Aluminum stamping is a manufacturing process that uses a die and a press to create a specific shape out of a sheet of aluminum. The die is a negative of the desired shape, and the press applies force to the sheet of aluminum, causing it to conform to the shape of the die. Aluminum stamping can be used to create a wide variety of parts, these aluminum stamping parts have different types and wide applications.

What Are the Different Aluminum Stamping Parts in Different Industries?

Aluminum stamping is used in a wide variety of industries, including:

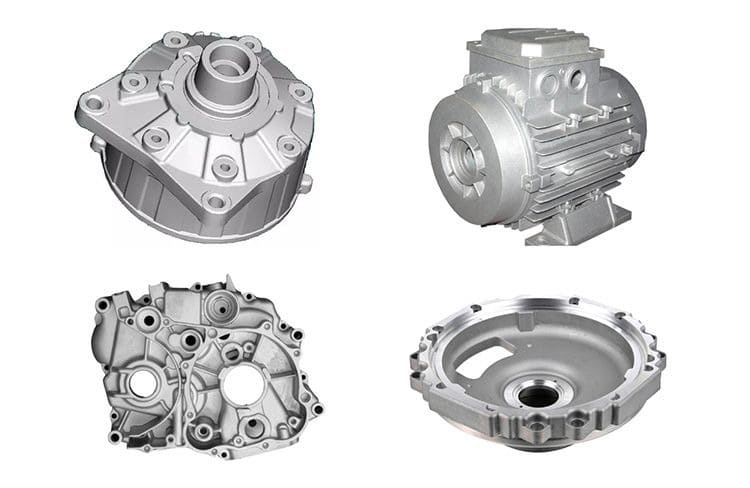

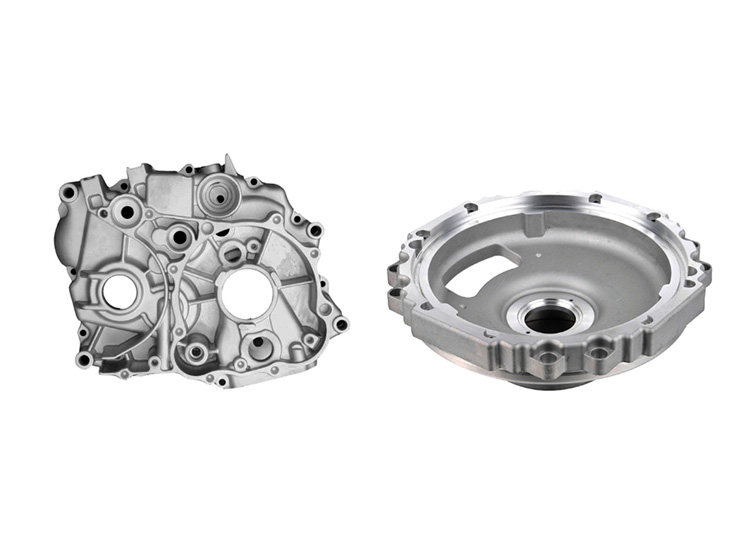

- Automotive: Aluminum stamping parts are used in a variety of automotive components, such as fenders, hoods, and doors.

- Aerospace: Aluminum stamping parts are used in a variety of aerospace components, such as aircraft fuselages and wings.

- Electronics: Aluminum stamping parts are used in a variety of electronic components, such as circuit boards and heat sinks.

- Machinery: Aluminum stamping parts are used in a variety of machinery components, such as gears and bearings.

- Medical: Aluminum stamping parts are used in a variety of medical devices, such as implants and surgical instruments.

- Packaging: Aluminum stamping parts are used in a variety of packaging applications, such as food packaging and beverage cans.

- Building and construction: Aluminum stamping parts are used in a variety of building and construction applications, such as windows and doors.

The specific types of aluminum stamping parts used in each industry vary depending on the specific requirements of the application.

What are the types of aluminum stamping parts?

There are many different types of aluminum stamping parts, each with its own unique set of characteristics and applications. Some of the most common types of aluminum stamping parts include:

- Blanks: Blanks are simple shapes that are cut out of a sheet of aluminum. They are often used as the starting point for other types of aluminum stamping parts, such as drawings and coinings.

- Drawings: Drawings are complex shapes that are created by stretching a sheet of aluminum over a die. They are often used for parts that require a high degree of precision, such as automotive body panels and aerospace components.

- Coinings: Coinings are high-precision parts that are created by pressing a sheet of aluminum against a die. They are often used for parts that require a mirror-like finish, such as jewelry and medical implants.

- Embossings: Embossings are raised or depressed patterns that are created on a sheet of aluminum. They are often used for decorative purposes, such as on packaging and furniture.

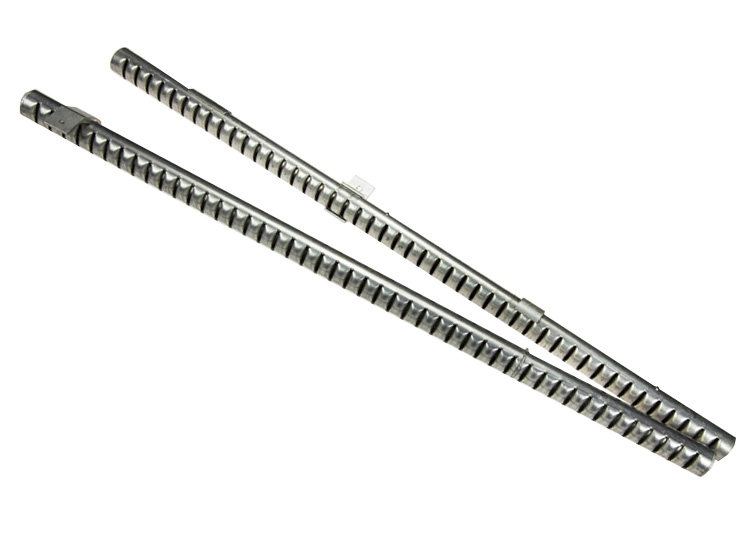

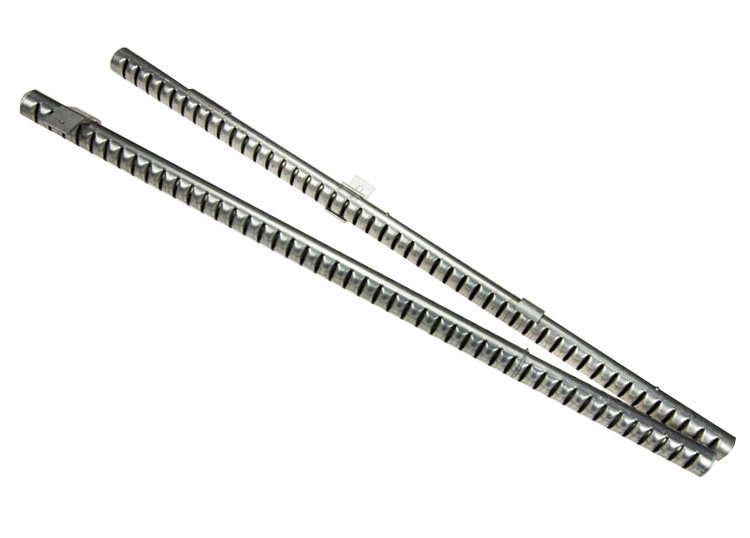

- Extrusions: Extrusions are long, thin parts that are created by forcing a billet of aluminum through a die. They are often used for structural components, such as window frames and railings.

Conclusion

The choice of aluminum stamping process depends on the specific requirements of the part being produced. For example, blanks are typically produced using a blanking press, while drawings are typically produced using a deep drawing press. Coinings and embossings are typically produced using a coining press, while extrusions are typically produced using an extrusion press.

The type of aluminum stamping process also affects the quality of the finished product. For example, blanks are typically lower quality than drawings, and coinings and embossings are typically higher quality than blanks.

The final choice of aluminum stamping process should be made in consultation with a qualified aluminum stamping manufacturer.