The automotive industry has seen a remarkable transformation over the years, driven by advancements in technology, materials, and design. One such innovation that has silently revolutionized modern automobiles is the Al-Al Composite Tube, often referred to as the “composite aluminum tube.” While it might not grab headlines like autonomous driving or electric vehicles, these tubes play a pivotal role in ensuring our comfort and well-being, especially when it comes to the air conditioning (AC) system. In this article, we will explore the significance of Al-Al Composite Tubes in the context of modern auto AC systems and their role as the backbone of this crucial component.

What is the AC System in Vehicles? Keeping Us Cool

Before delving into the role of Al-Al Composite Tubes, it’s essential to understand the importance of the air conditioning system in vehicles. Whether you’re commuting to work, embarking on a road trip, or stuck in traffic on a scorching summer day, the AC system is your ally in ensuring a comfortable and pleasant driving experience.

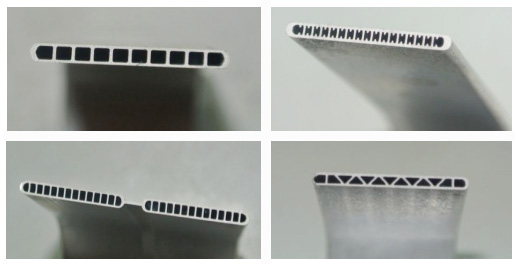

At the heart of every auto AC system lies the condenser header pipe, a component responsible for the crucial task of heat exchange. This is where Al-Al Composite Tubes come into play, reshaping the way we cool our vehicles. These tubes ensure that your car’s air conditioning operates efficiently and reliably, providing much-needed comfort during sweltering summers. By facilitating efficient heat exchange, they enable rapid cooling, allowing you to escape the heat with the touch of a button.

What are the Advantages of Al-Al Composite Tube?

So, what sets Al-Al Composite Tubes apart in the world of automotive AC systems? Here are 5 advatanges:

- Corrosion Resistance: The automotive environment can be harsh, with temperature fluctuations and exposure to various elements. Al-Al Composite Tubes exhibit remarkable corrosion resistance, ensuring the longevity and reliability of the condenser header pipe, even in demanding conditions.

- Lightweight Design: Weight reduction is a top priority in modern vehicle design, as it directly impacts fuel efficiency and overall performance. Al-Al Composite Tubes, constructed from aluminum, offer a lightweight solution that contributes to improved fuel efficiency and, consequently, lower emissions.

- Efficient Heat Transfer: Efficient heat exchange is critical for the effectiveness of the AC system. Al-Al Composite Tubes excel in this area due to their excellent thermal conductivity, ensuring rapid heat transfer and, consequently, quicker cooling of the cabin air.

- Durability: Automotive components must withstand a variety of stresses, including temperature fluctuations and vibrations. Al-Al Composite Tubes are known for their durability and resistance to fatigue, making them ideal for the demanding conditions within a vehicle’s AC system.

- Environmental Benefits:In an era where environmental sustainability is a top priority, Al-Al Composite Tubes offer additional advantages beyond their performance benefits. Their lightweight properties lead to reduced vehicle weight, which translates into lower fuel consumption and fewer emissions. This aligns with global efforts to reduce the automotive industry’s carbon footprint and promote eco-friendly practices.

Al-Al Composite Tubes in Auto Except AC Systems

Al-Al Composite Tubes have a variety of applications in the automotive industry beyond their role in auto AC systems. Here are some other notable applications:

- Exhaust Systems: Al-Al Composite Tubes are used in exhaust systems due to their corrosion resistance and lightweight properties. They help reduce the overall weight of the exhaust system, which can contribute to improved fuel efficiency and performance.

- Fuel Lines and Fuel Delivery Systems: These tubes are employed in the construction of fuel lines and fuel delivery systems. Their corrosion resistance ensures the integrity of the fuel system, preventing leaks and enhancing safety.

- Structural Components: Al-Al Composite Tubes can be used as structural components in vehicle frames and chassis. Their high strength-to-weight ratio contributes to improved vehicle safety and performance.

- Suspension Systems: In some cases, Al-Al Composite Tubes are utilized in the construction of suspension components. Their lightweight and durable nature can enhance ride comfort and handling.

Conclusion

As the automotive industry continues to prioritize sustainability, efficiency, and performance, Al-Al Composite Tubes have emerged as unsung heroes. In the context of modern auto AC systems, these tubes are the backbone of a component that keeps us comfortable during our journeys.

Their unique combination of corrosion resistance, lightweight design, efficient heat transfer, and durability has reshaped the way we cool our vehicles. In doing so, they not only enhance our driving experience but also contribute to environmental sustainability by reducing fuel consumption and emissions.

In the grand scheme of automotive innovation, Al-Al Composite Tubes may not be in the spotlight, but their influence is undeniable. As we look to the future of automotive design, these tubes will continue to play a vital role in ensuring that our vehicles provide comfort and efficiency while minimizing their impact on the environment. They are a testament to the power of innovation in shaping the vehicles we drive today and those we will drive tomorrow.