Why use copper foil for the negative electrode of the current collector of a lithium-ion battery and aluminum foil for the positive electrode?

The positive current collector usually used in lithium-ion batteries is aluminum foil, and the negative current collector is copper foil. The main function of the current collector is to conduct electricity. This is similar to the material of our wires and also uses copper wire or aluminum wire. This is because conductors can be divided into silver→copper→gold→aluminum→tungsten→nickel→iron according to their conductivity. The best is definitely silver, but precious metal elements are rare after all, and copper and aluminum are rich in resources in the world, and the price is relatively cheap.

At the same time, in lithium batteries, we mainly have two processing methods: winding and lamination. Compared with winding, the pole piece used to prepare the battery needs to have a certain degree of flexibility to ensure that the pole piece does not suffer from brittleness during winding. Among the metal materials, copper aluminum foil is also a softer metal. On the other hand, copper and aluminum foil is relatively stable in the air. Aluminum is easy to chemically react with oxygen in the air, forming a dense oxide film on the aluminum surface layer to prevent further aluminum reaction, and this thin oxide film also has a certain protective effect on aluminum in the electrolyte. Copper itself is relatively stable in air, and basically does not react in dry air. The oxide layer on the copper/nickel surface is a semiconductor, and the electrons are conductive; while the oxide layer on the aluminum surface, aluminum oxide is an insulator, and the oxide layer cannot conduct electricity, but because it is very thin, the electron conduction is realized through the tunnel effect. If the oxide layer is thick, the impedance is larger, with poor conductivity and even insulation. Generally, the surface of the current collector should be cleaned before use. On the one hand, it can wash off the oil stains and at the same time remove the thick oxide layer.

The potential of the positive and negative electrodes of a lithium battery determines that the positive electrode uses aluminum foil and the negative electrode uses copper foil, rather than the other way around. The positive electrode potential is high, the copper/nickel foil oxide layer is looser, and it is easily oxidized at high potential, while the oxidation potential of aluminum is high, and the surface of the aluminum foil has a dense oxide film, which also has a better protective effect on the aluminum inside.

Another point is that aluminum will undergo an alloying reaction with lithium at low potential (for example, the negative electrode is lithium 0 V or graphite 0.2 V) and is consumed. The size of the octahedral voids of metallic aluminum is similar to that of Li, and it is easy to form interstitial compounds with Li. Li and Al not only form an alloy with the chemical formula Li Al, but may also form Li3Al2 or Li4Al3. Due to the high activity of the reaction between metal Al and Li, the metal Al consumes a large amount of Li, and its structure and morphology are also destroyed, so it cannot be used as the current collector of the negative electrode of the lithium-ion battery; and Cu during the charging and discharging process of the battery, There is little lithium insertion capacity, and the structure and electrochemical performance are kept stable. It can be used as the current collector of the negative electrode of lithium-ion battery; but if the copper/nickel surface is oxidized in a large amount, Li will interact with copper oxide/nickel at a slightly higher potential. When the lithium intercalation occurs, when the Cu foil is at 3.75V, the polarization current starts to increase significantly, and it rises linearly, and the oxidation intensifies, indicating that Cu becomes unstable at this potential; while the aluminum foil is polarized in the entire polarization potential range. The current is small and constant, no obvious corrosion phenomenon is observed, and the stability of electrochemical performance is maintained. As in the positive electrode potential range of lithium-ion batteries, Al has a small lithium insertion capacity and can maintain electrochemical stability, making it suitable for use as a positive electrode current collector for lithium-ion batteries. If a high-potential negative electrode (lithium titanate 1.5 V) is used, aluminum foil can also be used as the current collector.

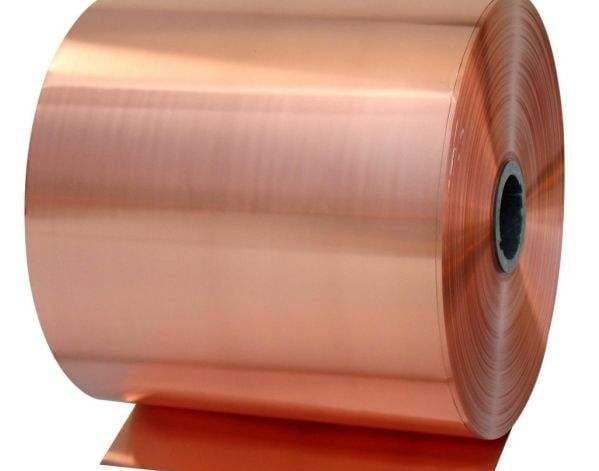

Purity requirements of copper foil and aluminum foil used in lithium batteries

To ensure the stability of the current collector inside the battery, the purity of both aluminum foil and copper foil is required to be above 98%. The impure Al composition will cause the surface film to be not dense and cause pitting corrosion, and even the destruction of the surface film leads to the formation of LiAI alloy.

Thickness requirements of copper foil and aluminum foil for lithium batteries

With the rapid development of lithium batteries in recent years, the development of current collectors for lithium batteries has also been rapid. The positive aluminum foil has been reduced from 16um to 14um and then to 12um in previous years. Now many battery manufacturers have mass-produced aluminum foil of 10um, even 8um. As for the copper foil for the negative electrode, due to its better flexibility, its thickness has been reduced from 12um to 10um and then to 8um. Up to now, a large number of battery manufacturers use 6um in mass production, and some manufacturers are developing 5um/4um. It’s all possible to use. Since lithium batteries require high purity of the copper and aluminum foil used, the density of the materials is basically at the same level. As the thickness of the development decreases, the areal density also decreases, and the weight of the battery is naturally getting smaller and smaller, which is in line with our requirements for lithium batteries. need.

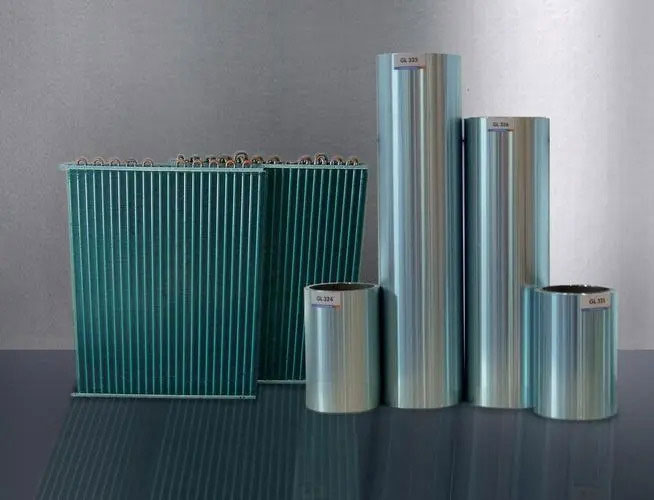

In order to better match the lithium battery, it is now possible to produce special battery aluminum foil. For example, CHAL’s battery aluminum foil series. Special battery aluminum foil, its design is more in line with the characteristics of lithium batteries, can better act on lithium batteries.

At the end of the article, if you want to know more about CHAL’s aluminum foil, please visit our homepage – CHAL to learn more.