If you think about heat exchangers, automotive air conditioning, commercial HVAC systems, and industrial cooling equipment, you will think about aluminum finned tubes and aluminum micro-channel tubes. Both technologies have aluminum, which is lightweight, corrosion resistant, and has good strength. Both technologies are also common heat exchangers. However, performance, maintenance, lifecycle cost, and overall suitability for an application will be very different just by the design.

This article provides a complete “How to choose” guide for engineers, procurement teams, and system designers. Using the framework of selection, design, economics, service life, and maintenance, we explain how each tube technology performs in typical scenarios and how to make the correct decision for your system.

Understanding the Fundamentals Before Selection

Before diving into application-based recommendations, it is essential to understand the core characteristics of each tube structure.

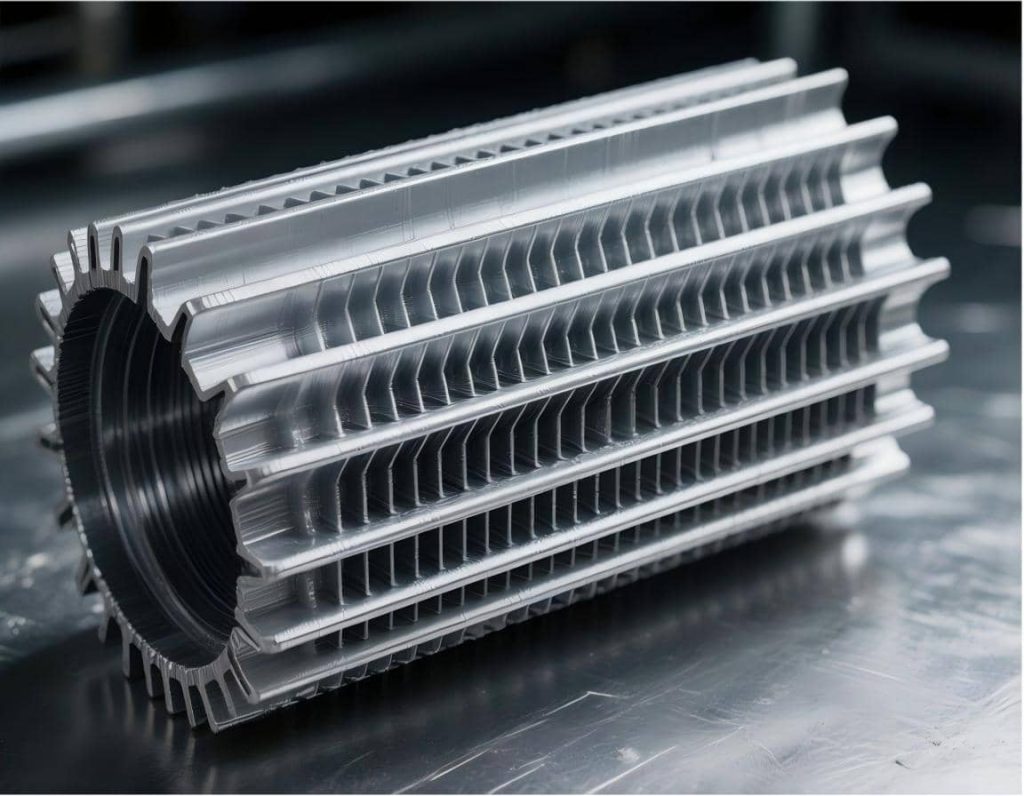

What Is an Aluminum Finned Tube?

An aluminum finned tube consists of a traditional round tube with external fins mechanically bonded or extruded together.

Advantages:

- Strong resistance to fouling and contamination

- Excellent maintainability, easy to clean

- Robust mechanical strength

- Suitable for dusty, corrosive, or harsh industrial environments

- Proven technology with a long track record

Limitations:

- Larger footprint

- Lower heat transfer efficiency compared with microchannel

- Requires more material and refrigerant

- Higher fan power due to a larger frontal area

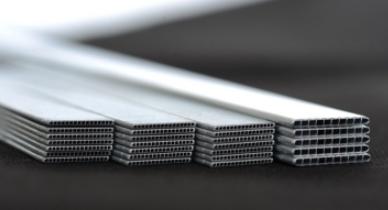

What Is an Aluminum Microchannel Tube?

Micro-channel tubes are flat, multi-port extruded aluminum profiles containing many small internal channels.

Advantages:

- Very high heat transfer efficiency

- Compact design and lightweight

- Less aluminum material and reduced refrigerant charge

- Excellent thermal uniformity

- Ideal for compact systems or where efficiency regulations are strict

Limitations:

- More sensitive to dirt, dust, and clogging

- Higher precision and manufacturing requirements

- Potential corrosion risk if not properly protected

- Harder to repair once leakage occurs

Understanding these fundamental trade-offs is the first step in selecting the correct technology.

How to Choose Based on Application Requirements

1. Automotive Air Conditioning (AC)

What automotive AC systems need:

- Lightweight structure

- High cooling efficiency

- Compact size for limited engine bay space

- Low refrigerant consumption

- Low manufacturing cost at large production volumes

Why microchannel is usually the preferred choice?

Microchannel tubes allow producers to make smaller, lighter condensers and evaporators in line with modern car efficiency and fuel-economy standards. Also, these allow for a smaller refrigerant charge, which is a major advantage for automotive cooling cycles.

When finned tubes are still relevant:

- Heavy-duty trucks operating in dusty environments

- Off-road vehicles with high vibration and contamination levels

In these scenarios, clogging resistance and mechanical durability outweigh efficiency benefits.

Selection Checklist:

- If lightweight and compact design are priorities → choose aluminum microchannel tubes

- If durability in harsh environments is a priority → choose aluminum finned tubes

2. Commercial HVAC Systems

Building HVAC systems—rooftop units, chillers, VRF systems—prioritize long-term efficiency, predictable operating cost, and reliability.

Why do many commercial HVAC systems adopt microchannel technology?

- High EER/SEER energy ratings

- Reduced coil size

- Lower refrigerant cost

- Better thermal efficiency under controlled environments

When finned tubes remain advantages:

- In large outdoor air-cooled systems susceptible to fouling

- Facilities with poor filtration or large airflow requirements

- Systems requiring easier field cleaning and maintenance

Regulatory Influence:

Modern HVAC efficiency standards (EER/SEER) increasingly favor microchannel coils because they deliver higher performance with less refrigerant.

Selection Summary:

- Buildings with good air filtration → microchannel tube recommended

- Facilities in dusty or industrial zones → finned tube preferred

3. Industrial Cooling Systems

Industrial environments pose the greatest challenges: chemical vapors, dust, vibration, and variable water or air quality.

Key industry needs:

- High corrosion resistance

- Easy maintenance and low downtime

- Long service life

- Robustness under harsh conditions

Why finned tubes dominate industrial cooling:

- Resistant to fouling

- Easy to clean or mechanically brush

- More tolerant of water quality variations

- Fewer leakage risks

Microchannel tubes can offer high efficiency but often struggle with clogging, cleaning difficulty, and corrosion unless protective coatings are applied.

Final Recommendation:

For most industrial environments, aluminum finned tubes remain the safer and more reliable choice.

How to Design an Optimal Heat Exchanger?

1. Thermal Performance Design

Micro-channel tubes boost heat transfer by increasing surface area and lowering thermal resistance.

Finned tubes rely on fin spacing, fin geometry, and air velocity to enhance performance.

Key design factors:

- Internal channel dimensions

- Wall thickness

- Airside fin geometry

- Pressure drop vs heat transfer balance

A well-designed microchannel condenser can achieve up to 30–40% higher efficiency than conventional finned-tube coils.

2. Mechanical and Structural Design

- Microchannel tubes require precise extrusion and uniform brazing.

- Finned tubes withstand higher mechanical stress and tolerate larger temperature swings.

- High vibration environments favor mechanically expanded finned tubes.

The choice of design must align with mechanical stress conditions.

3. Environmental Considerations

- Salt spray and chemical environments require protective coatings for microchannel tubes.

- Finned tubes may also benefit from hydrophilic or epoxy coatings but are generally more tolerant.

- Temperature and refrigerant compatibility must be considered in early design stages.

How to Evaluate Economic Feasibility?

1. Initial Cost Comparison

Microchannel tubes often have slightly higher manufacturing costs due to extrusion precision and brazing requirements. However, they reduce:

- aluminum consumption

- refrigerant charge

- system size

Finned tubes may have lower tube cost but require more material and larger coil assemblies.

2. Operating Cost Advantages

- Microchannel tubes provide lower fan energy consumption due to lower air-side pressure drop.

- Enhanced heat transfer reduces compressor workload and power consumption.

- Finned tubes require more airflow and more refrigerant, increasing operating expenses.

3. Life-Cycle Ownership Cost

- Maintenance, cleaning, and durability must be included.

- Microchannel → higher efficiency, lower refrigerant cost, but higher repair difficulty.

- Finned tube → easier cleaning, longer lifespan in harsh conditions, lower unexpected downtime.

Your final economic decision depends on the expected operating environment and maintenance capability.

How to Predict Service Life and Reliability?

1. Corrosion Performance

Resistance to corrosion plays an important role in determining long-term reliability. Formicary corrosion, pitting, galvanic corrosion, and other protective coatings are more common in microchannel tubes. Thin walls and several internal ports make them more susceptible to corrosion. Compact heat exchangers are more prone to structural corrosion. Conversely, aluminum finned tubes have larger airflow channels and concentrated stress lines, which minimize moisture retention and corrosion. Their thicker tubes and simpler designs make them more predictable in corrosive outdoor conditions.

2. Fatigue Resistance

Determining factors of how a tube performs under vibration. Pressure cycling and thermal expansion are known as fatigue resistance. Microchannel tubes withstand fatigue well in automotive applications due to the stable airflow of the vehicle environment. In industrial cooling applications, finned tubes perform better under the harsh conditions of strong vibrations, temperature shock, and rapid pressure changes. Their thick walls and robust structures of the tubes reduce the accumulation of fatigue. Over time, this stops the operational life from decreasing due to cracking.

3. Environmental Durability

Service life of a product is highly dependent on environmental factors.

- Dusty parts and settings: Finned tubes are preferred due to their ability to resist clogging and are easy to clean Dusty parts and settings: Finned tubes are preferred due to their ability to resist clogging and are easy to clean.

- Coastal and high humidity areas: Microchannel tubes with anti-corrosion coating work great, but finned tubes are still a great option.

- Chemical and industrial environments: Finned tubes perform better unless microchannel tubes have full corrosion protection.

How to Plan Maintenance and Control Long-Term Costs?

1. Finned Tube Maintenance

Maintaining tube heat exchangers is simpler than others. The structures have a strong mechanical design along with a direct, unimpeded airflow. Routine maintenance is safe against tube deformation and includes low-pressure water washing, mild chemical usage, and mechanical brushing. Greater fin spacings have a lower tendency to accumulate dust and are less prone to air-side clogging. This is especially beneficial for outdoor HVAC systems and industrial plants. Maintenance is cost-effective and can generally be performed with low downtimes because leak detection is straightforward, and repairs, including tube plugging and localized welding, can almost always be done right at the location.

2. Micro-channel Tube Maintenance

Planned maintenance is required for microchannel coils. With narrow flow passages, these coils are more sensitive to contamination than their counterparts. Both the refrigerant and air sides of the coils need their filtration systems managed; otherwise, a pressure drop could occur. In coastal or corrosive conditions, protective coatings are a must for long-term reliability. Repairs for leaks are challenging because of the thin walls along with microchannel tubes. Integrated coils can be more complicated to repair, and in many cases, a complete coil replacement is more practical than a localized repair. High priority is placed on preventive protection and proactive monitoring.

3. Maintenance Cost Analysis

From a long-term point of view, cleaning and maintenance are easier with finned tubes rather than with microchannel tubes, so finned tubes are recommended for dusty and harsh environments. Microchannel tubes are more efficient and provide the best cost-performance benefits in environments where there is controlled corrosion as well as mechanical damage to the tubes.

FAQ: Frequently Asked Questions

1. Which is more efficient—aluminum finned tube or microchannel tube?

Microchannel tubes are typically more efficient due to their multi-port design and high surface-to-volume ratio.

2. Are microchannel coils suitable for industrial cooling systems?

Generally no. Harsh industrial environments favor finned tubes due to their resistance to fouling and easier cleaning.

3. Does microchannel technology reduce refrigerant usage?

Yes. Microchannel systems can reduce refrigerant charge by 40–60%.

4. Which one lasts longer in coastal or corrosive environments?

Finned tubes usually have longer service life unless microchannel tubes are coated with high-quality anti-corrosion layers.

5. Can microchannel heat exchangers be repaired easily?

Repairs are difficult. Most damaged microchannel coils require full replacement.

6. What is the most cost-effective option for commercial HVAC?

Microchannel is best for efficiency; finned tubes are best for durability and serviceability. Selection depends on site conditions.