Aluminum tube buyers will often put their attention on aspects such as price, outer diameter, and surface finish. However, one of the most important parameters defining performance and cost parameters for aluminum tubes is “aluminum tube thickness.” Knowing about wall thickness will help avoid costly mistakes and ensure intended performance, whether needing a thin-wall aluminum tube for lightweight assemblies or a thick-wall aluminum tube for structural reinforcement.

Here we cover 20 critical questions on wall thickness ranging from the most fundamental questions, through application, and sense the cost will entail. Each question aims to provide practical guidance and hopefully streamline your decision-making process.

Fundamental Concepts and Specifications

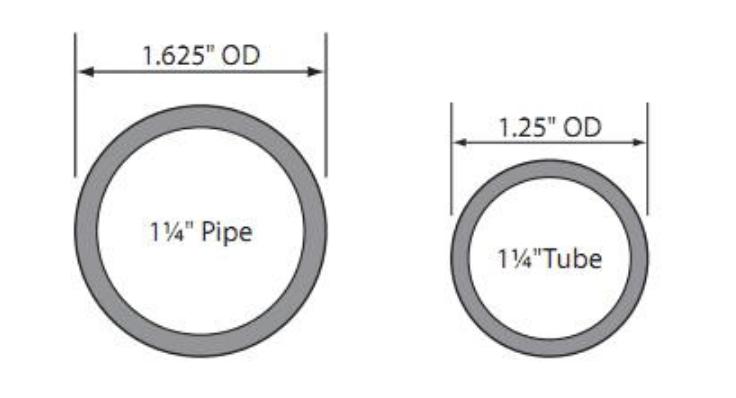

1. How are Aluminum Tubes Specifications Interpreted, and What is the Importance of the Thickness of the Material?

Specifications for aluminum tubes are communicated in three dimensions: Outside Diameter (OD), Inside Diameter (ID), and wall thickness (considerably the most important). This is because wall thickness directly determines the tube’s strength and rigidity, and conversely, the weight. For example, ‘25.4 × 2.0 × 6000 mm’ indicates a tube that is 25.4 mm OD, 2.0 mm thickness and 6 meters in length.

Among the four tube dimensions, wall thickness directly and significantly addresses weight, load-bearing, and machining. For tubes of equal radial construction, strengthened radial construction will perform similarly and bear a radically higher weight than weakened construction, which will perform less, and bend more easily.

In summary, the performance cost of construction is a greater determinant of its wall thickness.

aluminum pipe OD and aluminum tube OD

2. What is “nominal wall thickness” vs. “actual wall thickness,” and why is there a difference?

Nominal wall thickness is the intended wall thickness dimension defined in the design or a purchase order. This is the thickness the manufacturer will aim for. Actual wall thickness is the measured thickness of the tube. These two values rarely match exactly because of the extruding or drawing manufacturing limitations. The difference is a tolerance which is a value in quality control.

As an example, a 2.0 mm nominal wall should have a real thickness of 1.95 mm or 2.05 mm in thickness, which is normal if the thickness is in a tolerance limit. Procurement managers should know and understand the nominal values are only theoretical while the actual performance is defined by what is delivered.

3. What is meant by thickness tolerance and why is it more critical than thickness itself?

Thickness tolerance is the maximum allowable variation from the nominal. For instance, two suppliers might quote 2.0 mm wall tubes, but one guarantees ±10% and the other ±7.5%. The latter is more preferable.

| Nominal Wall Thickness | ASTM B241 Tolerance |

| 1.5–3.0 mm | ±10% |

| 3.0–10.0 mm | ±7.5% |

This implies that withholding ASTM standards for an agreed-upon 2.0 mm tube can end up being 1.8–2.2 mm. The less lenient the tolerance is, the more a customer can depend upon it.

When it comes to procurement, more often than not, tolerance is the more critical aspect compared to the nominal value.

4. What is “eccentricity”, and why can it be detrimental?

Eccentricity describes a tube’s wall where unevenness occurs, one side being thicker and the other side thinner. Even if the average thickness satisfies the requirements, excessive localized thinness will create a potential leak on a pressure pipe or a weak point in a structural part. In structural components where this is visible, it will be deemed unfit aesthetically.

The situation is exacerbated in a thin-walled aluminum tube, where slight unevenness will drastically undermine performance. Thus, eccentricity is a clear indicator of a poorly manufactured product.

5. What are the distinctions of wall thickness requirements between GB, ASTM, and EN?

Because tolerances can be wider, the GB (China) specification can be used for more cost-sensitive engineering works.

When it comes to GB, ASTM has the most stringent requirements, and this is even more pronounced for aerospace engineering and pressure vessel components.

In the EN specification, there is a particular emphasis placed on achieving a balance between mechanical performance and the corresponding dimensional stability.

As a first step toward assessing supplier competitiveness, always check the standard that is adhered to. A given standard is also most likely the reason for any price variance.

Performance and Cost

6. What simple concepts must be understood regarding how wall thickness impacts cost and weight?

This principle is quite basic, and easy to understand. Simply put, for the materials to use more of the cost will increase, because of the additional weight that it will have to carry.

| OD | Wall Thickness | Weight (kg/m) |

| 25 mm | 1.5 mm | 0.77 |

| 25 mm | 3.0 mm | 1.45 |

Consider the instance where you are sourcing a heavy-wall aluminium tube. Because of the more complex extrusion or drawing process for a heavy-wall aluminium tube, you will pay for the use of more material. In fact, for a large volume of the order, the cost difference will be significant. Therefore, it is very important for the application that you do not over-specify the wall thickness to prevent the extra cost.

7. Impact of wall thickness on pressure resistance.

The thickness of a wall has a direct influence on the internal pressure resistance. From Barlow’s equation:

- P=(2×σ×t)/D

- Where P = pressure, σ = strength of the material, t = thickness, D = outside diameter.

A thicker wall provides a higher pressure rating. This is the reason heavy-wall aluminum tubes are used for hydraulics, whereas thin-wall aluminum tubes are used for hydraulic air systems which work at low pressure.

8. Does a thicker wall mean a higher quality aluminum tube?

Not necessarily. Quality is based on how well a product is suited for its intended use. A thicker-walled aluminum tube is indeed stronger, but the additional weight and cost must also be considered. This matters in applications such as drone frames and bicycle components, where weight is critical, and the higher quality option is a thin-walled aluminum tube. The “best” tube achieves a specific goal with a reasonable balance of strength, cost, and weight.

9. Influence of wall thickness on the mechanical properties of aluminum tubes.

There are several mechanical properties that wall thickness has a direct influence on, including:

- Yield and ultimate tensile strength. Even though the wall thickness has no impact on the strength of the material, a thicker wall will clearly have greater cross-sectional area and thus, a greater overall load-bearing capacity.

- Stiffness and rigidity. With thinner walls, a structure will flex and deform more easily, and the walls will stretch and wrinkle. Thicker walls will increase the structure’s resistance to bending and will be crucial in preventing buckling, which is immensely important in structural applications.

- Impact resistance. Thicker structural walls will perform significantly better when it comes to impact resistance, specifically, absorbing impact energy without experiencing deformation or structural failure.

From a procurement perspective, it is important to consider dynamic loads in addition to static loads. These dynamic loads can include vibrations or cyclical pressure.

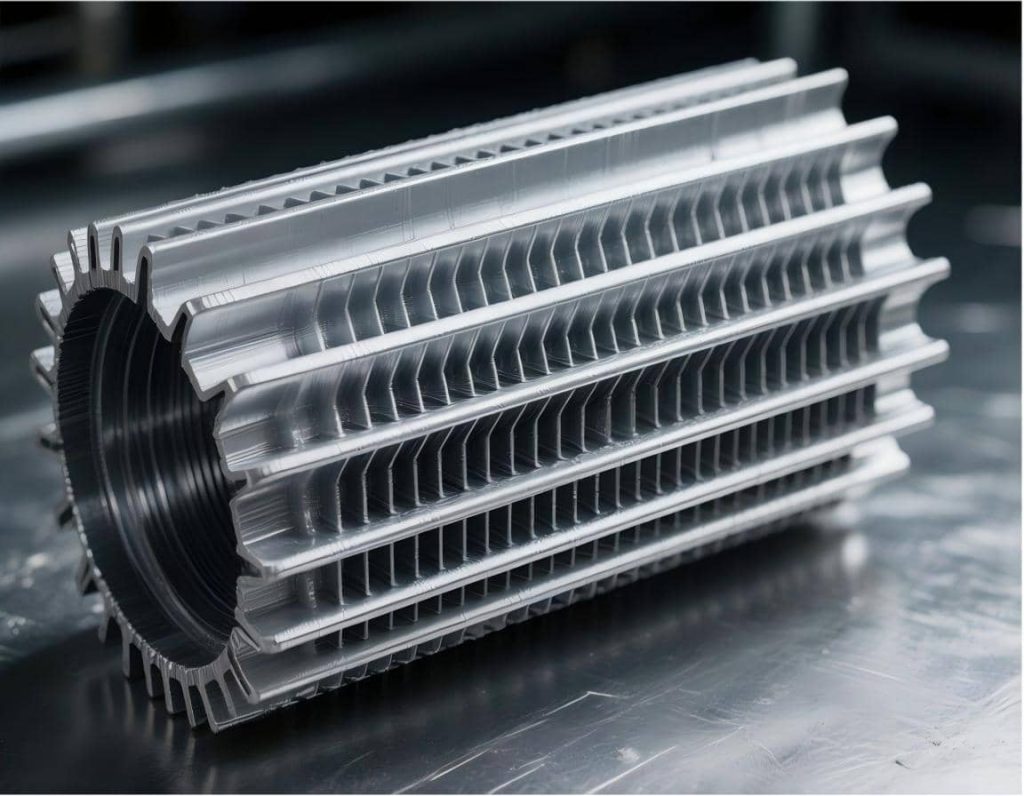

10. Is a Thinner Wall Always Better for Heat Dissipation?

In simple heat transfer applications, a thinner wall is, for the most part, better, as it has a lower thermal resistance. However, this is only part of the story. Overall heat transfer is also a function of the surface area and the alloy’s thermal conductivity. In some instances, an unreasonably thin-walled aluminum tube lacks the structural integrity needed to support the heat source or is more prone to denting.

The most reasonable course of action involves a compromise between the optimal thermal characteristics and the minimum acceptable structural robustness.

Processing and Applications

11. What are the wall thickness requirements for tube bending?

When bending a tube, the wall thickness is of great importance. If the wall is too thin for the tube’s diameter, the tube may collapse or wrinkle, particularly at the inner radius and during bending. To minimize the chance of this occurring, minimum wall thickness requirements are set for bending the tube. This may be the reason why some specialized suppliers of thin-wall aluminum tubing give instructions regarding the “D of bend” (the ratio of the bend radius to the tube diameter). As a general rule, a tube’s wall thickness should be greater than or equal to 10% of its outer diameter (OD). In the case of a 30 mm OD tube, for reliable bending, the wall should be at least 3 mm thick.

12. What should be considered when welding thin-wall aluminum tubing?

When welding thin-wall aluminum tubing, special attention must be paid to the tubing’s heat control to avoid burn-through.

When welding a thick-walled aluminum tube, preheating may be necessary to avoid cracking.

Welding technique should always be appropriate to the thickness of the material.

13. How does surface treatment, like anodizing, affect wall thickness?

Anodizing is an electrolytic process that forms a tough, corrosion-resistant oxidized layer on an aluminum surface. Although this process adds a trivial thickness, it is negligible (a few micrometers) and does not present a problem on a tube’s overall dimensions. Though for precision-fit applications, this is certainly worth mentioning.

14. What parameters (structural, fluid transport, decorative) guide the determination of wall thickness in my applications?

- Structural Components: Aluminum wall tubes of considerable thickness are needed in the construction of robust scaffolds to confer appropriate strength and rigidity. Also, think of a car chassis.

- Fluid Transport: Thickness is determined by the transport line pressure rating. Heavy-wall aluminium tubes are used for high-pressure hydraulic lines. For low-pressure fluid lines, a thin-walled tube is adequate.

- Decorative/Architectural: The emphasis in this case is on the value of aesthetics and on the ratio of structural weight to structural cost and structural cost. Structural elements such as thin-wall aluminum tubes are preferred to reduce the cost of construction.

- Heat Exchangers: Tubes with thin aluminum walls are preferred to enhance the thermal transfer efficiency.

Procurement and Quality Control

15. What is the best technique for measuring the thickness of aluminum tube walls?

To determine the best technique for estimating the thickness of aluminum wall tubes, one must compare digital micrometers and ultrasonic thickness gauges. While the digital micrometer provides a precise measurement, the ultrasonic gauge is advantageous in measuring the wall thickness from one side as it checks the consistency of a tubular section for the gauge length. Micrometer measurements must be complemented with at least one other technique. The additional technique must establish the uniformity of the tube by measuring several points along the tube axis, in the transverse direction, and in the circumferential direction.

16. How can I avoid the ‘negative tolerance’ trap when purchasing?

Some shady suppliers may abuse vague purchase orders and ship tubes that exactly meet the lower limit or even skip the lower limit of the specified range. To avoid this occurrence, always include a definite tolerance with both a positive and a negative range (e.g., Nominal thickness 0.125″ ±0.005″). If the application permits, you may specify only a positive tolerance, such as +0.005″/-0.000″, but that will raise the price.

17. What are the costs and lead times for custom non-standard wall thicknesses?

The costs and lead times for custom wall thicknesses substantially differ from those for standard sizes, as those would require custom tooling or a dedicated run for your order. The procurement department should consider that in relation to the needs of the project.

18. Aside from wall thickness, what other important quality documents should I look for when making a purchase?

Always ask for MTR. This document details the tube’s chemical composition and mechanical properties and confirms whether it falls under the specified alloy and temper. Also, look for a Certificate of Conformance (CoC), which confirms that the product was made in adherence to the standards set. These documents ensure traceability and act as a protection from non-conforming materials and provide compliance documents.

19. Out of the numerous options I have, how can I identify the best quality supplier?

Identify suppliers who have established a track record. Verify their accolades (e.g. ISO 9001 certification), their quality control systems, and request customer referrals. The best suppliers, and those who supply the best quality thin wall aluminum tubing, are open regarding their manufacturing methods and furnish extensive technical assistance. Suppliers with offers that are priced suspiciously low are likely to compromise quality. For your supply of aluminum tubing, do not hesitate to contact CHAL, as it reliable supplier.

20. What is the fundamental philosophy concerning the purchase of aluminum tubes?

The fundamental philosophy is to achieve the right amount of balance with respect to performance, cost, and risk. First, do not specify the wall thickness to be excessively large, as that would lead to added costs and excessive weight. On the flip side, do not specify the wall thickness to be excessively low, as that may cause failure of the product. A successfully executed purchase is one in which the buyer successfully determines the minimal requirements of the application and then of the tube, which should be accepted as meeting the requirements consistently with high accuracy. Learning and applying the principles in this guide will help you make smart, cost-efficient decisions.