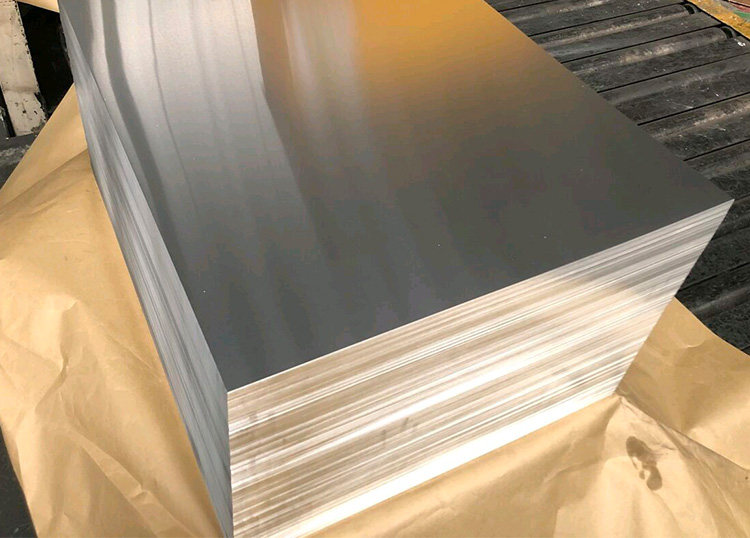

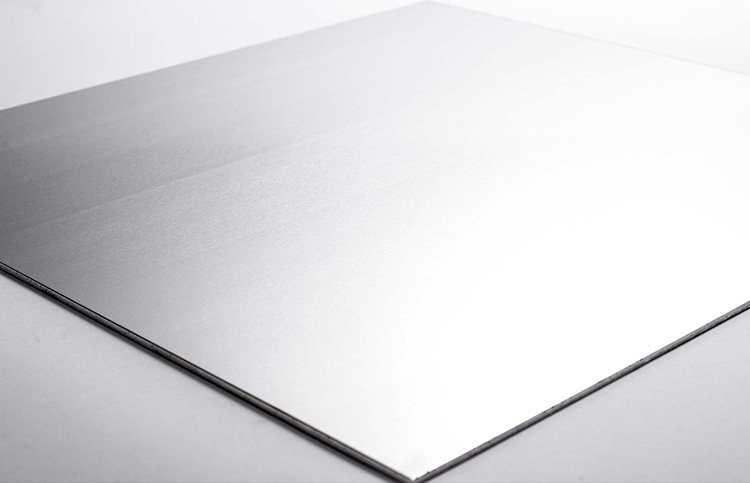

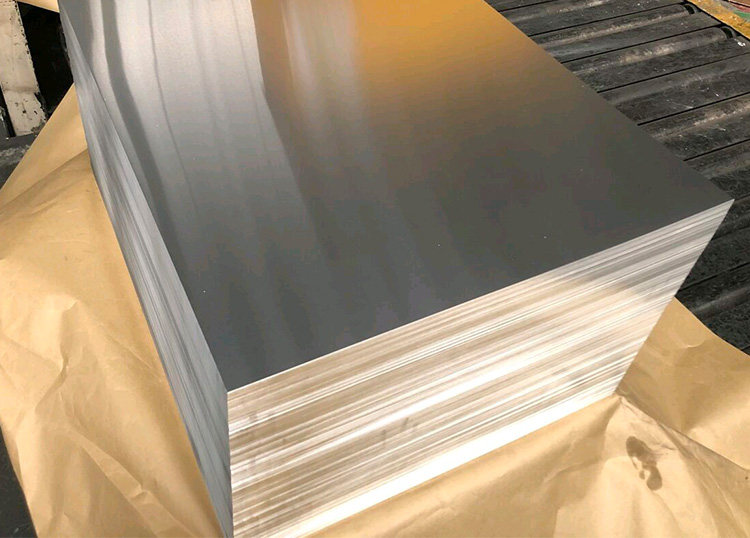

Tank cars play a critical role in the transportation of various liquids and gases, ranging from petroleum products to chemicals. The design and materials used in tank car construction significantly impact safety, efficiency, and environmental sustainability. In recent years, there has been a notable shift towards incorporating innovative materials like 5454 aluminum alloy in tank car design. This article explores the attributes of 5454 aluminum and its applications in revolutionizing tank car manufacturing.

Understanding 5454 Aluminum

5454 aluminum alloy is a versatile material renowned for its exceptional properties and suitability for various industrial applications.

Properties of 5454 Aluminum

- Composition: Composed primarily of aluminum, with magnesium as the primary alloying element, along with traces of manganese, chromium, and copper, 5454 aluminum exhibits a unique combination of properties that make it ideal for tank car design.

- Properties: Known for its superior workability, weldability, and resistance to corrosion, particularly in marine environments.

- Characteristics: Offers excellent formability, allowing for complex shapes in tank car construction.

Comparison with Other Materials for Tank Car

In comparison to other materials commonly used in tank car construction, such as steel or stainless steel, 5454 aluminum offers several distinct advantages. While steel exhibits high strength and durability, it is prone to corrosion, particularly in corrosive environments. Stainless steel, although resistant to corrosion, is heavier and more expensive than aluminum.

5454 aluminum strikes a balance between strength, corrosion resistance, and weight, making it a preferred choice for tank car manufacturers seeking to optimize performance and efficiency. Its favorable properties make it a cost-effective solution for meeting stringent regulatory requirements while ensuring the safe and reliable transportation of hazardous materials.

In summary, 5454 aluminum stands out as an innovative solution for tank car design, offering a compelling combination of corrosion resistance, formability, weldability, and lightweight construction. As the transportation industry continues to evolve, the adoption of 5454 aluminum is poised to drive advancements in tank car technology, enhancing safety, efficiency, and environmental sustainability.

Advantages of 5454 Aluminum in Tank Car Design

The advantages of using 5454 aluminum in tank car design are manifold, encompassing various aspects crucial to the efficient and safe transportation of liquids, gases, and hazardous materials. Some of the key advantages include:

- Corrosion Resistance: One of the most significant advantages of 5454 aluminum is its exceptional resistance to corrosion, particularly in marine and industrial environments. This property ensures the longevity and reliability of tank cars, reducing maintenance requirements and minimizing the risk of leaks or structural failures.

- Lightweight Construction: 5454 aluminum is significantly lighter than traditional materials such as steel, making it an attractive choice for tank car construction. The lightweight nature of aluminum enables operators to increase payload capacity, improve fuel efficiency, and reduce operational costs without compromising safety or structural integrity.

- Formability and Weldability: 5454 aluminum exhibits excellent formability and weldability, allowing for the fabrication of seamless tank structures and complex geometries. This flexibility in design facilitates efficient manufacturing processes and enables the creation of custom solutions tailored to specific application requirements.

- High Strength-to-Weight Ratio: Despite its lightweight construction, 5454 aluminum offers impressive strength and durability. The alloy’s high strength-to-weight ratio ensures the structural integrity of tank cars while minimizing overall weight, contributing to enhanced performance and efficiency.

- Environmental Sustainability: Aluminum is a highly recyclable material, and 5454 aluminum is no exception. The use of aluminum in tank car design promotes environmental sustainability by reducing the consumption of finite resources and minimizing waste. Additionally, the recyclability of aluminum supports circular economy principles and reduces the carbon footprint of tank car manufacturing.

- Compliance with Regulatory Standards: Tank cars must adhere to stringent regulatory standards and safety requirements to ensure the secure transportation of hazardous materials. 5454 aluminum’s corrosion resistance, durability, and other favorable properties enable tank cars to meet or exceed these regulatory standards, providing peace of mind to operators, regulators, and the public.

- Cost-Effectiveness: While the initial investment in 5454 aluminum may be higher than some other materials, the long-term cost-effectiveness of aluminum tank cars is evident. The reduced maintenance, increased payload capacity, and improved fuel efficiency associated with aluminum construction result in lower operational costs over the lifespan of the tank car.

Overall, the advantages of 5454 aluminum in tank car design make it a preferred choice for manufacturers and operators seeking to optimize safety, efficiency, and environmental sustainability in the transportation of hazardous materials. By leveraging the unique properties of 5454 aluminum, tank car designs can achieve unparalleled performance and reliability in various industrial applications.

Applications of 5454 Aluminum in Tank Car Design

The specific applications of 5454 aluminum in tank car design encompass various critical components and structural elements aimed at ensuring safety, durability, and efficiency in the transportation of liquids, gases, and other hazardous materials. Some specific applications include:

- Tank Shell Construction: 5454 aluminum is frequently utilized in the fabrication of tank shells due to its excellent formability and weldability. The alloy’s ability to be formed into complex shapes enables the creation of seamless tank structures, reducing the risk of leaks and enhancing structural integrity.

- Tank Heads and Domes: The superior corrosion resistance of 5454 aluminum makes it well-suited for manufacturing tank heads and domes. These components play a crucial role in containing and protecting the contents of the tank, and the corrosion-resistant properties of 5454 aluminum ensure long-term reliability.

- Baffles and Bulkheads: Baffles and bulkheads are internal partitions within the tank that help control the movement of liquids during transportation, preventing sloshing and maintaining stability. 5454 aluminum’s lightweight yet durable nature makes it ideal for fabricating these components, contributing to overall safety and efficiency.

- Manways and Access Hatches: Manways and access hatches provide entry points for inspection, maintenance, and loading/unloading operations. 5454 aluminum is commonly used in the construction of these components due to its corrosion resistance and ease of fabrication.

- Structural Components: Various structural components of tank cars, such as support beams, brackets, and reinforcements, may be fabricated using 5454 aluminum. The alloy’s strength, ductility, and weldability ensure the structural integrity of the tank car while minimizing weight.

- Piping and Fittings: Piping systems within the tank car, including inlet and outlet pipes, valves, and fittings, may incorporate 5454 aluminum components. The corrosion-resistant properties of the alloy help maintain the integrity of the fluid containment system.

- Heat Exchangers and Cooling Systems: In specialized tank cars designed for transporting temperature-sensitive materials, 5454 aluminum may be used in the construction of heat exchangers and cooling systems. The alloy’s thermal conductivity and corrosion resistance make it suitable for such applications.

Overall, the specific applications of 5454 aluminum in tank car design encompass a wide range of components and structural elements essential for ensuring the safe and efficient transportation of hazardous materials.

Conclusion

The integration of 5454 aluminum alloy in tank car design represents a significant advancement in the transportation of liquids and gases. Its unique combination of properties, including corrosion resistance, lightweight, and recyclability, offers substantial benefits in terms of safety, cost-effectiveness, and environmental sustainability. As the industry continues to prioritize efficiency and safety in hazardous material transportation, the use of 5454 aluminum is poised to become increasingly prevalent in tank car manufacturing, shaping the future of this critical sector. If you are looking for a 5454 aluminum plate supplier, please feel free to contact CHAL, believe they will not let you down.