Consumer electronics have become an indispensable part of our daily lives, and behind the sleek and sophisticated designs of smartphones, laptops, and other gadgets lies a crucial element—aluminum stamping parts. The marriage of technology and precision engineering in the consumer electronics industry relies heavily on the versatility and unique properties that aluminum stamping brings to the manufacturing process.

The Benefits of Aluminum Stamping Parts for Consumer Electronics

There are many benefits to using aluminum stamping parts in consumer electronics devices. These include:

- Weight reduction: Aluminum is a lightweight metal that can help to reduce the overall weight of consumer electronics devices. This is important for portable devices, such as smartphones and tablets, as it can improve battery life and make them easier to carry.

- Strength: Aluminum is a strong metal that can withstand the rigors of everyday use. This makes it an ideal material for parts that need to be durable, such as casings and connectors.

- Corrosion resistance: Aluminum is a corrosion-resistant metal that can withstand the elements. This is important for consumer electronics devices that may be exposed to moisture, such as outdoor speakers and headphones.

- Cost-effectiveness: Aluminum stamping is a cost-effective manufacturing process that can help to reduce the overall cost of consumer electronics devices. This is because aluminum is a relatively inexpensive material, and the stamping process is relatively simple.

- Design flexibility: Aluminum stamping is a versatile manufacturing process that can be used to create a wide variety of shapes and sizes of parts. This makes it an ideal material for the complex designs of many consumer electronics devices.

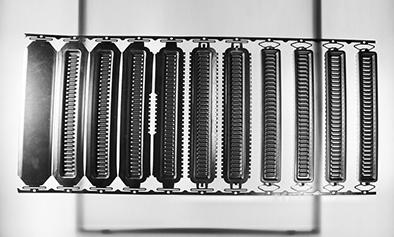

Applications of Aluminum Stamping Parts in Consumer Electronics

Aluminum stamping parts are used in a wide variety of consumer electronics devices. Some of the most common applications include:

- Casings: Aluminum casings are used to protect the internal components of consumer electronics devices. They are often made from lightweight, strong, and corrosion-resistant aluminum alloys.

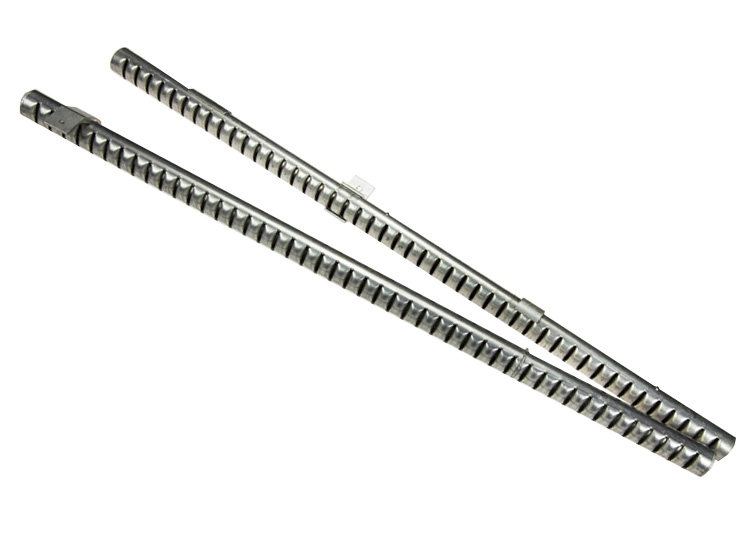

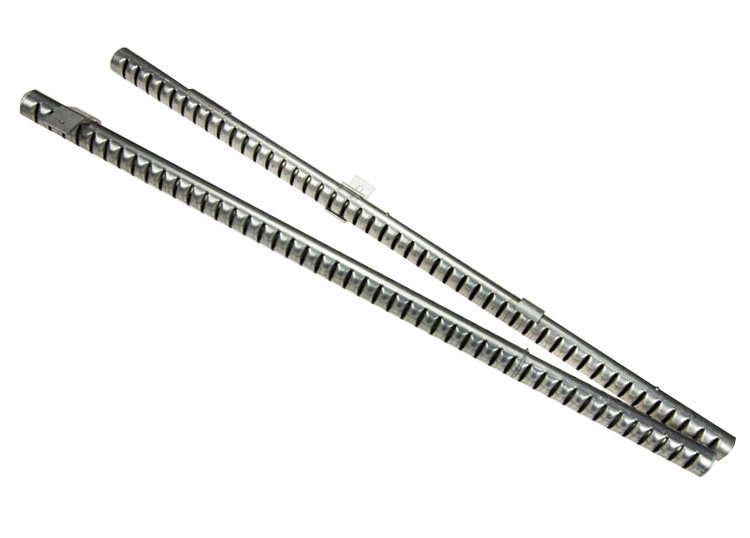

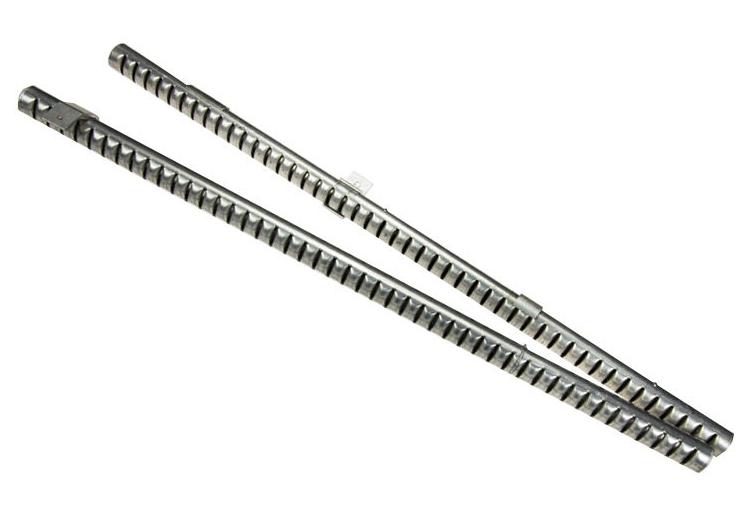

- Connectors: Aluminum connectors are used to connect the internal components of consumer electronics devices. They are often made from lightweight, conductive, and corrosion-resistant aluminum alloys.

- Antennas: Aluminum antennas are used to transmit and receive radio signals. They are often made from lightweight, conductive, and corrosion-resistant aluminum alloys.

- Heat sinks: Aluminum heat sinks are used to dissipate heat from consumer electronics devices. They are often made from lightweight, conductive, and corrosion-resistant aluminum alloys.

- Shields: Aluminum shields are used to protect the internal components of consumer electronics devices from electromagnetic interference (EMI). They are often made from lightweight, conductive, and corrosion-resistant aluminum alloys.

The Future of Aluminum Stamping Parts in Consumer Electronics

The demand for aluminum stamping parts is expected to continue to grow in the consumer electronics industry. This is due to the increasing demand for lightweight, strong, and corrosion-resistant materials. In addition, the development of new aluminum alloys with improved properties is also expected to drive demand.

As the demand for aluminum stamping parts in the consumer electronics industry grows, manufacturers are expected to invest in new technologies to improve the quality and efficiency of the stamping process. This is likely to lead to the development of new and innovative aluminum stamping parts that can meet the demanding requirements of consumer electronics devices.

Conclusion

Aluminum stamping parts play an important role in the consumer electronics industry. They offer a wide range of benefits, including weight reduction, strength, corrosion resistance, cost-effectiveness, and design flexibility. As the demand for consumer electronics devices continues to grow, the demand for aluminum stamping parts is also expected to increase. Manufacturers are expected to invest in new technologies to improve the quality and efficiency of the stamping process, which is likely to lead to the development of new and innovative aluminum stamping parts that can meet the demanding requirements of consumer electronics devices.