6061 Aluminum Coil vs. 5052 Aluminum Coil: Choosing the Right Alloy for Your Application

Aluminum coils are versatile materials widely used in various industries, thanks to their exceptional properties and applications. Among the plethora of aluminum alloys available, two popular choices stand out: 6061 and…

Al-Al Composite Tubes: The Foundation of Modern Auto AC Systems

The automotive industry has seen a remarkable transformation over the years, driven by advancements in technology, materials, and design. One such innovation that has silently revolutionized modern automobiles is the…

How Long Does Food Last With Aluminum Foil Packing?

Aluminum foil is a versatile kitchen staple that has been used for decades to pack and preserve food. It is a thin, pliable metal sheet made from aluminum that is commonly…

Drawn Aluminum Tube vs. Inner Grooved Aluminum Tube: A Comprehensive Comparison

Aluminum tubes are a versatile and durable material with a wide range of applications. They are lightweight, strong, corrosion-resistant, and have excellent thermal conductivity and electrical conductivity. Aluminum tubes are available…

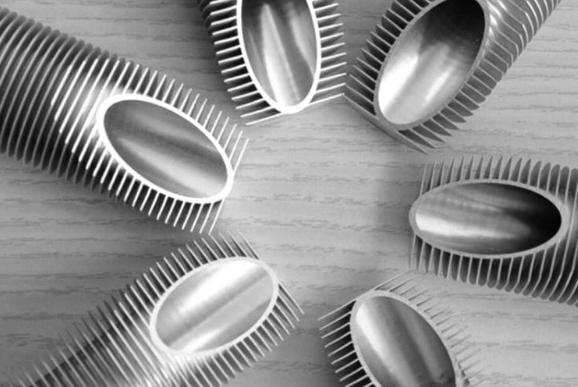

Aluminum, Copper, and Stainless Steel Finned Tube: Which is Right for You?

Heat exchangers are an integral part of various industrial processes and systems, playing a critical role in transferring heat from one fluid to another. Finned tubes, also known as finned…

Aluminum Strip in Sustainable Architecture: Green Building Materials

Sustainable architecture is on the rise, driven by a growing awareness of the environmental impact of construction and a desire to create buildings that are energy-efficient, environmentally friendly, and aesthetically…

Choosing the Right Aluminum Alloy: 3003 vs. 6061

Aluminum is a versatile material widely used in various industries for its lightweight, corrosion resistance, and excellent formability. When it comes to selecting the right aluminum alloy for a particular…

6061 T651 vs. 6061 T6 Aluminum Sheet: Which One Is Better for Your Precision Machining Needs?

6061 aluminum is one of the most versatile and widely used aluminum alloys. It is known for its good mechanical properties, machinability, weldability, and corrosion resistance. 6061 aluminum is available…

Top 5 Popular Different Types of Aluminium Doors and Their Advantages

When it comes to selecting doors for your home or commercial space, the choices are numerous, each offering its unique benefits. Among these options, aluminum doors have garnered considerable attention due…

Aluminum vs. Stainless Steel Cookware: Making the Right Choice for Your Kitchen

When it comes to equipping your kitchen with the best cookware, two materials often dominate the choices: aluminum and stainless steel. Each has its unique characteristics and advantages. In this…

Aluminum Extrusions: Strength, Versatility, and Fabrication

Aluminum extrusions have become a staple in various industries, thanks to their remarkable properties that make them an ideal choice for a wide range of applications. In this article, we’ll delve…

What are the Different Types of Aluminum Coil and Their Applications?

Aluminum coil is a sheet of aluminum that has been rolled into a coil. It is a versatile material that is used in a wide variety of applications. The different types…