Since the beginning of this year, the new energy vehicle market has continued its high growth trend in the fourth quarter of last year, driving a significant increase in the installed power of power batteries and a substantial increase in the market demand for lithium battery aluminum foil. According to relevant statistics, the amount of aluminum foil per GW of lithium batteries is 600-800 tons. Industry insiders predict that the global demand for lithium battery aluminum foil will be about 192,000 tons in 2021, an increase of 45%. The existing production capacity may be in short supply. The supply and demand gap will increase to 11,000 tons in 2022, and it will continue to expand in 2023. So what is battery aluminum foil? What is the use of battery aluminum foil? After reading this article, you will get the answer.

What is battery aluminum foil?

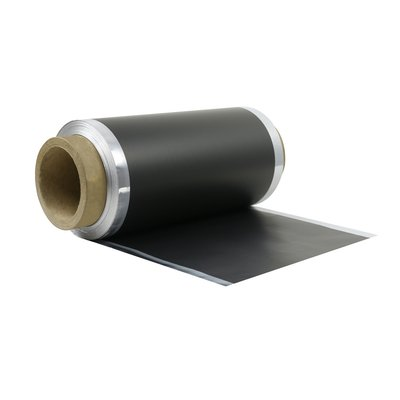

Just like its name, battery aluminum foil is a refined product of aluminum foil. Rolling ordinary aluminum foil with a thickness ranging from 10 to 50 microns can be used to obtain battery aluminum foil for lithium batteries. Commonly used pure aluminum foils for lithium batteries have various alloy grades such as 1060, 1050, 1145, 1235, etc., and are in -O, H14, -H24, -H22, -H18 and other states.

The latest research in the lithium-ion battery industry has found that by etching and roughening the surface of the aluminum (Al) alloy foil used as the positive collector of the lithium-ion rechargeable battery, the charge and discharge characteristics of the battery can be improved. Compared with the aluminum foil without surface treatment, the binding force between the aluminum foil and the active material after the surface roughening treatment has significantly improved the charging and discharging characteristics of the battery. This plays an important role in the development of rechargeable batteries for hybrid and electric vehicles, as well as rechargeable batteries for power storage for wind power generation and solar power generation.

What are the characteristics of battery aluminum foil?

The production of battery aluminum foil must fully consider the thermal conductivity, electrical conductivity and mechanical strength of the aluminum foil. Using special blanks, in a clean and dust-removing plant environment, manufactured by high-precision imported rolling mills with online profile rolls and Siemens control systems.

Features

1. The aluminum foil rolling mill equipment is equipped with an advanced automatic thickness control system and an automatic shape control system to achieve precise control of the shape and thickness;

2. Select aluminum foil blanks, strictly control the hydrogen content of the blanks, the amount of non-metallic slag and the grain size, and ensure the product quality from the raw materials;

3. Using advanced online degreasing technology to ensure the cleanliness of the aluminum foil on the basis of ensuring the mechanical strength of the aluminum foil.

Specification model

| Alloy model | 1235 | 1145 | 1060 | 1070 |

| state | H18 | H18 | H18 | H18 |

| tensile strength | ≥150N/mm | |||

| Elongation | ≥1% | |||

* Resistance of 1145 and 1235 alloy aluminum foil with different thicknesses (width 10mm)

| Standard thickness/mm | 0.0060 | 0.0070 | 0.0080 | 0.0090 | 0.010 | 0.11 | 0.16 |

| Maximum resistance/(Ω.m) | 0.55 | 0.51 | 0.43 | 0.36 | 0.32 | 0.28 | 0.25 |

* The choice of battery aluminum foil material needs to be judged according to the required use.

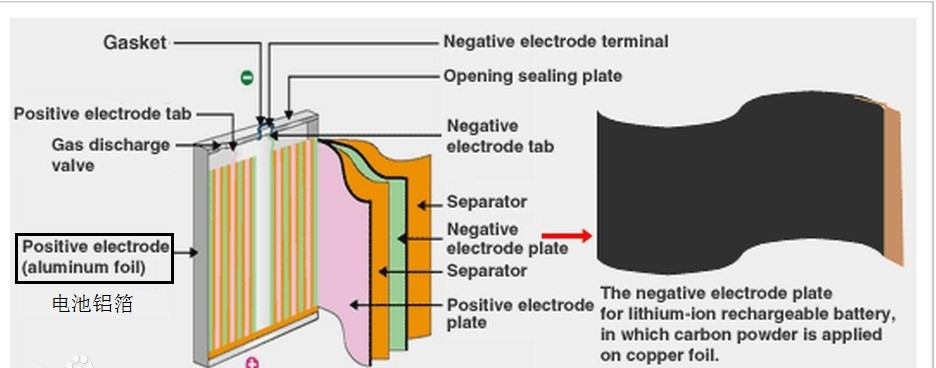

Where is the aluminum foil in the lithium battery?

Lithium batteries usually have cylindrical and square shapes. The inside of the battery adopts a spiral wound structure, and a very fine and highly permeable polyethylene film separator is used to separate the positive and negative electrodes. The positive electrode includes a current collector composed of lithium cobalt oxide (or lithium nickel cobalt manganate, lithium manganate, lithium iron phosphate, etc.) and aluminum foil. The negative electrode is composed of a current collector composed of graphitized carbon material and copper foil. The battery is filled with organic electrolyte solution, and is also equipped with a safety valve and PTC components (partially cylindrical) to protect the battery from damage in abnormal conditions and output short circuits.

How to choose high-quality battery aluminum foil?

Quality requirements

- The surface of the aluminum foil is uniform in color, clean, and flat, without obvious roll marks, pitting, pinholes, and corrosion marks;

- There are no rolling defects such as creases, mottling, bright lines, etc. on the surface of the aluminum foil;

- There is no color difference on the surface of the aluminum foil;

- No oil on the surface, no serious oil odor, and no visible oil spots;

- Surface tension, dyne pen test is not less than 32 dyne.

Appearance requirements

- The aluminum foil coil is wound tightly, the end surface is flat and clean, and the edge is smooth;

- The staggered layer of aluminum foil shall not exceed ±1.0mm;

- The width of the aluminum foil roll tube core is greater than or equal to the foil width, and generally the length of the two ends of the tube core does not exceed the foil width of 5mm;

- The aluminum foil should be wrapped around the center of the tube core;

- The joint part has clear joint marks on the two ends of the aluminum coil.

But under normal circumstances, the battery aluminum foil produced in the same batch may also have uneven quality. Therefore, choosing a reliable battery aluminum foil supplier is the most important thing. CHAL Aluminium Corporation is a fully integrated aluminium company that provides all kinds of aluminium products and technical solutions. We have been providing high-quality battery aluminum foil to major companies around the world. Our product line includes high-purity etched Al foil and battery-grade foils made from various alloys (1050,1060,1070,1100,1235). If you have any needs, please contact us and we will try our best to provide you with suitable battery aluminum foil.