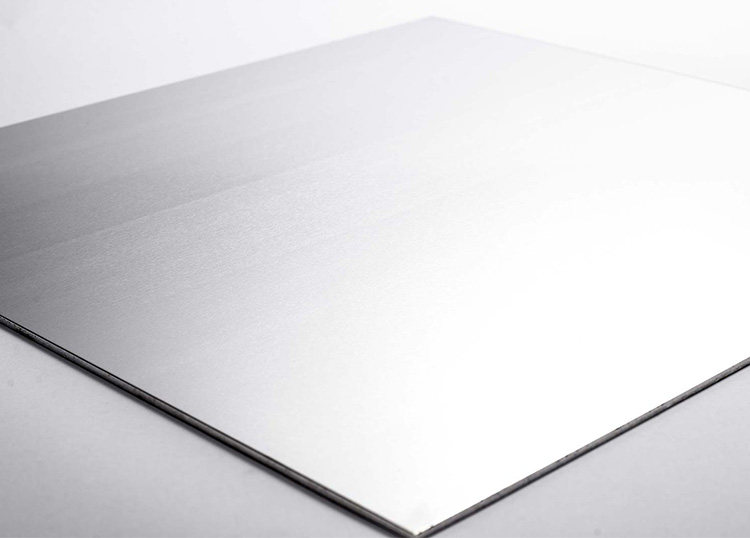

In today’s rapidly evolving world, the quest for sustainability has become paramount across industries. From manufacturing to consumer goods, companies are increasingly turning to sustainable materials and practices to reduce their environmental footprint. One such material making waves in the packaging industry is 3105 aluminum sheet. Renowned for its versatility, durability, and eco-friendly attributes, the 3105 aluminum sheet stands out as a sustainable choice for packaging solutions.

Understanding 3105 Aluminum Sheet

3105 aluminum belongs to the 3xxx series of aluminum alloys, renowned for their exceptional corrosion resistance and formability. Composed primarily of aluminum with additions of magnesium and manganese, 3105 aluminum sheet exhibits remarkable strength-to-weight ratio, making it an ideal material for packaging applications.

Sustainable Packaging Trends

The shift towards sustainable packaging is driven by consumer demand for eco-friendly products and corporate responsibility initiatives. Conventional packaging materials like plastics and foils pose significant environmental challenges, including pollution and resource depletion. In contrast, aluminum offers a compelling solution due to its recyclability, durability, and minimal environmental impact.

Advantages of 3105 Aluminum Sheet in Packaging

3105 aluminum sheet offers several advantages for packaging applications, making it a popular choice for various industries. Here are some key benefits:

Durability and Corrosion Resistance:

- Excellent corrosion resistance: Thanks to the addition of magnesium, manganese, and silicon, 3105 aluminum possesses superior resistance to rust and corrosion, making it ideal for packaging products exposed to moisture or harsh environments.

- High strength and formability: This alloy offers good mechanical strength and formability, allowing it to be easily shaped into complex packaging designs without compromising integrity.

Versatility and Sustainability:

- Lightweight: Compared to other packaging materials like steel or glass, 3105 aluminum is significantly lighter, reducing transportation costs and environmental impact.

- Recyclable: Aluminum is one of the most recyclable metals, with over 70% of all aluminum ever produced still in use today. This makes 3105 aluminum a sustainable choice for environmentally conscious brands.

- Food-safe: When properly treated, 3105 aluminum can be used for food packaging as it complies with food safety regulations. Its non-toxic nature and ability to preserve food freshness make it ideal for various food items.

Additional advantages:

- Good electrical conductivity: This property can be beneficial for certain packaging applications requiring heat dissipation or shielding from electromagnetic interference.

- Welds well: 3105 aluminum offers good weldability, allowing for the creation of stronger and more complex packaging structures.

- Paintable and printable: The smooth surface of this aluminum sheet makes it suitable for various printing and painting techniques, enabling attractive and informative packaging designs.

However, it’s important to consider some limitations:

- Not heat-treatable: Unlike some other aluminum alloys, 3105 cannot be strengthened through heat treatment, limiting its use in applications requiring high strength at elevated temperatures.

- Cost: While generally less expensive than some other metals, 3105 aluminum might be costlier than certain plastic alternatives.

Overall, 3105 aluminum sheet offers a compelling combination of durability, versatility, and sustainability, making it a valuable choice for various packaging applications.

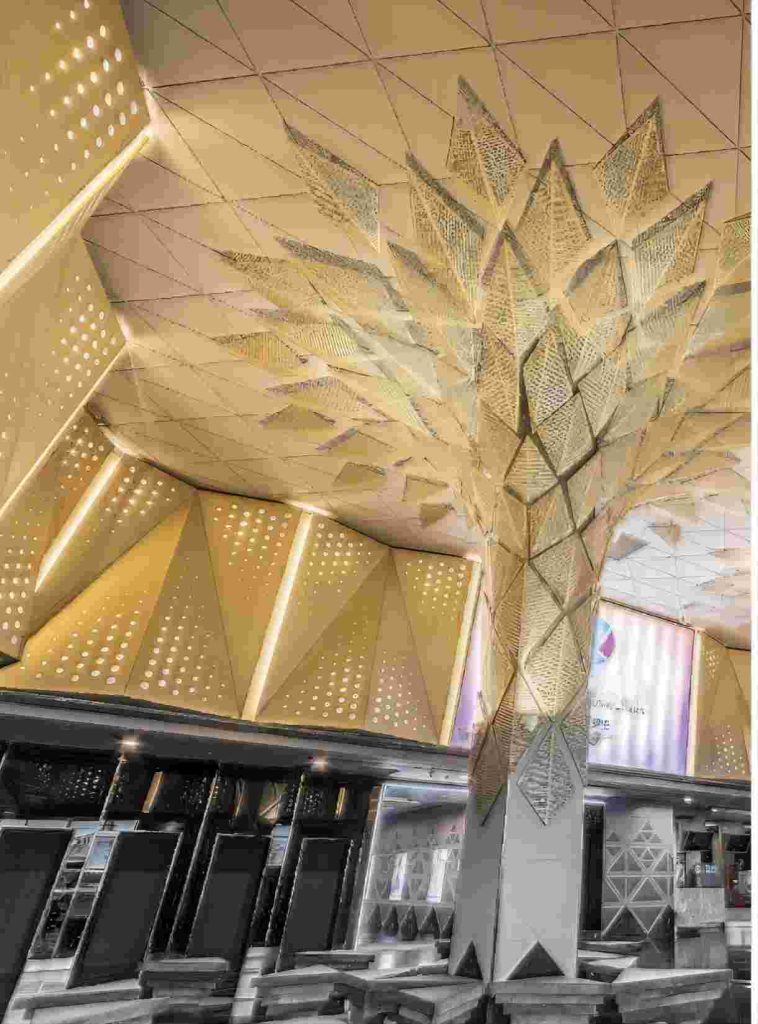

Applications of 3105 Aluminum Sheet in Packaging

3105 aluminum sheet finds applications in a wide range of packaging scenarios due to its advantageous properties. Here are some key areas where it shines:

1. Food and Beverage:

- Lids and closures: Screw caps for beverage bottles and jars, yogurt lids, and similar closures benefit from 3105’s strength, formability, and food-safe properties.

- Foil containers: Trays, wraps, and pouches for various food items utilize 3105’s lightweight, formability, and barrier properties to preserve freshness and extend shelf life.

- Flexible packaging: Laminated structures often incorporate 3105 for its strength, barrier properties, and printability, ideal for coffee pouches, snack bags, and other flexible packaging solutions.

2. Pharmaceutical and Cosmetics:

- Blister packs and capsules: 3105’s formability and barrier properties are crucial for creating secure and tamper-evident packaging for pills and capsules.

- Aerosol cans: The strength and corrosion resistance of 3105 make it suitable for pressurized containers used in personal care and pharmaceutical aerosols.

3. Other Applications:

- Resealable pouches: Stand-up pouches with resealable zippers often use 3105 for its strength and formability, offering convenient packaging for snacks, pet food, and other dry goods.

- Rigid containers: Formed trays and containers for various products leverage 3105’s strength and printability, creating attractive and durable packaging solutions.

- Folding cartons: Laminated carton structures sometimes incorporate 3105 for added strength and barrier properties, ideal for high-end food and cosmetic packaging.

- Industrial packaging: Due to its strength and corrosion resistance, 3105 finds use in packaging for chemicals, lubricants, and other industrial products.

It’s important to note that the specific applications depend on factors like:

- Thickness and temper of the aluminum sheet: Different gauges and tempers offer varying strength and formability characteristics for specific needs.

- Surface treatments and coatings: Coatings can enhance barrier properties, printability, and food safety depending on the application.

- Combination with other materials: 3105 is often laminated with other materials like paper or plastic to achieve specific performance requirements.

By understanding the advantages and limitations of 3105 aluminum sheet, designers and manufacturers can choose the right material for their specific packaging needs, ensuring optimal performance, sustainability, and cost-effectiveness.

Conclusion

In an era defined by sustainability challenges, 3105 aluminum sheet emerges as a beacon of hope for the packaging industry. Its inherent properties and eco-friendly attributes position it as a sustainable choice for companies striving to minimize their environmental footprint while delivering quality products to consumers. By partnering with a 3105 aluminum sheet supplier – CHAL, businesses can pave the way towards a more sustainable future for packaging solutions.

As industries continue to evolve, the adoption of sustainable materials like 3105 aluminum sheet will play a pivotal role in shaping a greener, more resilient world. Together, let us embrace the power of innovation and sustainability to build a brighter tomorrow, one package at a time.