Microchannel aluminum flat tubes, often referred to as parallel flow aluminum flat tubes, represent a breakthrough in heat exchanger technology. These thin-walled, porous, flat-shaped tubes exhibit exceptional thermal conductivity and impressive corrosion resistance. Their unique properties make them a versatile material extensively utilized in a variety of systems, including automotive, air conditioning, refrigeration, and electronic equipment. In this article, we will delve into the structure, characteristics, and the diverse range of applications of microchannel aluminum flat tubes, exploring how they are transforming the way we approach heat exchange in various industries.

Structure and Characteristics of Microchannel Aluminum Flat Tubes

Internal Composition

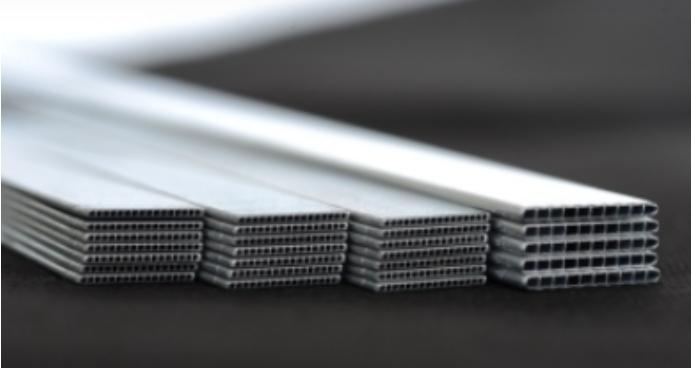

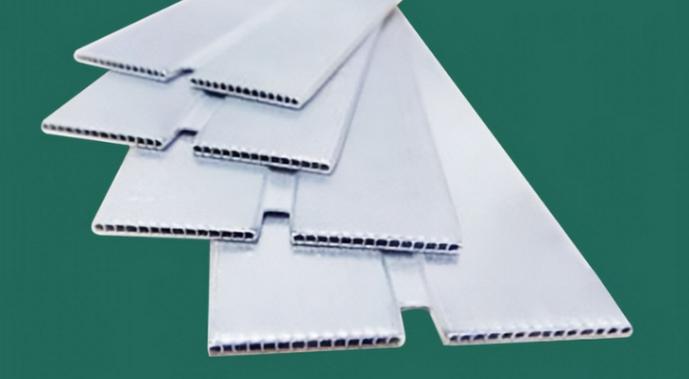

The internal microchannel aluminum flat tube is composed of multiple microchannels, which have various shapes, such as rectangular, triangular, and circular. The width of the channels is usually less than 0.5mm. The microchannels are arranged in a parallel or serpentine pattern, which maximizes the surface area for heat transfer.

Enhanced Corrosion Resistance

The internal microchannel aluminum flat tube is treated with a special process to form a uniform alumina protective layer, which improves the corrosion resistance. The alumina layer is also very thin, which helps to maintain the high thermal conductivity of the tube.

Thin Wall Thickness

The wall thickness of microchannel aluminum flat tubes is generally below 0.2mm, which is much thinner than traditional copper tubes and aluminum tubes. This thin wall thickness allows for rapid heat transfer between the fluid inside the tube and the fluid outside the tube.

Advantages of Microchannel Aluminum Flat Tube

Microchannel aluminum flat tube has a number of advantages over traditional copper tubes and aluminum tubes used in heat exchangers. These advantages include:

- Higher thermal conductivity: Microchannel aluminum flat tube has a thermal conductivity of about 230 W/m·K, which is significantly higher than that of copper (400 W/m·K) and aluminum (237 W/m·K). This means that microchannel aluminum flat tubes can transfer heat more efficiently, resulting in better cooling or heating performance.

- Lighter weight: Microchannel aluminum flat tube is about 30% lighter than copper tubes and 10% lighter than aluminum tubes of the same size. This can help to reduce the weight of heat exchangers and other systems that use them.

- Better corrosion resistance: Microchannel aluminum flat tube is typically coated with a protective layer of alumina, which gives it excellent corrosion resistance. This makes it suitable for use in harsh environments, such as those found in automotive and industrial applications.

- Smaller size: Microchannel aluminum flat tubes can be made much smaller than copper tubes and aluminum tubes, which can help to save space.

Applications of Microchannel Aluminum Flat Tube

Automotive

Microchannel aluminum flat tubes have found extensive applications in the automotive industry, particularly in the evaporators and condensers of automotive air conditioning systems. Compared to traditional copper and aluminum tubes, microchannel aluminum flat tubes offer superior thermal conductivity, resulting in faster and more effective cooling. Additionally, they contribute to the reduction of system weight and space requirements, a crucial consideration in the design of modern vehicles.

Air Conditioning

In the air conditioning sector, microchannel aluminum flat tubes are commonly employed in the evaporators and condensers of these systems. When contrasted with conventional copper and aluminum tubes, they enhance heat exchange efficiency, resulting in reduced energy consumption and operational costs. These benefits make them an ideal choice for energy-efficient HVAC systems.

Refrigeration

Microchannel aluminum flat tubes have been integrated into the condensers and evaporators of refrigeration systems, including refrigerators. Their implementation has led to improved cooling efficiency, decreased energy consumption, and quieter operation. Furthermore, these tubes have enabled the design of more compact and lightweight refrigerators, aligning with the demand for space-saving solutions in modern living spaces.

Electronic Equipment

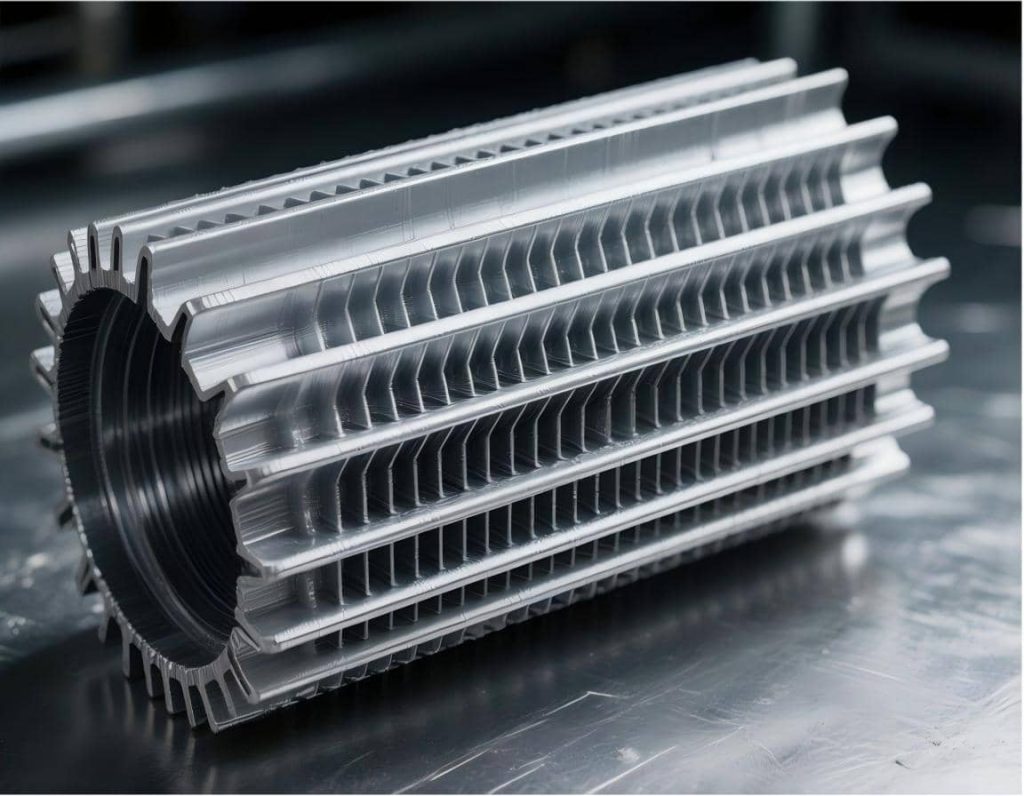

Microchannel aluminum flat tubes have emerged as a preferred option for heat sinks in electronic equipment. In comparison to traditional copper and aluminum tubes, they offer superior heat dissipation efficiency. This results in lower temperature increases within the electronic devices, ultimately extending their operational lifespan. In an era of ever-increasing demands on electronic equipment performance, microchannel aluminum flat tubes play a pivotal role in maintaining optimal operating conditions.

Conclusion

Microchannel aluminum flat tubes represent a promising advancement in heat exchanger materials, offering a wide array of benefits in terms of high thermal conductivity, robust corrosion resistance, and lightweight design. Their impressive performance in various applications, including the automotive, air conditioning, refrigeration, and electronic equipment sectors, highlights their significance in modern industries. As technology and energy efficiency become increasingly important, the role of microchannel aluminum flat tubes in enhancing heat exchange processes cannot be overstated. These innovative tubes are poised to drive further advancements in thermal management and energy conservation, making them a cornerstone of contemporary heat exchanger solutions.