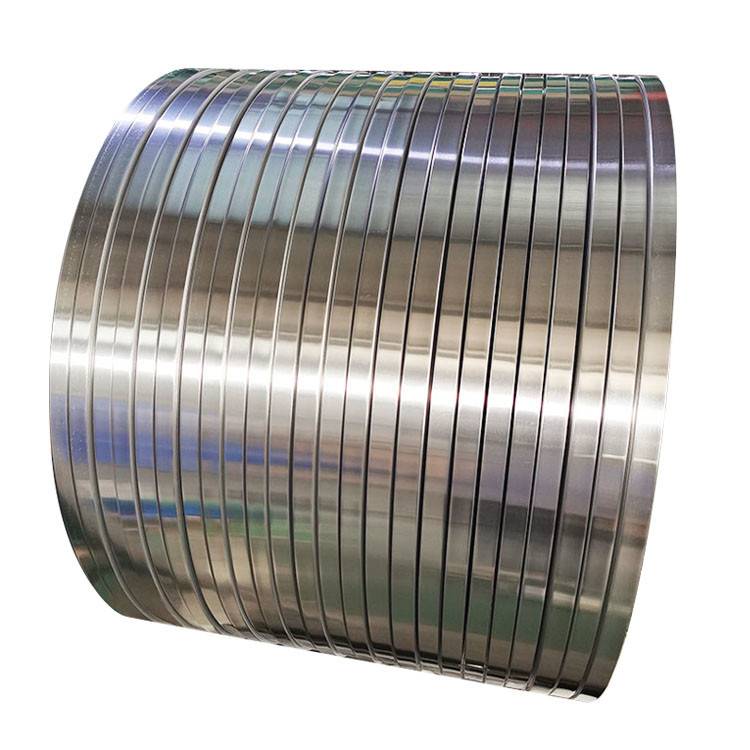

Aluminum strip is a versatile material with a wide range of properties. It is lightweight, corrosion-resistant, easy to form, and has good electrical and thermal conductivity. These properties make it a good choice for a variety of applications, including packaging, building materials, electrical components, and machinery. In this article, we will discuss the physical, mechanical, electrical, and thermal properties of aluminum strips.

Physical Properties of Aluminum Strip

The physical properties of aluminum strip are determined by the composition of the aluminum alloy and the rolling process used to create the strip. Some of the most important physical properties of aluminum strip include:

- Lightweight: Aluminum is very lightweight, with a density of only 2.7 g/cm3. This makes it a good choice for applications where weight is a concern, such as in the manufacture of beverage cans and other lightweight containers.

- Corrosion resistance: Aluminum is resistant to corrosion, making it a good choice for applications where it will be exposed to the elements. This is due to the formation of a thin, protective oxide layer on the surface of the aluminum.

- Formability: Aluminum is easy to form, making it a good choice for applications where complex shapes are required. This is because aluminum has a relatively high ductility, which means that it can be stretched and bent without breaking.

- Strength: Aluminum is strong enough for many applications, but it is also relatively soft, making it easy to work with. This makes it a good choice for applications where both strength and formability are important, such as in the manufacture of automotive parts and machinery.

Mechanical Properties of Aluminum Strip

The mechanical properties of aluminum strip are also important for determining its suitability for different applications. Some of the most important mechanical properties of aluminum strip include:

- Young’s modulus: Young’s modulus is a measure of the stiffness of a material. The higher the Young’s modulus, the stiffer the material. The Young’s modulus of aluminum strip is typically around 70 GPa.

- Shear modulus: Shear modulus is a measure of the resistance of a material to shearing forces. The higher the shear modulus, the more resistant the material is to shearing forces. The shear modulus of aluminum strip is typically around 25 GPa.

- Poisson’s ratio: Poisson’s ratio is a measure of the tendency of a material to expand in one direction when it is compressed in another direction. The Poisson’s ratio of aluminum strip is typically around 0.33.

Electrical Properties of Aluminum Strip

Aluminum strip is a good conductor of electricity, with a conductivity that is about 60% of that of copper. This makes it a good choice for applications where electrical conductivity is important, such as in the manufacture of electrical conductors and components.

Thermal Properties of Aluminum Strip

Aluminum strip is also a good conductor of heat, with a thermal conductivity that is about 50% of that of copper. This makes it a good choice for applications where thermal conductivity is important, such as in the manufacture of heat sinks and other thermal management devices.

Other Properties of Aluminum Strip

In addition to the physical and mechanical properties mentioned above, aluminum strip also has a number of other properties that make it a desirable material. These properties include:

- Density: The density of aluminum strip is 2.7 g/cm3. This is much lower than the density of other metals, such as steel (7.8 g/cm3) and copper (8.9 g/cm3). This makes aluminum strip a good choice for applications where weight is a concern.

- Melting point: The melting point of aluminum strip is 660 °C. This is relatively low compared to other metals, such as steel (1538 °C) and copper (1085 °C). This makes aluminum strip a good choice for applications where high temperatures are involved.

- Boiling point: The boiling point of aluminum strip is 2467 °C. This is also relatively low compared to other metals. This makes aluminum strip a good choice for applications where high temperatures are involved.

Conclusion

Aluminum strip is a versatile material with a wide range of properties. It is lightweight, corrosion-resistant, easy to form, and has good electrical and thermal conductivity. These properties make it a good choice for a variety of applications, including packaging, building materials, electrical components, and machinery.

In addition to the properties mentioned above, aluminum strip is also a recyclable material. This means that it can be recycled and reused, which helps to reduce the environmental impact of its use.