At the moment, the global Heating, Ventilation, Air-Conditioning, and Refrigeration (HVAC-R) industry is undergoing radical changes. It accredits the effective policies that foster environmental conservation, the arising necessity for foreign regulations, which is leading to the elimination of high-GWP (Global Warming Potential) refrigerants, and the integration efficiency. Application of aluminum microchannel tubes at the core of this shift demonstrates a journey from a tube applied typically in radiator vehicles to one of the most dominant technologies in the HVAC industry, which remains very stationary and is great for use in this field.

What is an Aluminum Microchannel Tube?

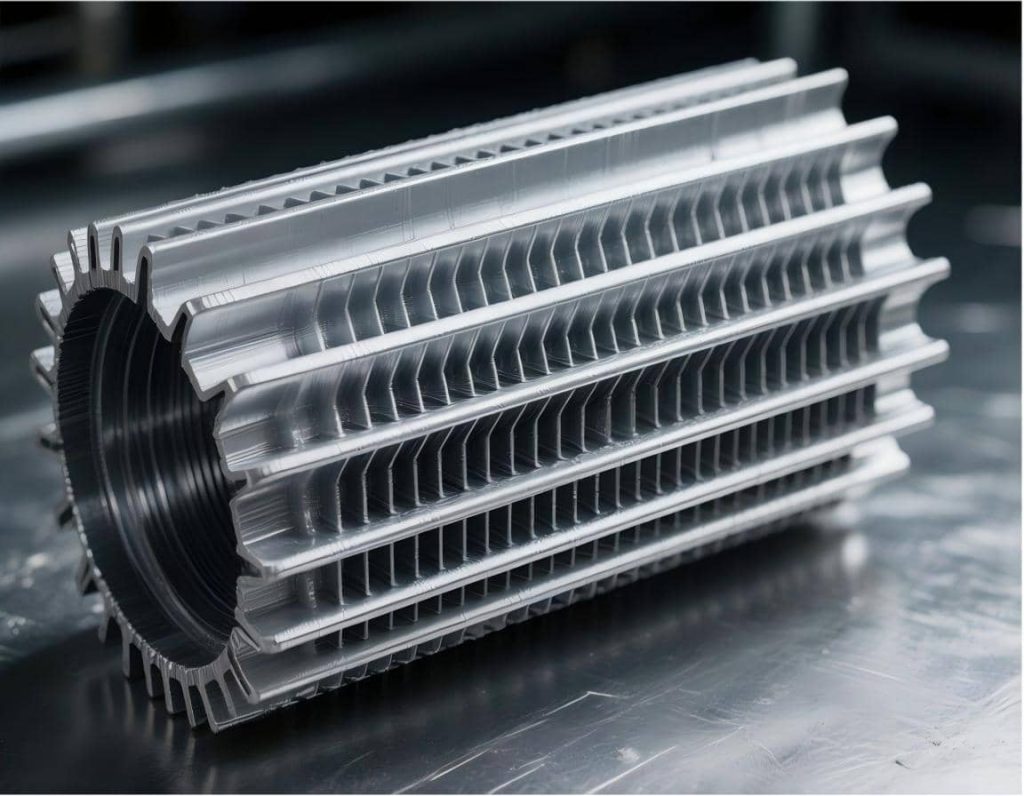

An aluminum microchannel tube is a highly engineered, flat, and rectangular extruded tube that contains several small, parallel channels (ports). These ports allow refrigerant to flow through a significantly larger internal surface area compared to a single large round tube.

Mostly manufactured from high-purity aluminum alloys, including the 3000 and 1000 series, these tubes are usually developed with cracks that are sealed using a thin zinc or flux layer. The coating prevents oxidation and aids in brazing. The structure of such a part, duly designed with such an accomplishment, is lighter than copper and constructs and is frightfully easy to construct.

Why Aluminum Microchannel Tubes are Dominating the HVAC Sector?

The change from copper tube-and-fin coils to all-aluminum microchannel coils is more of a need than a requirement. Various components guarantee the compatibility between the material and system design:

1. Superior Heat Transfer Efficiency

The hydraulic diameter of the ports in an aluminum microchannel tube is significantly smaller than that of standard tubing. This creates a higher heat transfer coefficient. Because the tubes are flat, they offer a larger primary surface area for air-to-refrigerant heat exchange. This allows for a more compact unit that delivers the same, or better, cooling capacity than a much larger traditional system.

2. Drastic Refrigerant Charge Reduction

One of the biggest benefits of an aluminum microchannel tube for HVAC applications is the reduced internal volume enhancement brought by using it. Normally, microchannel coils need 30%-45% less refrigerant to run compared to the conventional copper/aluminum coils. The total charge must be ideally limited especially with the cost of gas being what it is and the fact that more systems are adopting natural refrigerants like R290 and the low-GWP refrigerant blends.

3. Weight Reduction and Material Stability

Aluminum is around two-thirds the weight of copper. After all, by replacing copper coils with aluminum, as in microchannel designs, it is possible to reduce the weight of the outdoor condenser by 50%. Also, in the area of price risks in copper, which are quite significant in the current situation, the stability of aluminum costs allows for a better financial approach to the equipment installation.

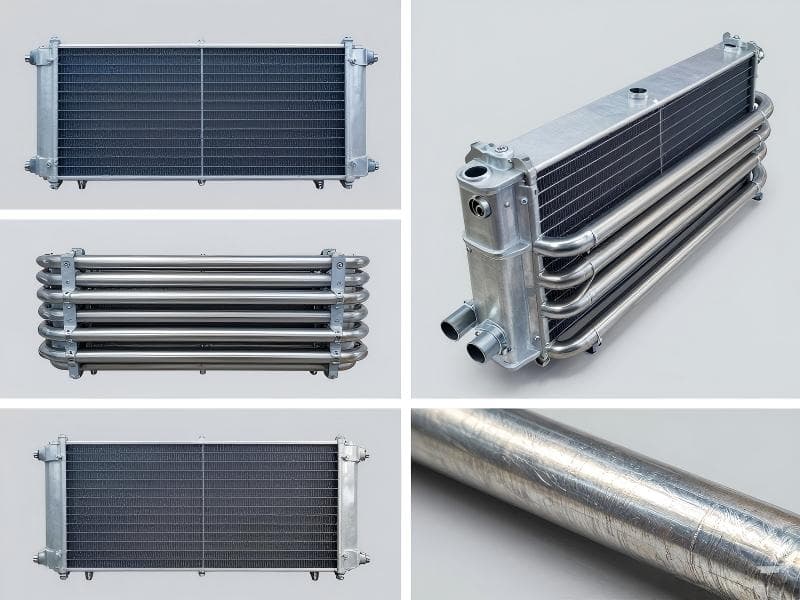

Maximizing Performance: The Aluminum Microchannel Tube Condenser

The most common application for this technology is in the aluminum microchannel tube condenser. In a traditional condenser, different metals (copper tubes and aluminum fins) are used together. This “bi-metal” construction is susceptible to galvanic corrosion and creates thermal resistance at the point where the tube meets the fin.

1. The All-Aluminum Benefit

In an aluminum microchannel tube condenser, the tubes, fins, and manifolds are all made of aluminum. This creates a “monometallic” system.

- Galvanic Corrosion Resistance: Since there are no dissimilar metals, the electrochemical reaction that leads to corrosion is virtually eliminated.

- Metallurgical Bonding: Metallurgical Bonding: Through a procedure known as Controlled Atmosphere Brazing (CAB), the fins are bonded to the tubes. This allows for ideal heat transfer in that heat passes from the tube to the fin easily and with minimal resistance.

2. Durability in Harsh Environments

Special coverings of the microchannel condensator (for example, e-coat or special diffusion Zn coatings) have become extremely popular in modern building applications and factories near the sea, where the salt in the wind and any industrial pollution would corrode a traditional copper–aluminium system within a few years.

Technical Specifications and Advanced Manufacturing

The typical working conditions of the aluminum microchannel tube could be shaped by its structure and the type of composition used. Most manufacturers primarily concentrate on high-purity aluminum alloys in the 3003 or 3102 series, which are malleable and are resistant to corrosion.

| Features | Specification Range |

| Material | 1000, 3000, or 6000 Series Aluminum Alloys |

| Coating Options | Zinc Spray, Flux Coating, or Hydrophilic Coating |

| Port Geometry | Circular, Square, or Rectangular Ports |

| Width | Typically 12mm to 32mm+ |

| Applications | Condensers, Evaporators, Radiators, Oil Coolers |

To further enhance durability, many tubes receive a zinc diffusion layer or specialized epoxy coatings. This is particularly vital for HVAC systems installed in coastal regions where salt spray can lead to “pitting” corrosion. Modern manufacturing also allows for “folded” or “corrugated” fins to be brazed directly to the flat surface of the tubes, creating a seamless thermal path.

Sustainability and the Circular Economy

There is a growing need for the HVAC sector to produce plants with low carbon production. Aluminum microchannel tubes are a perfect choice for this with 2 reasons:

- Operational Efficiency: Higher heat transfer means the compressor works less, leading to lower electricity consumption over the life of the unit.

- Ease of Recycling: Traditional coils are a mix of copper and aluminum, making the separation complex and very high in energy. An all-aluminum microchannel coil broker is 100% recyclable as a single-material stream, and this encourages a circular economy and reduces the environmental damage from end-of-life systems.

Maintenance: Best Practices for Longevity

While aluminum microchannel tubes are robust, they require specific maintenance protocols to ensure peak performance.

- Cleaning: Because the fins are densely packed, it is important to use low-pressure water and pH-neutral cleaners. High-pressure washers can bend the delicate fins and trap debris.

- Visual Inspection: Regularly checking for “white powder” (aluminum oxide) can help identify early signs of environmental stress, allowing for protective treatments before a leak occurs.

Custom Solutions for Your HVAC Needs

Would you like to improve the performance of your HVAC setup using microchannel technology? Contact us today, and we are ready to provide you with proprietary MPE tubing designs for various pressure and temperature requirements.