Aluminum tubes are a versatile and durable material with a wide range of applications. They are lightweight, strong, corrosion-resistant, and have excellent thermal conductivity and electrical conductivity. Aluminum tubes are available in a variety of shapes, sizes, and specifications, making them ideal for a wide range of industries.

What Are Drawn Aluminum Tubes?

Drawn aluminum tubes are manufactured by drawing a billet of aluminum through a series of dies. This process reduces the diameter of the billet and increases its length. Drawn aluminum tubes can be produced with a wide range of wall thicknesses and diameters. They are typically seamless, meaning that they do not have a weld seam.

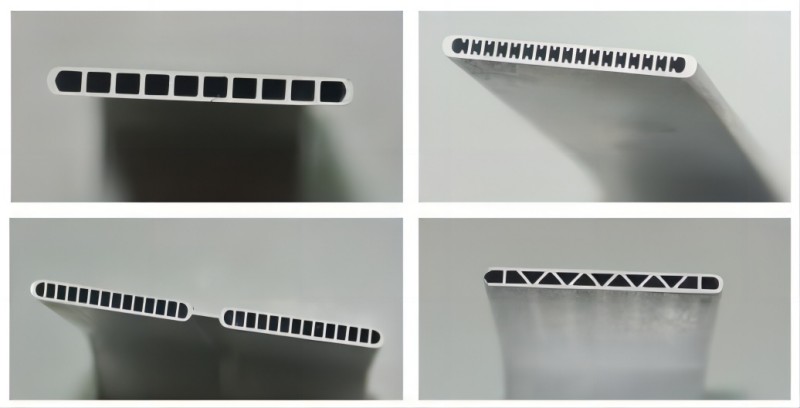

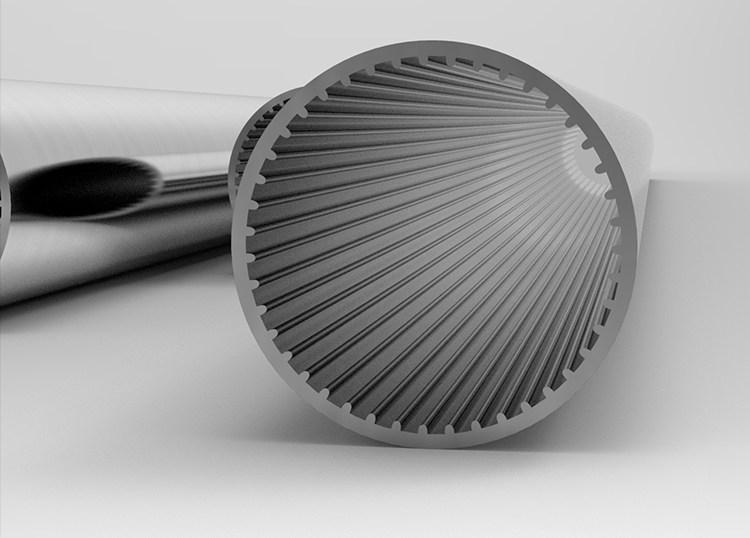

What Are Inner Grooved Aluminum Tubes?

Inner grooved aluminum tubes are drawn aluminum tubes that have been machined with grooves on the inner surface of the tube. These grooves can be straight, spiral, or have a more complex pattern. Inner grooved aluminum tubes are typically used in applications where enhanced heat transfer is required.

Comparison of Drawn Aluminum Tube and Inner Grooved Aluminum Tube

Manufacturing Process

Drawn aluminum tubes are manufactured by a relatively simple process. The billet of aluminum is first heated to soften it. It is then drawn through a series of dies, which reduce the diameter of the billet and increase its length. The tube is then annealed to relieve any residual stress.

Inner grooved aluminum tubes are manufactured in a similar manner to drawn aluminum tubes, with the additional step of machining the grooves on the inner surface of the tube. This machining can be done using a variety of methods, such as broaching, honing, or laser cutting.

Properties

Drawn aluminum tubes and inner grooved aluminum tubes have similar properties, with the exception of heat transfer. Inner grooved aluminum tubes have a higher heat transfer rate than drawn aluminum tubes due to the increased surface area of the inner grooves.

The following table compares the key properties of drawn aluminum tubes and inner grooved aluminum tubes:

| Property | Drawn Aluminum Tube | Inner Grooved Aluminum Tube |

| Manufacturing process | Simple | More complex |

| Heat transfer rate | Lower | Higher |

| Mechanical properties | Good | Good |

| Corrosion resistance | Good | Good |

| Thermal conductivity | Excellent | Excellent |

| Electrical conductivity | Excellent | Excellent |

| Machinability | Good | Good |

| Cost | Lower | Higher |

Applications of Drawn Aluminum Tube and Inner Grooved Aluminum Tube

Drawn aluminum tubes and inner grooved aluminum tubes are used in a wide variety of applications, depending on their unique properties.

Drawn Aluminum Tube Applications

- Heat exchangers: Drawn aluminum tubes are commonly used in heat exchangers, such as radiators, condensers, and evaporators. Their lightweight construction and excellent thermal conductivity make them ideal for these applications.

- Automotive components: Drawn aluminum tubes are used in a variety of automotive components, such as fuel lines, brake lines, and air conditioning coils. Their strength and durability make them well-suited for these demanding applications.

- Aerospace components: Drawn aluminum tubes are also used in a variety of aerospace components, such as aircraft frames and engine components. Their lightweight construction and high strength-to-weight ratio make them ideal for these applications.

- Electrical components: Drawn aluminum tubes are also used in a variety of electrical components, such as busbars and heat sinks. Their excellent electrical conductivity and thermal conductivity make them ideal for these applications.

- Food and beverage processing equipment: Drawn aluminum tubes are also used in a variety of food and beverage processing equipment, such as heat exchangers and mixers. Their corrosion resistance and easy cleanability make them ideal for these applications.

- Pharmaceutical equipment: Drawn aluminum tubes are also used in a variety of pharmaceutical equipment, such as heat exchangers and mixing vessels. Their corrosion resistance and easy to cleanability make them ideal for these applications.

- Chemical processing equipment: Drawn aluminum tubes are also used in a variety of chemical processing equipment, such as heat exchangers and reactors. Their corrosion resistance and ability to withstand high temperatures make them ideal for these applications.

Inner Grooved Aluminum Tube Applications

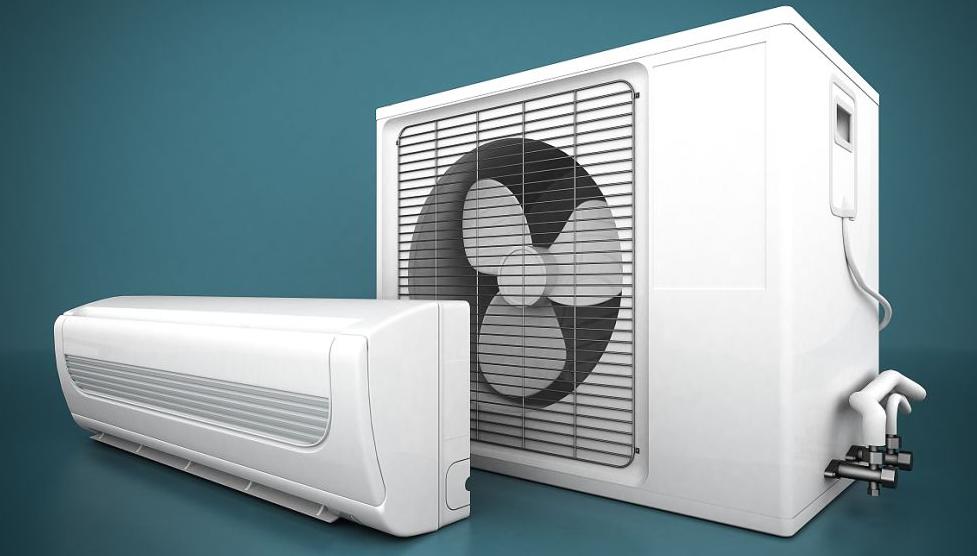

- Condensers: Inner grooved aluminum tubes are commonly used in condensers, such as those used in air conditioning and refrigeration systems. The grooves on the inner surface of the tubes increase the surface area, which improves heat transfer.

- Evaporators: Inner grooved aluminum tubes are also commonly used in evaporators, such as those used in air conditioning and refrigeration systems. The grooves on the inner surface of the tubes increase the surface area, which improves heat transfer.

- Oil coolers: Inner grooved aluminum tubes are also used in oil coolers, which are used to cool engine oil and transmission oil in vehicles. The grooves on the inner surface of the tubes increase the surface area, which improves heat transfer.

- Intercoolers: Inner grooved aluminum tubes are also used in intercoolers, which are used to cool compressed air in turbocharged and supercharged engines. The grooves on the inner surface of the tubes increase the surface area, which improves heat transfer.

- Heat sinks: Inner grooved aluminum tubes are also used in heat sinks, which are used to dissipate heat from electronic components. The grooves on the inner surface of the tubes increase the surface area, which improves heat transfer.

- Solar collectors: Inner grooved aluminum tubes are also used in solar collectors, which are used to absorb heat from the sun and convert it into thermal energy. The grooves on the inner surface of the tubes increase the surface area, which improves heat transfer.

- Electronics cooling systems: Inner grooved aluminum tubes are also used in electronics cooling systems, which are used to dissipate heat from electronic components in computers, servers, and other electronic devices. The grooves on the inner surface of the tubes increase the surface area, which improves heat transfer.

Conclusion

Drawn aluminum tubes and inner grooved aluminum tubes are both versatile and durable materials with a wide range of applications. Drawn aluminum tubes are typically used in applications where their low cost, lightweight construction, and good strength-to-weight ratio are important. Inner grooved aluminum tubes are typically used in applications where enhanced heat transfer is required.