For centuries, paper has reigned supreme as the primary medium for printing. However, the world of printing is constantly evolving, and new materials are emerging to offer unique advantages. Aluminum substrate is one such innovation, pushing the boundaries of what’s possible in the printing industry. This article delves into the realm of aluminum substrate printing, exploring its characteristics, printing techniques, applications, challenges, and the potential it holds for the future of the printing industry.

What is Aluminum Substrate?

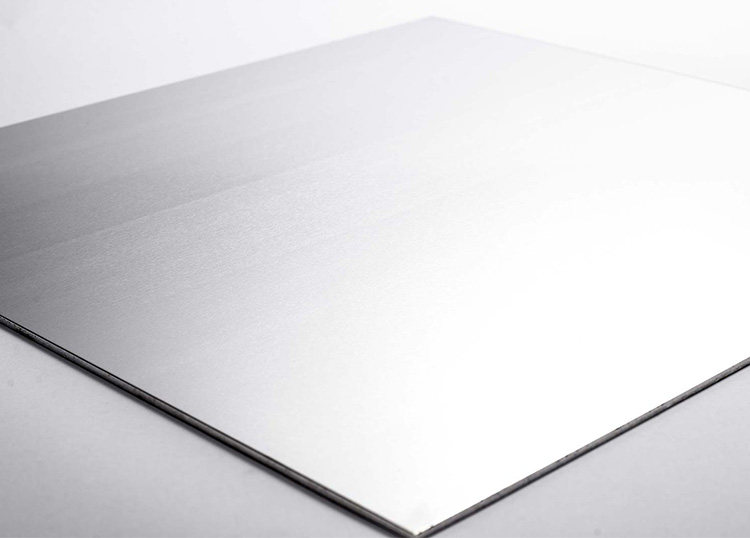

Aluminum substrate refers to the use of aluminum sheets or foils as the base material for printing instead of traditional paper. Aluminum offers unique properties that make it an attractive substrate for printing. It is lightweight yet durable, resistant to moisture, chemicals, and tearing, and possesses a smooth surface conducive to high-quality printing.

Advantages of Aluminum Substrate over traditional paper in Printing

Aluminum substrate offers several advantages over traditional paper in printing, making it an attractive option for various applications:

- Durability: Aluminum substrate is highly durable and resistant to tearing, moisture, and chemicals compared to paper. This durability ensures that prints on aluminum substrate have a longer lifespan, making them suitable for outdoor signage, industrial labels, and packaging materials that require robustness.

- Weather Resistance: Prints on aluminum substrate are resistant to fading, warping, and damage from exposure to sunlight, humidity, and extreme temperatures. This weather resistance makes aluminum prints ideal for outdoor applications where durability and longevity are paramount.

- Vibrant Colors and High Resolution: The smooth surface of aluminum substrate allows for excellent ink adhesion, resulting in prints with vibrant colors, sharp details, and high-resolution imagery. This makes aluminum substrate printing particularly suitable for applications such as photography, art reproduction, and decorative panels where image quality is crucial.

- Versatility: Aluminum substrate can be used for a wide range of printing applications across various industries, including advertising, packaging, architecture, and industrial labeling. Its versatility allows for the creation of diverse products such as signage, labels, nameplates, decorative panels, and promotional materials.

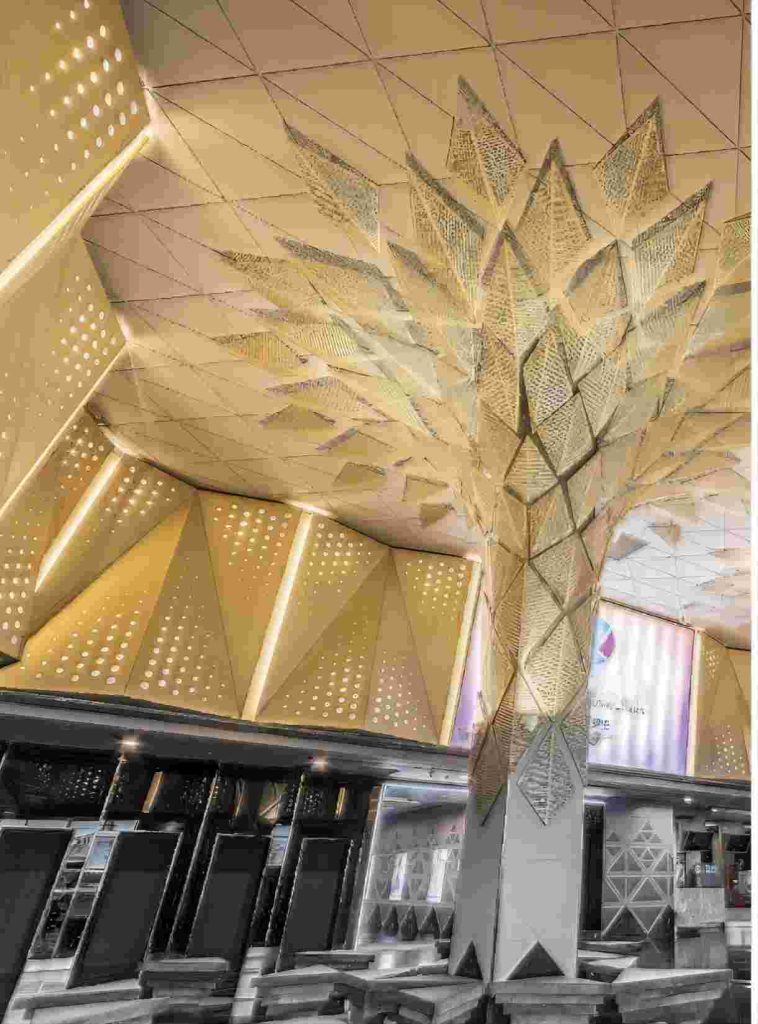

- Modern Aesthetic: Prints on aluminum substrate have a modern and sleek aesthetic that adds sophistication and visual appeal to products and environments. The metallic sheen of aluminum substrate enhances the appearance of prints, making them stand out and grab attention.

- Customization and Personalization: Aluminum substrate printing allows for customization and personalization of prints, enabling businesses to create unique and tailored products for their customers. This flexibility makes aluminum substrate printing suitable for producing personalized gifts, promotional items, and branded materials.

- Environmental Benefits: While aluminum substrate printing requires energy-intensive manufacturing processes, aluminum is highly recyclable and can be reused indefinitely without losing its quality. Additionally, aluminum prints have a longer lifespan than paper prints, reducing the need for frequent replacements and minimizing waste.

Overall, the advantages of aluminum substrate over traditional paper in printing include durability, weather resistance, vibrant colors, versatility, modern aesthetic, customization options, and environmental benefits. These qualities make aluminum substrate printing an attractive choice for businesses looking to create high-quality, long-lasting prints for a variety of applications.

Printing Techniques on Aluminum

Printing on aluminum substrate can be achieved through various techniques, each offering unique advantages depending on the specific requirements of the project. Here are some of the common printing techniques used for aluminum substrate:

- Digital Printing: Digital printing on aluminum involves transferring digital images directly onto the substrate using specialized inkjet printers. This technique offers high-resolution printing with vibrant colors and intricate details. Digital printing is ideal for small to medium-sized print runs and is commonly used for applications such as photography, art reproduction, signage, and personalized products.

- Offset Printing: Offset printing on aluminum utilizes the process of lithography, where ink is transferred from a plate onto a rubber blanket before being applied to the aluminum substrate. This technique is well-suited for large-scale production runs of high-quality prints. Offset printing offers precise color reproduction, sharp details, and consistent results, making it suitable for packaging materials, labels, posters, and promotional materials.

- Screen Printing: Screen printing on aluminum involves pressing ink through a mesh screen onto the substrate, creating bold, opaque designs. This technique is versatile and can be used to print on various surfaces, including flat, curved, and irregularly shaped substrates. Screen printing is commonly used for industrial applications, outdoor signage, decals, and decorative panels.

- Sublimation Printing: Sublimation printing involves transferring dye onto a substrate using heat and pressure, where the dye sublimates and bonds with the surface of the substrate. Aluminum substrate with a specialized coating can be used for sublimation printing, resulting in vibrant, durable prints with excellent color reproduction. Sublimation printing is commonly used for producing personalized items such as photo gifts, plaques, nameplates, and signage.

- UV Printing: UV printing on aluminum involves curing UV ink with ultraviolet light, resulting in fast-drying prints with vibrant colors and excellent adhesion. UV printing is suitable for printing on a wide range of substrates, including aluminum, glass, acrylic, and wood. This technique offers high-resolution printing with sharp details and is commonly used for signage, displays, promotional items, and industrial labels.

- Pad Printing: Pad printing on aluminum involves transferring ink from a silicone pad onto the substrate using a printing plate. This technique is well-suited for printing on small, irregularly shaped objects and offers precise registration and consistent results. Pad printing is commonly used for industrial applications, electronic components, medical devices, and promotional products.

These printing techniques offer versatility, precision, and quality, making them suitable for various applications on aluminum substrate. By choosing the appropriate printing technique based on the specific requirements of the project, businesses can achieve high-quality prints with vibrant colors, sharp details, and long-lasting durability.

Applications of Aluminum Printing

Aluminum printing offers a wide range of applications across various industries, thanks to its durability, versatility, and aesthetic appeal. Here are some common applications of aluminum printing:

| Application | Specific Products | Printing Techniques |

| Signage and Advertising | Storefront signs, Billboards, Banners, Directional signage, Advertising displays | Digital Printing, Offset Printing, Screen Printing, UV Printing |

| Packaging | Food packaging, Beverage packaging, Cosmetic packaging, Pharmaceutical packaging, Product labels | Digital Printing, Offset Printing, Sublimation Printing, UV Printing |

| Decorative Panels and Wall Art | Wall art prints, Decorative panels, Room dividers, Architectural cladding, Customized artwork | Digital Printing, Sublimation Printing, UV Printing |

| Industrial Labels and Nameplates | Equipment labels, Asset tags, Safety signage, Compliance labels, Serial number plates | Digital Printing, Screen Printing, Pad Printing |

| Promotional Products | Branded merchandise – Keychains, Coasters, Magnets; Personalized gifts – Photo prints, Plaques, Awards | Digital Printing, Sublimation Printing |

| Architectural Applications | Building facades, Storefronts, Corporate interiors, Public spaces, Wayfinding signage | Digital Printing, UV Printing |

| Art Reproduction and Photography | Art prints, Photographic prints, Gallery displays, Exhibitions, Private collections | Digital Printing, Sublimation Printing |

These are just a few examples of the diverse applications of aluminum printing across industries. With its versatility, durability, and aesthetic appeal, aluminum substrate continues to be a preferred choice for creating high-quality prints that meet the diverse needs of businesses, designers, and consumers alike.

Challenges and Considerations

While aluminum substrate printing offers numerous advantages, there are also several challenges and considerations that need to be addressed:

- Cost: The initial investment for aluminum substrate printing equipment and materials can be higher compared to traditional paper printing. Additionally, the cost of aluminum sheets or foils may be higher than that of paper. Businesses need to carefully evaluate the cost-benefit ratio before transitioning to aluminum substrate printing.

- Environmental Impact: The production process of aluminum, as well as the disposal of aluminum prints, can have environmental implications. Aluminum extraction and processing require significant energy consumption and may generate greenhouse gas emissions. Additionally, aluminum prints may not be easily biodegradable, posing challenges for waste management. Efforts to minimize environmental impact through sustainable practices and recycling initiatives are essential.

- Surface Preparation: Aluminum substrate printing requires proper surface preparation to ensure optimal ink adhesion and print quality. Surface treatments such as cleaning, degreasing, and priming may be necessary to remove contaminants and create a suitable surface for printing. Failure to adequately prepare the substrate can result in poor adhesion, color inconsistency, and print defects.

- Ink Compatibility: Not all printing inks are compatible with aluminum substrates. Specialized inks formulated for use on metal surfaces may be required to achieve desired results. Businesses need to ensure compatibility between the chosen ink and the substrate to avoid issues such as adhesion failure, color shifting, and poor print quality.

- Technical Expertise: Printing on aluminum substrate requires specialized knowledge and expertise. Operators need to understand the unique properties of aluminum, as well as the intricacies of the printing process, including ink selection, substrate preparation, and equipment operation. Training and skill development are essential to ensure consistent and high-quality prints.

- Handling and Transport: Aluminum prints can be susceptible to scratching, denting, or bending during handling and transport. Proper packaging and handling procedures are necessary to protect the prints from damage and ensure their integrity. Additionally, transportation logistics need to be carefully planned to minimize the risk of physical damage during transit.

- Regulatory Compliance: Businesses engaged in aluminum substrate printing need to comply with relevant regulations and standards governing printing materials, processes, and waste management. This may include adherence to safety guidelines, environmental regulations, and product labeling requirements. Failure to comply with regulatory obligations can lead to legal consequences and reputational damage.

- Market Acceptance: While aluminum substrate printing offers unique advantages, market acceptance and demand may vary depending on industry trends, customer preferences, and competition from alternative printing methods. Businesses need to assess market demand and competition carefully and adapt their strategies accordingly to capitalize on the potential of aluminum substrate printing.

Addressing these challenges and considerations requires careful planning, investment, and ongoing commitment to quality, sustainability, and customer satisfaction. By overcoming these obstacles, businesses can unlock the full potential of aluminum substrate printing and leverage its benefits to drive growth and innovation in the printing industry.

Conclusion

Aluminum substrate printing presents a unique and exciting addition to the printer’s toolkit. Its durability, versatility, and aesthetic appeal open doors for creative expression in various applications. While there are cost and technical considerations, the potential benefits make aluminum printing a compelling option for those seeking to push the boundaries of conventional printing methods. If you are looking for the aluminium substrate supplier, please feel free to contact CHAL. The aluminium substrate for printing is a key product of CHAL, believe both the quality and service will not let you down. With advancements in technology and sustainability efforts, aluminum printing is poised to play an increasingly significant role in the future of the printing industry.