In a future filled with tech, one can picture a vivid landscape of interwoven advanced solar panels following the sun, electric cars cruising smoothly on the busy highways, and oversized, whispering containerized batteries sitting in harmony with other lined batteries on the network. This is the new energy revolution, which envisions a monumental shift towards decarbonization. While some focus on the power electronics and advanced computing of smart grids, the race is on towards a greener tomorrow, which often overlooks the technology foundation that everything is built upon—the lightweight, strong, and durable physical structures.

A lightweighting champion and structural master, the 6061 T6 rectangular tube is an “invisible hero”. This master of structural mechanics has superb workability, excellent corrosion resistance, and a high strength to weight ratio. In this article, I will go through how this material, which appears ordinary on the surface, has become an important driving force that facilitates the advancement of numerous green technology sectors and propels the world toward a low-carbon, sustainable future.

Chapter 1: Why 6061 T6 Aluminum Rectangular Tubing?

Choosing a material to enclose sensitive systems in a solar farm or an EV battery pack is indeed a penetrating problem to be analyzed in terms of cost, value, and lifecycle; however, the solution often lies in the 6061 T6 alloy.

The superior performance of 6061 T6

Aluminum 6061 T6 is a marketed alloy very often used in manufacturing. The T6 indicates that the alloy has been solution and age hardened, which artificially boosts the alloy’s stiffness and applies to welded components, shaving almost 40% of the weight, ultimately serving a competition, which translates to lower expenses.

Additionally, this alloy has a very high level of resilience to weathering over the years. The raw armor Al can be passivated to an AlO rod, which is a thin, dense protective ceramic against the voracious UV rays, torrential rain, or salt fog, which is very handy when describing its life expectancy. Lastly, an element that is not lost in performance and is very easy to attain in a steady-state economy.

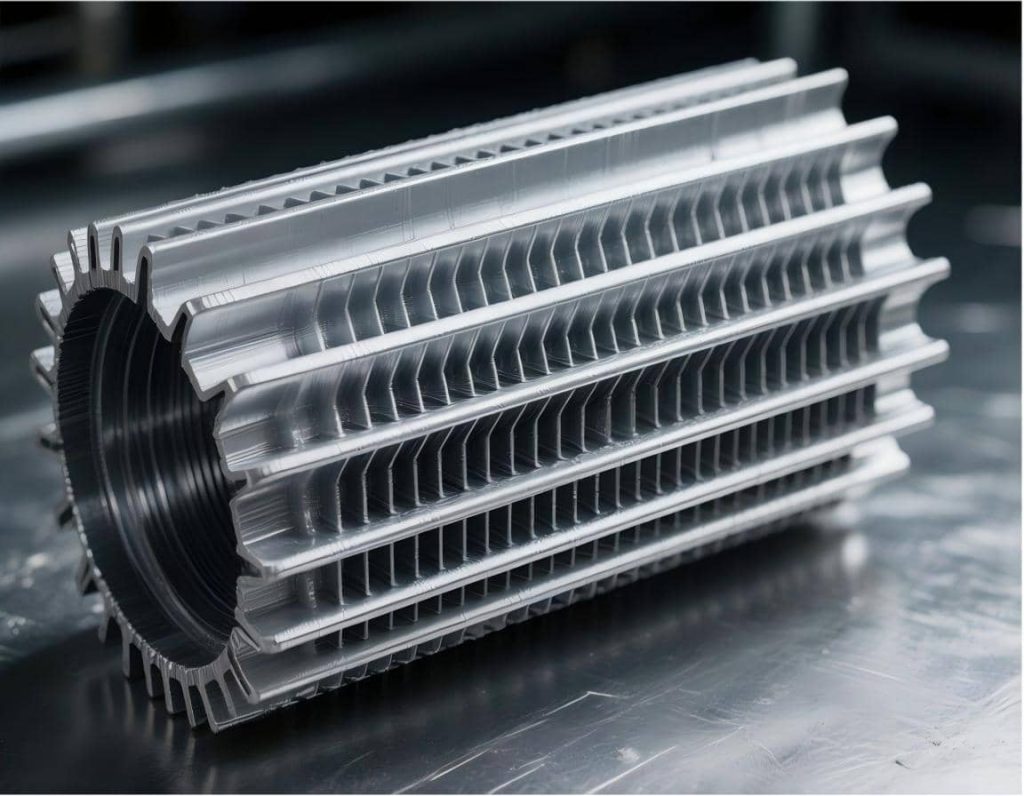

Structural Magic of Rectangular Tubing

Unlike other forms, such as pipes, aluminum rectangular tubing has unique shape advantages. Its rectangular cross-section has loads of stiffness, bending along vertical and lateral loads pretty common in support structures. Less material needed for the same load increases structural efficiency, supporting lightweighting and cost reduction. The flat surfaces also enhance design flexibility for easy connection and installation. These surfaces easily mate with other components, such as photovoltaic glass or battery modules, thus simplifying system assembly.

Chapter 2: The Structural Backbone of PV Power Plants

6061 T6 rectangular tubing is essential in generating solar energy because it provides the framework needed to capture the sun’s energy.

The Dual Benefits of Low Weight and High Strength

The photoelectric PV systems racked cross-beams, purlins, and posts utilize the tubing in considerable amounts. Its greatest worth is that it can reduce the support structure’s weight while maintaining enough stability to support the load of a roof-mounted or ground-mounted commercial foundation. Using such a mechanism saves material and installation costs, while still enabling the structure to withstand extreme wind and heavy snowfall.

The 25 Year Promise of Durability

Utility scale PV power plants can be expected to function for 25 years, or even longer, without hiccups. Durability of every component is a common expectation. The 6061 T6 rectangular tube alloy has excellent corrosion resistance. Hence, the alloy tube will meet this expectation. The support system ensures the operation is dependable and consistent while safeguarding the station. The costs also remain favorable, with little maintenance required. This is a strong long-term ROI for the power station.

Chapter 3: The Lightweighting Code of New Energy Vehicles

To increase the range capabilities and performance of EVs, mass reduction is and will always be a focal point. Hence, the importance of aluminium.

Structural Reinforcement for Body and Chassis

In performance-driven scenarios such as racing EVs or the chassis of commercial vehicles, Aluminium rectangular tubing is indispensable for structural reinforcement of, but not limited to, body frames and roll cages. It provides ultra high structural rigidity to a confined space, thus enhancing the handling, responsiveness, and passenger safety during a collision of the EV.

The Battery Pack Guardian

One of the most important applications is at the heart of the EV battery pack. The 6061 T6 rectangular tube is commonly used for the internal cross-members, longitudinal beams, and external framing of the battery enclosure.

To begin with, it acts as a safety barrier, providing strong mechanical protection to vulnerable battery cells from impact, puncture, and crushing forces. Also, its contribution to lightweighting is direct and measurable; removing battery enclosure mass, specifically unsprung mass, equals greater driving range and suspension performance. Last, due to aluminum’s good thermal conductivity, the battery pack frame can also assist in thermal management, working with the cooling system to dissipate heat and maintain optimal cell operating temperatures for performance and lifecycle longevity.

Chapter 4: The Support Framework for ESS and Hydrogen

The new energy ecosystem now includes energy storage and other sophisticated fuel technologies besides generation and mobility.

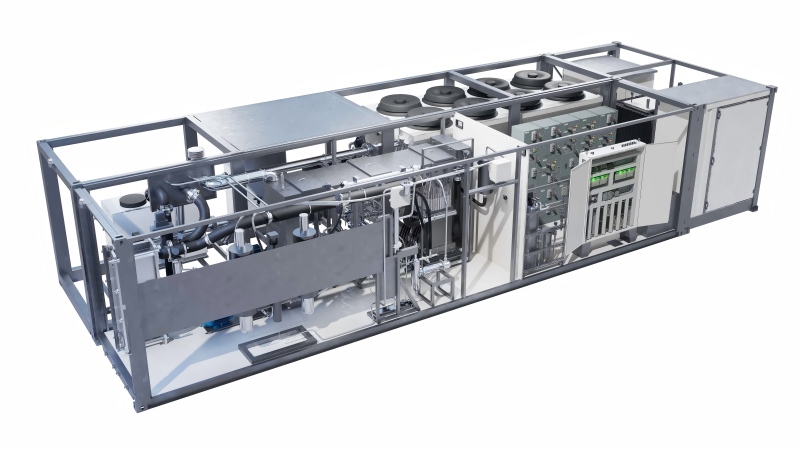

The Robust Skeleton of Energy Storage Cabinets

Containerized Battery Energy Storage Systems (BESS) are crucial to Battery Energy Storage Systems’ stability. These systems incorporate thousands of batteries, an array of power conversion systems (PCS), and complex wiring. For high-weight storage cabinets, the primary load-bearing system is the 6061 T6 rectangular tube. Its rigidity guarantees the structural stability and safety of the system during/after stressful operations like hard lifting, transportation, and during continuous operations. Its structural rigidity, lightweight nature, and high-impact corrosion resistance make it the ideal candidate to support structures like crane lifting and operate in dynamic and stressed environments, ranging from desert dry, tough climate, to coastal.

Precision Frameworks for Hydrogen Equipment

The latest trends in the hydrogen economy drive the need of BESS advanced, corrosive, and insecure BESS components for key equipment. The aluminum rectangular tubing is effective for non-magnetic and corrosion-resistant framework, aiding support to precision components in systems that require high levels of hygiene and structural integrity, like electrolyzers, fuel cell internal support structures, and hydrogen refueling station equipment.

Chapter 5: Summary and Looking Ahead

Aluminium 6061 T6 may be used for many things such as a structural frame for a wind part, but its energyst was was was were, and still is, of great importance to the new energy revolution of the circular economy and the closed loop “production, use, recycling and remanufacture” of the Cloud of Closed. It is remanufactured many times and is undiminished in quality, which aligns with the core tenet of devastatingly green and sustainable technology and reeks of a sustainable ethos. It is used as an example of the circular economy.

It is probable that in the future, new energy technologies will require highly complex structural efficiency. This rectangle, the 6061 T6 tube, will also advance and will be used in conjunction with novel methods of fusion welding. Advanced injectable surface treatments will also be used with strengthened adhesive bonds and other surface methods. This will be used for new integrations that need ultra high strength, complex.

To summarise, the advancement of green technology is always going to be the core 6061 T6 rectangular tube is bonded deep within the supply chain of it. Green technology is going to always be the structural element used to enable the technical functions. This is a CGT technology that has low weight, high strength, and low weight with the ability to be recycled and close down emissions in the future.