smooth, conical transition that improves load distribution and bending performance.

| Feature | Tapered Tube | Straight Tube |

| Weight Distribution | Optimized; removes excess material | Uniform; often heavier |

| Strength-to-Weight Ratio | High; material used efficiently | Lower |

| Aerodynamics | Improved | Moderate |

| Aesthetic Appearance | Sleek and modern | Conventional |

In outdoor applications, this means stronger base sections that can handle high stress while maintaining lightweight upper sections for easy handling and stability.

For example:

- Tent Poles: The thicker base resists wind loads, while the tapered tip reduces weight.

- Tripods and Monopods: Provide balance and rigidity without extra bulk.

- Lighting and Flag Poles: Withstand wind pressure while reducing oscillation.

At CHAL, we assist engineers and designers get the right taper ratios, wall thicknesses, and alloy choices so that each product works the way it should with as little material waste as possible.

Advantages of Aluminum for Outdoor Applications

While the tapered geometry provides structural genius, the choice of aluminum offers the critical material properties for an outdoor lifespan.

A. Lightweight Champion

Steel is tremendously heavy, and aluminum only weighs a 1/3 as much. Double bonus: aluminum can be shaped into tapered tubes, minimizing aluminum’s weight even more, reducing fatigue and cost. 6061 and 7075 are high-strength aluminum alloys supplied by CHAL that are as strong as heavy steels, only much lighter.

B. Unmatched Corrosion Resistance

Aluminum is the best choice for outdoor use. No other material lasts as long as aluminum—steel rusts when outside. Unlike aluminum, a rusting tapered steel tube is a problem. Steel rusting is also a product that will require a hefty amount of maintenance. Tempered steel rusts fairly quickly and will require replacement. Aluminum will last for the rest of your life with minimal maintenance. Aluminum oxide layer is non corrosive and protective, making it a clear outdoor choice. Also, with taking long product life into account over steel, Aluminum is the cheaper long-term outdoor choice.

C. Versatility and Finish

Aluminum is easy to anodize and powder coat. Aside from making the metal more visually appealing, anodization and powder coating also protect the metal against abrasion and corrosion. This makes anodized aluminum tube great for anodized aluminum tube products that need to stay visually appealing for a long time.

Typical Outdoor Applications of Tapered Aluminum Tubes

Tapered aluminum tubes are widely employed in outdoor sectors, including recreational sports, professional equipment, and structural installations, due to their remarkable mix of lightweight strength, corrosion resistance, and design flexibility. The following are some of the most prevalent applications in which CHAL’s precision-engineered tubes provide substantial performance benefits.

| Application | Key Benefits of Using Tapered Aluminum Tubes | Typical Alloys Used |

| Tent Poles & Camping Frames | Lightweight and portable; excellent wind resistance; easy to assemble; maintains rigidity under stress. | 7001-T6, 6061-T6, 6063-T5 |

| Camera Tripods, Light Stands & Monopods | High stiffness-to-weight ratio; vibration reduction for stable imaging; sleek anodized surface finish. | 6061-T6, 6063-T6 |

| Flagpoles & Outdoor Lighting Poles | Smooth tapered profile improves aerodynamics and aesthetics; excellent corrosion resistance for long-term exposure. | 6063-T6, 6082-T6 |

| Drone Arms & UAV Structural Tubes | High specific strength with minimal weight; easy to machine and join; resists fatigue during vibration. | 7075-T6, 6061-T6 |

| Kayak & Paddle Shafts, Ski Poles | Lightweight and durable; provides responsive flexibility and grip comfort; resists saltwater corrosion. | 6061-T6, 7005-T6 |

| Telescopic Masts & Extension Poles | Tapered ends ensure smooth section nesting; high bending resistance; customizable anodized or powder-coated surface. | 6063-T5, 6082-T6 |

| Portable Solar Panel Frames & Mounting Systems | Corrosion-resistant, easy to transport and install; supports long-term outdoor exposure without rusting. | 6061-T6, 6063-T6 |

| Outdoor Fitness & Sports Equipment Frames | High fatigue resistance; stable under cyclic loading; customizable in shape and finish. | 6061-T6, 6063-T5 |

| Recreational Vehicle (RV) Accessories & Roof Racks | Combines lightness with strength; supports aerodynamic designs and load-bearing requirements. | 6061-T6, 6082-T6 |

CHAL’s Value as a Tapered Aluminum Tube Supplier

As a leading aluminum tube supplier and fabricator, CHAL offers end-to-end support—from material selection and precision extrusion to custom machining, surface finishing, and OEM manufacturing.

Our Capabilities Include:

- We provide custom extrusion and drawing services for seamless and welded tapered aluminum tube in alloys like 6061, 6063, and 7075.

- CNC machining and swaging create exact, tapered transitions with close tolerances.

- For aesthetics and corrosion protection, we offer anodising, powder coating, polishing, and sandblasting surface treatments.

- Stress and buckling simulation using FEA techniques allows for engineering support. Complete technical services can be found with CHAL Service & Solutions.

Through the company’s knowledge and experience in the industry and the flexibility to tailor designs to each customer’s need, CHAL meets international standards (ASTM B221, EN 755) and guarantees the most efficient and timely international shipping and delivery of tapered aluminum tubes.

Tapered Aluminum Tube: Light, Strong, and Built for the Outdoors

Tapered aluminum tubing’s features make it great for the camping gear of the future, as well as for camping gear, telescopic lighting systems, and durable camping architecture.

CHAL wants to help designers and manufacturers rethink the possibilities when it comes to lightweight, high-precision, and sustainable aluminum.

Strong enough for the wild, refined enough for modern design.

View our complete assortment of aluminum tubing and pipes here, and for a personalized solution for your project, reach out to our specialists.