The Second Life of Aluminum Sheet: Embracing the Sustainable Benefits of Recycled Aluminum

In a world increasingly aware of the environmental impact of human activities, the call for sustainable practices echoes across industries. One such innovation that stands out in the realm of…

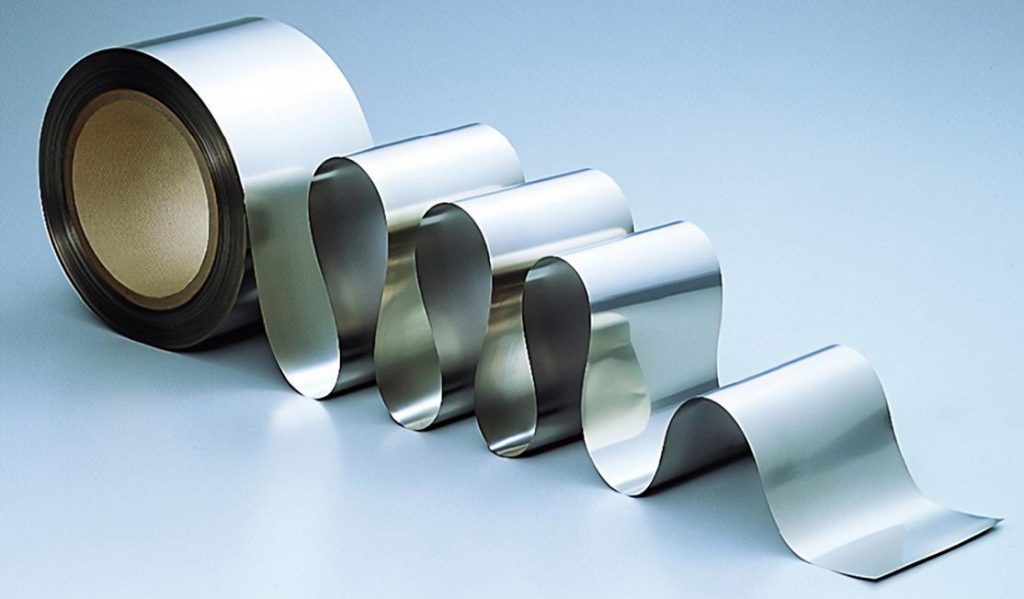

The Role of Aluminum Foil Packaging in Our Lives

In the whirlwind of modern life, the significance of aluminum foil packaging often goes unnoticed. Yet, this unassuming material, derived from thoroughly annealed aluminum, possesses a remarkable combination of properties that…

Aluminum Foil’s Hidden Talents: From Kitchen Staple to Multifaceted Marvel in Modern Applications

Upon exploring the practical and luxurious applications of aluminum foil, we uncover the soft and versatile side of this seemingly ordinary material. Aluminum foil, often associated with wrapping leftovers or…

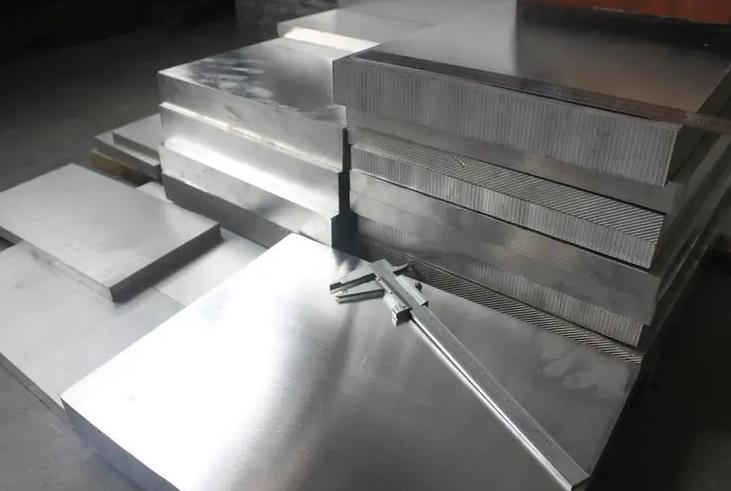

From Composition to Application: Decoding 1060 and 6061 Aluminum Sheet Differences

In the realm of metals, aluminum stands out for its lightweight, corrosion resistance, and malleability, making it a versatile material for diverse applications. Among the numerous alloys available, 1060 and…

Aluminum Die Casting for the Automotive Industry: Driving Innovation and Efficiency

The automotive industry is a dynamic landscape where innovation, performance, and efficiency are paramount. In recent years, aluminum die casting has emerged as a game-changer, revolutionizing the manufacturing processes within the…

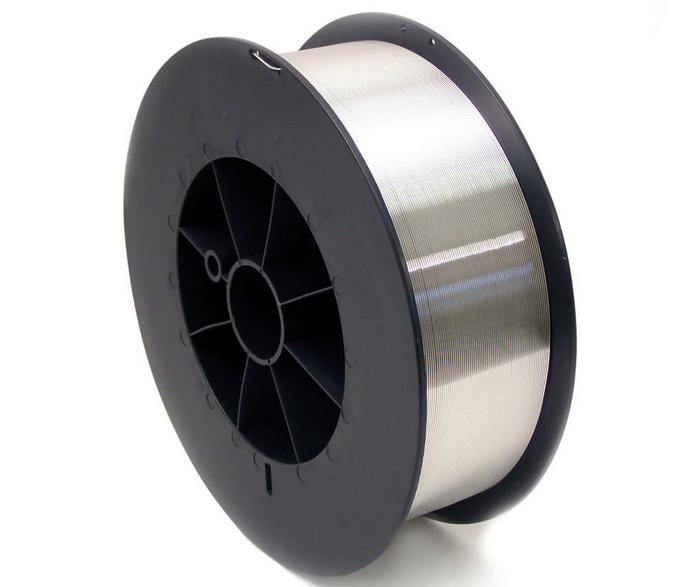

Navigating the World of Aluminum MIG Wire: Choosing the Right Wire for Your Needs

Aluminum MIG welding is a versatile and efficient method for joining aluminum components. This process utilizes a consumable electrode, known as aluminum MIG wire, to create a strong and durable…

The Role of Aluminum Wire Mesh in Automotive Applications

Aluminum wire mesh has become an integral component in the automotive industry, playing a crucial role in enhancing vehicle aesthetics, performance, and fuel efficiency. Its unique properties of lightweight, durability, and…

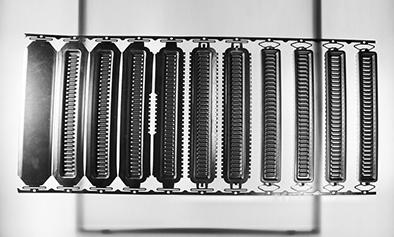

The Role of Aluminum Stamping Parts in Consumer Electronics

Consumer electronics have become an indispensable part of our daily lives, and behind the sleek and sophisticated designs of smartphones, laptops, and other gadgets lies a crucial element—aluminum stamping parts…

Aluminum Foil: A Versatile Material with Diverse Applications

Aluminum foil, a thin, lightweight, and flexible sheet of aluminum, has become an indispensable material in modern society. Its remarkable properties, including its ability to block light, heat, and moisture,…

Alumina Fiber: Unleashing the Power of High-Performance Material

Alumina fiber, also known as aluminum oxide fiber, is a high-performance inorganic fiber with exceptional properties that make it suitable for a wide range of applications. Its main component is…

Aluminum Battery Covers: A Comprehensive Review of Materials, Design, and Manufacturing

Batteries are the lifeblood of our modern, mobile society, powering everything from smartphones to electric vehicles. As the demand for more efficient and sustainable energy solutions grows, manufacturers are constantly…

Shaping Light, Shaping Design: The Versatility of Aluminum LED Casing

In the realm of contemporary design and technology, the marriage of form and function has never been more profound than in the realm of lighting. With the advent of LED…