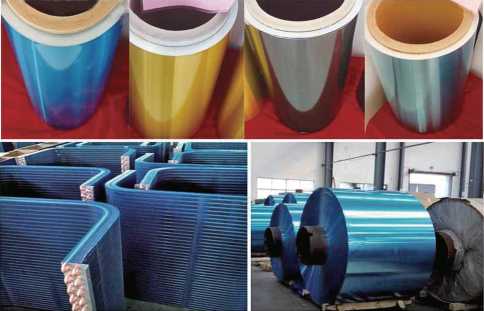

In the ever-evolving field of energy storage, the materials used in battery construction play a crucial role in determining performance, longevity, and safety. Among these materials, aluminum foil for battery applications stands out as a key component, especially in lithium-ion and next-generation batteries. As the demand for higher energy density and improved cycle life increases, more advanced variants like carbon coated aluminum foil are gaining attention. This article explores the definition, importance, and various types of battery aluminum foil, highlighting their applications across different battery technologies.

What are the Uses of Battery Aluminum Foil?

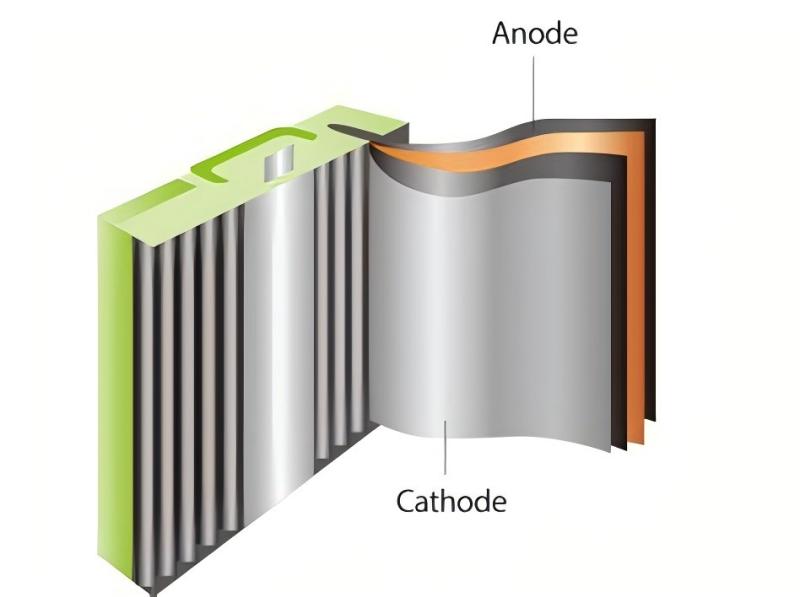

Battery aluminum foil is a specialized aluminum material designed to act as a current collector in batteries, particularly for the positive electrode (cathode). Unlike standard commercial aluminum foil, battery-grade aluminum foil must meet stringent requirements for purity, thickness, mechanical properties, and surface treatment.

In lithium-ion batteries, the aluminum foil serves multiple functions:

- Conductivity: It facilitates the flow of electrons during charge and discharge cycles.

- Structural Support: It provides a mechanical backbone for the active material layer.

- Corrosion Resistance: Its chemical stability helps prevent degradation over time.

Besides lithium-ion batteries, battery aluminum foil is also used in lithium-polymer, lithium iron phosphate (LFP), and emerging solid-state battery designs. With the expansion of electric vehicles (EVs), energy storage systems (ESS), and portable electronics, the need for high-performance aluminum foils continues to grow.

The Critical Role of Aluminum Foil in Lithium-Ion Batteries

In the context of lithium-ion batteries, aluminum foil predominantly functions as the current collector for the positive electrode, also known as the cathode. The cathode typically comprises active materials like lithium metal oxides (e.g., Lithium Cobalt Oxide – LCO, Lithium Manganese Oxide – LMO, Lithium Nickel Manganese Cobalt Oxide – NMC, Lithium Nickel Cobalt Aluminum Oxide – NCA) or lithium iron phosphate (LFP), a conductive additive (usually carbon black), and a binder material. This slurry is coated onto the aluminum foil, which then plays a vital role in several key aspects:

- Efficient Current Collection: During the discharge process, lithium ions move from the negative electrode (anode) through the electrolyte and intercalate into the cathode material. Simultaneously, electrons flow through an external circuit, generating the electrical current that powers the connected device. The aluminum foil acts as a highly conductive substrate, efficiently collecting these electrons from the cathode active material and facilitating their transport to the external circuit. Its high electrical conductivity minimizes resistive losses, ensuring maximum power delivery from the battery.

- Minimizing Internal Resistance: The internal resistance of a battery is a critical factor affecting its performance. Higher internal resistance leads to voltage drops, reduced power output, and increased heat generation. By providing a low-resistance pathway for electron flow within the cathode, the aluminum foil contributes significantly to minimizing the overall internal resistance of the battery cell. This is crucial for achieving high power density and efficient energy utilization.

- Structural Support and Mechanical Integrity: While its primary function is electrical, the aluminum foil also provides a degree of mechanical support to the cathode layer. The thin coating of active material needs a substrate to adhere to and maintain its structural integrity during the battery’s manufacturing process and subsequent charge-discharge cycles. The flexibility and strength of aluminum foil are essential for this purpose.

- Electrochemical Stability within the Cathode Potential Window: The positive electrode in a lithium-ion battery typically operates at relatively high electrochemical potentials. Aluminum exhibits good electrochemical stability within this potential window, meaning it does not readily corrode or react with the electrolyte at these voltages. This stability is crucial for the long-term performance and safety of the battery.

Types of Aluminum Foil for Battery Applications

The specific requirements of different battery applications have led to the development of various types of aluminum foil tailored for optimal performance. These variations primarily involve surface treatments and, significantly, the introduction of coatings like carbon.

1. Standard Battery Aluminum Foil

This type of aluminum foil serves as the baseline for many battery applications. Key considerations for standard battery aluminum foil include:

- Purity: High purity aluminum is preferred to minimize impurities that could potentially lead to corrosion or interfere with the electrochemical reactions. Typical purity levels are 99% or higher.

- Thickness: The thickness of the aluminum foil is a crucial parameter, influencing both the weight and the electrical resistance of the current collector. Thinner foils contribute to higher energy density (more active material per unit weight), while thicker foils offer lower electrical resistance and improved mechanical strength. Common thicknesses range from 10 to 30 micrometers.

- Surface Treatment: Surface treatments, such as roughening or chemical etching, are often applied to enhance the adhesion between the aluminum foil and the cathode coating. This improved adhesion prevents delamination and ensures good electrical contact over the battery’s lifespan.

The application fields for standard battery aluminum foil are diverse, encompassing a wide range of lithium-ion batteries used in portable electronics (smartphones, laptops), power tools, and some electric vehicle batteries, where cost-effectiveness is a significant factor.

2. Carbon Coated Aluminum Foil

This represents a significant advancement in battery current collector technology, specifically designed to address some of the limitations of standard aluminum foil and enhance battery performance in demanding applications. Carbon coated aluminum foil involves depositing a thin layer of conductive carbon material onto the surface of the aluminum foil. This carbon coating offers several key benefits:

- Improved Adhesion: The carbon layer often provides a more textured and chemically compatible surface for the adhesion of the cathode slurry compared to bare aluminum. This stronger adhesion minimizes the risk of coating delamination, especially during battery cycling and under mechanical stress.

- Reduced Contact Resistance: The interface between the active material coating and the current collector is a critical point for electron transfer. The carbon coating can significantly reduce the contact resistance at this interface, leading to improved electrical conductivity and reduced energy loss. This is particularly important at high current densities.

- Enhanced Electrochemical Performance: By facilitating better electron transport and reducing polarization within the cathode, carbon coated aluminum foil can contribute to improved rate capability (the ability to deliver high power quickly) and higher energy efficiency of the battery.

- Enhanced Corrosion Protection: In certain electrochemical environments or under specific operating conditions, aluminum can be susceptible to corrosion. The carbon coating can act as a protective barrier, preventing direct contact between the aluminum and the electrolyte, thereby enhancing the long-term stability and lifespan of the current collector and the battery as a whole.

The application fields for carbon coated aluminum foil are expanding rapidly, particularly in areas where high performance and long cycle life are paramount. These include:

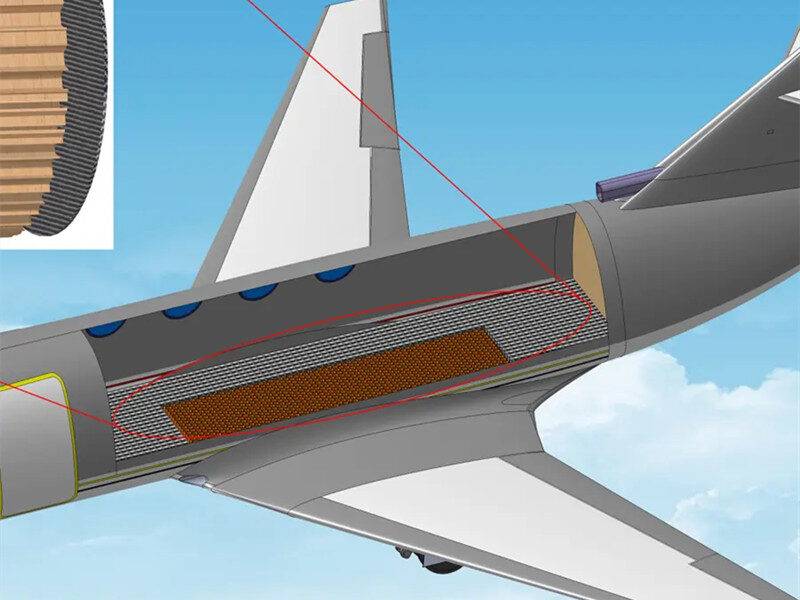

- High-Performance Electric Vehicles (EVs): The demanding power and energy requirements of EVs necessitate battery components with superior electrical conductivity and durability. Carbon coated aluminum foil is increasingly being adopted in EV batteries to enhance performance and longevity.

- High-Power Energy Storage Systems (ESS): Grid-scale energy storage and other high-power applications benefit from the reduced internal resistance and improved efficiency offered by carbon coated current collectors.

- Advanced Portable Electronics: While standard aluminum foil is still widely used, high-end smartphones, tablets, and laptops that demand optimal battery performance may also incorporate carbon coated foil.

- Batteries Operating under Extreme Conditions: Applications involving wide temperature ranges or harsh electrochemical environments can benefit from the enhanced corrosion resistance provided by the carbon coating.

The table below summarizes the key differences between standard and carbon coated aluminum foil for battery applications:

| Feature | Standard Battery Aluminum Foil | Carbon Coated Aluminum Foil |

| Surface | Bare aluminum | Aluminum with a thin carbon layer |

| Adhesion | Moderate | Improved |

| Contact Resistance | Relatively higher | Lower |

| Electrochemical Performance | Good | Enhanced |

| Corrosion Resistance | Generally good | Enhanced |

| Cost | Lower | Higher |

| Typical Applications | Portable electronics, power tools, some EVs | High-performance EVs, ESS, advanced portable electronics, extreme conditions |

In conclusion, aluminum foil plays a vital and multifaceted role in battery technology, particularly in lithium-ion batteries. While standard aluminum foil provides a cost-effective and efficient current collection solution for many applications, the advent of carbon coated aluminum foil represents a significant step forward in enhancing battery performance, durability, and safety for more demanding applications.

If you are looking for high quality battery aluminum foil, welcome to email CHAL for a quotation at any time.