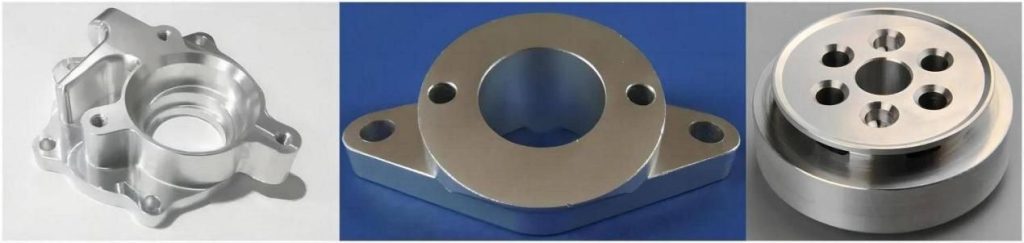

Aluminum stamping parts are a versatile and widely-used type of metal component used in various industries. The process of aluminum stamping is used to create parts with a specific shape or design by pressing or punching a sheet of aluminum with a die or mold. The result is a precise and uniform part with excellent strength and durability, making it an ideal material for many applications.

The properties of aluminum, including its high strength-to-weight ratio, excellent thermal conductivity, and corrosion resistance, make it a popular choice in industries where these characteristics are essential. Aluminum stamping parts are used in the automotive, electronics, and aerospace industries, among others.

Three main applications of aluminum stamping parts

Automotive Industry

The automotive industry is one of the largest consumers of aluminum stamping parts. Aluminum is a lightweight material that helps reduce vehicle weight and improve fuel efficiency. Aluminum stamping parts are used in various automotive components, such as car doors, hoods, and fenders. Aluminum stamping parts are often used in combination with other materials, such as steel or plastic, to improve the strength and durability of the final product.

One of the most significant advantages of using aluminum stamping parts in the automotive industry is its corrosion resistance. Aluminum does not rust, making it an ideal material for car components exposed to harsh weather conditions. The use of aluminum stamping parts also helps reduce noise and vibration levels in vehicles due to its excellent damping properties. The automotive industry is continuously looking for ways to improve fuel efficiency and reduce vehicle weight, making aluminum stamping parts a crucial component in the manufacturing process.

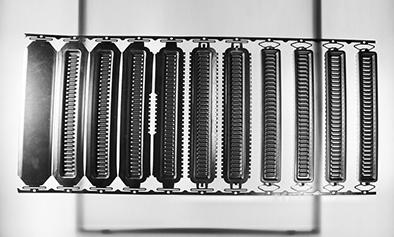

Electronics Industry

The electronics industry is another significant consumer of aluminum stamping parts. The use of aluminum in electronic components has increased in recent years due to its excellent thermal conductivity, which helps dissipate heat efficiently. Aluminum stamping parts are used in various electronic components, such as computer parts, mobile phones, and tablets.

One of the most significant advantages of using aluminum stamping parts in the electronics industry is its lightweight properties, which help reduce the weight of electronic devices. Aluminum stamping parts also offer high strength and durability, making it an ideal material for manufacturing high-performance electronic components. The use of aluminum stamping parts in the electronics industry is expected to increase due to the growing demand for lightweight, high-performance components in the market.

Aerospace Industry

The aerospace industry is also a significant consumer of aluminum stamping parts. The use of aluminum in aerospace components has increased significantly due to its lightweight properties, which help reduce aircraft weight and improve fuel efficiency. Aluminum stamping parts are used in various aerospace components, such as airplane fuselages and engine parts.

One of the most significant advantages of using aluminum stamping parts in the aerospace industry is its high strength-to-weight ratio, making it an ideal material for manufacturing lightweight and high-performance aerospace components. Aluminum stamping parts also offer excellent corrosion resistance, making it an ideal material for aircraft components exposed to harsh environmental conditions. The aerospace industry is continuously looking for ways to reduce aircraft weight and improve fuel efficiency, making aluminum stamping parts an essential component in the manufacturing process.

In conclusion, aluminum stamping parts are essential components in various industries due to their excellent properties, including high strength, lightweight, and corrosion resistance. The automotive, electronics, and aerospace industries are just a few examples of industries that rely on aluminum stamping parts to improve performance and reduce weight. As the demand for lightweight and high-performance components continues to increase, the use of aluminum stamping parts is expected to rise in the future. With the versatility and flexibility of the stamping process, aluminum stamping parts will continue to play a crucial role in modern manufacturing. If you want to know more about aluminum stamping parts, CHAL will give you professional answers and services.

Related Products

Related Articles