The Waterproof aluminum foil tape is a very important item in many industries because of its reliable function in sealing, insulation and repair. The industrial sectors have a variety of tape applications, and these are not just confined to surface mounting components. It is also very important to consider factors such as the the overall construction of the tape, its diameter, adhesive qualities, and how much heat it can endure.

This article aims to concentrate on the three basic parameters as mentioned earlier along with additional industrial factors that need to be focused on.

What Are The Main Characteristics of Aluminum Foil Tape Waterproof?

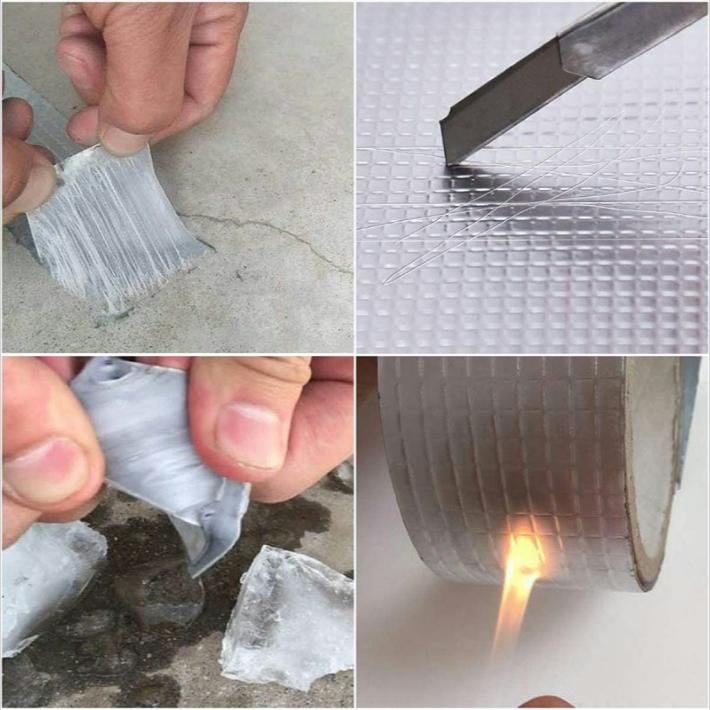

Prior to delving into the elements of choosing the right one, it is important to grasp the notion of waterproof aluminum foil tape and its parts. Simply put, the tape aims to form a mechanical and sturdy seal that is resistant to moisture permeation.

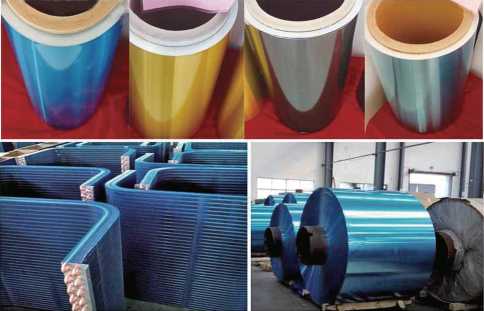

The majority of waterproof aluminum foil tapes are manufactured with specific multilayered designs where each layer contributes to its functionality:

| Layer | Material | Purpose |

| Aluminum Foil | Metal | Provides waterproofing, durability, and thermal resistance. |

| Adhesive Layer | Acrylic, rubber, or silicone | Ensures strong adhesion to surfaces, even under extreme conditions. |

| Release Liner | Treated paper or film | Protects the adhesive before application, ensuring ease of use. |

Why These Properties Matter for Industrial Applications?

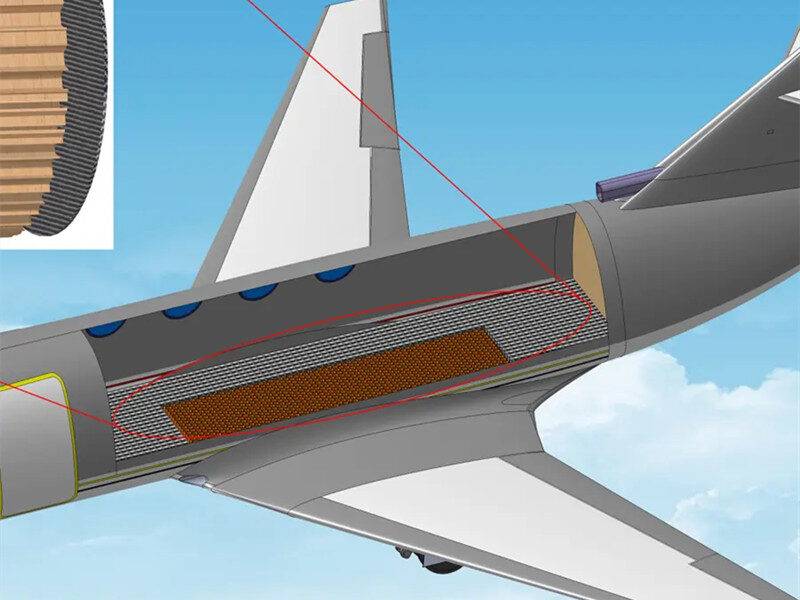

The properties of materials often undergo extensive evaluation for industrial applications. Both precision and accuracy are especially prominent in industrial requirements. Industrial aluminum foil tape, for instance, must undergo rigorous testing and be reliable when used for critical insulation in devices. This is because, like all industrial machinery, devices face unique pressures.

Every machine undergoes harsh environmental impacts, including vibrations, chemicals, abrasions, and extreme temperatures. The tape must maintain bonds and adhesion during fluctuating temperatures. A weak bond, such as foils that are brittle or weak, will damage machinery by impairing insulation and creating air and moisture leaks.

Machines that are rugged and reliable significantly minimize operational costs. To achieve that, bespoke machinery must not undergo significant structural wear or damage from chemicals, UV light, or abrasions. This “set and forget” strategy aids in reducing the need for constant equipment servicing, reducing repair downtime and machine maintenance.

Operational requirements of machinery such as HVAC systems and marine devices commonly face stringent operational boundaries and regulations. Operational boundaries such as zero moisture exposure, specific fire ratings, and stringent compliance parameters. Operational safety while using machinery also must not be undermined, meaning critical components such as tape cannot impact stability.

The main components of aluminum foil tape, including waterproofing, thermal resistance, durability, and adhesion summarize the effectiveness and reliability needed. Further details and application parameters need to be explored for enhanced machine performance and reliability.

Parameter 1: Thickness – The Basis of Structural Endurance and Safeguarding

While examining waterproof aluminum foil tapes, one of the detectable features is thickness. This is definitely not just maximizing the material utilized, thickness is crucial in determines the tapes strength and protective capabilities.

What is the Tape Thickness?

Tape thickness is the measurement dimensions of the foil and the adhesive layer that encompasses it. It is often measured in “mils” and microns. “3 mil” is equivalent to 0.003 inches.

How Thickness Impacts Performance

The above mentioned components are needed to be understood in regards to the aluminum foil and its functionalities:

- Durability and Puncture Resistance: Tapes work better when they are thicker. Resistance to abrasions, tears and punctures are more with robust tapes. These are extremely useful in areas that face stress and are subject to damage. Consider the case of HVAC duct vessels positioned in a factory floor. Having a thicker tape is much more useful for resisting damage from bump and scrape accidents.

- Conformability vs. Rigidity: Generally, thinner tapes exhibit greater conformability. These tapes are easier to wrap around irregular shapes, corners, and tight curves without lifting or wrinkling. While stronger, thicker tapes may be less flexible and more difficult to apply smoothly to complex contours.

- Thermal Insulation Properties: Although aluminum foil is an excellent thermal reflector, a thicker foil can provide slightly better protection against radiant heat transfer. More importantly, thicker and more rigid tapes can better maintain the thermal insulation jacket’s integrity, ensuring no air gaps that would compromise thermal performance exist.

- Moisture Vapor Barrier Performance: Waterproofing relies primarily on the foil’s integrity. A thicker foil is more effective at reducing moisture vapor transmission, which is important to avoid condensation, corrosion, and mold growth in insulated systems.

Thickness Recommendations for Different Applications

The optimal tape thickness is always application-dependent. Here are some examples:

| Application Type | Recommended Thickness (Mils) | Key Performance Drivers |

| Light-Duty Sealing | 2.0 – 3.0 mil | General patching, temporary fixes, very light-duty HVAC sealing. |

| General Purpose HVAC & Duct Sealing | 3.0 – 5.0 mil | Standard ductwork, pipe insulation, less demanding sealing. |

| Heavy-Duty HVAC & Industrial Sealing | 5.0 – 7.0 mil | High-pressure ductwork, outdoor applications, moderate abrasion areas. |

| High-Performance/Critical Barrier | 7.0 – 10.0+ mil | Roofing flashing, marine use, high-traffic areas, critical moisture barriers, chemical resistance. |

To summarize, do not underspecify thickness just to save a few cents. The thinner and thicker tape difference, while initially seeming to lead to cost savings, could result in greater expenses tape failure, energy loss, moisture damage, and reapplied work. Select a thickness that meets the rigors of and confidently endures the physical and environmental challenges of your industrial work.

Parameter 2: Viscosity (Adhesive Strength) – The Critical Determinant of Adhesive Durability

While the foil serves as a protective covering, the tape adheres to the substrate because of the adhesive and the tape is a seal which adheres over time. Adhesive adhesive stickiness, viscosity, etc, is very important. The general rule is that the stickier the tape, the better and more reliable the tape is, especially in harsh environments.

What Does “Stickiness” and Flow Properties Refer to For Adhesives?

Viscosity is a term used to describe the relative thickness of a liquid and its flow characteristics. With adhesives, viscosity refers to the adhesives wetting and spreading behavior on a surface as well as adhesive strength. In addition to tack (the feel and stickiness of the adhesive), we are interested in adhesive bond durability across time and exposure to different bond line stresses.

Viscosity-related adhesive characteristics are as follows:

- Initial Tack: This refers to the immediate grab of the adhesive upon contact. This is most useful for aggressive bonding in high contact, difficult surfaces, or overhead where sagging is an issue.

- Adhesion to Various Substrates: Different industrial surfaces such as smooth metals, galvanized steels, concrete, plastics, and painted surfaces have different surface energies and textures. It is critical that the adhesive be designed to bond to the specific surfaces that it will interface with.

- Shear Strength: This is the ability to resist “cutting” or sliding forces that attempt to move the adhesive perpendicular to the bond surface. High shear strength is essential for tape that is subjected to sustained pulling or pushing forces, such as heavy insulation or constant vibration.

- Peel Adhesion: This criterion measures the force exerted in removing tape from a surface at a 90 or 180 degree angle. High peel adhesion demonstrates the bond is stationary and enduring, thus resisting lifting at the edge, a failure mode of many bonds.

Types of Adhesives Commonly Used

The adhesive chemistries used in industrial-grade aluminum foil tapes are:

- Acrylic Adhesives: These are known for being durable in comparison to other adhesives, with a strong bond to UV Radiation, extreme temperatures, and a wide variety of chemicals. The bond tends to be stronger over time and longer durability adhesives are preferred in outdoor and longer life span applications.

- Rubber-Based Adhesives: These adhesives are known for a strong initial bond which tend to drop in temperature resistance, UV stability, and chemical resistance in comparison to acrylics. These types of adhesives work best in areas where bond strength is a priority. Specialized versions of these are known to be synthetic rubber and have shown to provide better results.

Matching Viscosity to Application and Surface

- Understanding your adhesive needs for bond strength involves a mix of geometry of the surfaces to be joined.

- Consider The Surface: Does it have an even texture? Is it non-porous? Is it clean? An option such as a high tack adhesive is best for rough surfaces that are clean and intact surfaces where standard adhesives may be a better fit.

- Humidity, oil, grease, or cleaning chemicals actively working against the tape will hinder exposure. The elements mentioned will cause the adhesive to weaken without considerable resistance.

- If the sealed components undergo expansion, contraction, or vibration, the adhesive needs adequate elasticity to avoid failure or creep. The adhesive should possess enough elasticity or shear strength to avoid creep or failure.

Here are some common choices:

| Industrial Application / Surface Type | Key Performance Demands | Suitable Adhesive Type(s) |

| Outdoor HVAC Ducts & Insulation | High UV exposure, wide temperature fluctuations, long-term durability. | Acrylic (High-Performance) |

| Indoor Standard Duct Sealing | Good initial tack, conformability to ductwork, general adhesion. | Rubber-based (Synthetic or Natural), Standard Acrylic |

| Pipe Insulation Jacketing | Secure bond over long runs, resistance to thermal expansion/contraction. | Acrylic (High Shear Strength) |

| Rough/Textured Surfaces | Ability to “wet out” and bond to uneven substrates (e.g., concrete, stucco, rough metal). | Rubber-based (High Tack), Modified Acrylic |

| Smooth, Low-Energy Surfaces | Bonding to plastics (e.g., PVC, polyethylene), painted surfaces, powder coatings. | Acrylic (High Peel Adhesion), Specialty Adhesives |

| Marine & High-Humidity Areas | Constant moisture exposure, potential for salt spray, chemical resistance. | Acrylic (Waterproof/Marine Grade), Butyl-based |

| Critical Seals/Long-Term Assets | Maximum reliability, minimal maintenance, extended service life. | Acrylic (Premium Grade, cross-linked) |

| Quick Repairs / Temporary Sealing | Fast application, immediate bond, less concern for extreme longevity. | Rubber-based (High Initial Tack) |

| Vibrating Equipment | Resistance to dynamic forces, maintaining bond despite movement. | Acrylic (High Shear Strength, Flexible) |

Selecting the right adhesive viscosity ensures that your waterproof aluminum foil tape isn’t just “stuck on” but truly “bonded,” providing a reliable and lasting seal where it’s needed most.

Parameter 3: Temperature Resistance: Withstanding the Extremes

Many industrial sites constantly deal with temperature extremes. A hot pipe, for instance, is only one of the temperature related trials. Other mechanisms like storage units, which operate at freezing temperatures, pose the risk of using tape which would not operate reliably under harsh conditions. Withstanding the extremes is not simply measured in tape melting. Temperature failure mechanisms of a tape could be complex, including the loss of reliable seal formation or grip weakening.

Understanding Temperature Ranges

While examining temperature resistance, evaluating a tape temperature resistance, two key ranges are critical:

Service Temperature/Operating Temperature: This is the continuous temperature range within which the tape in question is engineered to perform optimally throughout its lifecycle. A tape for instance could have a service temperature range of -20°F to 250°F which would translate to -29°C to 121°C. This means it would reliably function within the temperature limits.

Application Temperature: This describes the temperature limits of the surface and the environment during the tape’s installation. Operational temperature limits may not guarantee an adhesive’s effectiveness when applied at lower or higher temperature extremes. Take, for example, tape’s application temperature range of 40 – 150 F (4 – 65 C). This means the tape should not be applied to surfaces outside these temperatures.

Effects of Temperature on Performance of Tape

Both extremes and fluctuations of temperature have an effect on aluminum foil as well as the adhesive layer, but more importantly the adhesive layer.

Aging of Adhesive:

Excessively high temperatures. Adhesive materials, in relation to temperature elevation, are subjected to softening, loss of cohesive strength (leading to “cold flow”), or rupture of chemical bonds, resultant in shedding of adhesion and lifting/peeling of the tape.

Excessively low temperatures. Cold temperature extremes can make adhesive materials brittle, so they can no longer turn and retain their adhesive character. Cold can make the adhesive layer weak and tacky, losing the ability to grab surfaces and achieve an airtight seal.

Foil Integrity: While somewhat more rare than problems with the adhesive, extreme temperatures are likely to have an effect on the aluminum foil’s strength and reliability. In addition to that, severe thermal cycling may lead to the expansion and contraction of the underlying materials, which is detrimental to the tape. The tape has to have enough softness and elasticity so that, while under stress/temperature, it can bend without the occurrence of delamination or tearing.

Selecting for Specific Temperature Environments

Matching the tape’s temperature resistance to your application’s environment is non-negotiable:

| Application Environment | Typical Temperature Range | Key Considerations |

| Standard HVAC Ducts (Indoor) | 40°F to 150°F (4°C to 65°C) | Most standard industrial aluminum tapes will suffice. Focus on good adhesive for typical duct materials and proper application temperature. |

| Outdoor HVAC/Insulation | -20°F to 180°F (-29°C to 82°C) | Requires tapes with excellent UV stability and a broad service temperature range to handle seasonal fluctuations. Acrylic adhesives are generally preferred here. |

| Cold Storage / Refrigeration | -40°F to 30°F (-40°C to -1°C) | Needs tapes with adhesives specifically formulated to remain flexible and tacky at very low temperatures. Pay attention to both application and service temperature ratings. |

| High-Temperature Systems | 200°F to 350°F+ (93°C to 177°C+) | Crucial for applications near boilers, ovens, exhaust systems, or hot pipes. Look for tapes explicitly rated for high temperatures, often utilizing specialized high-performance acrylic or silicone-based adhesives. Ensure both foil and adhesive can withstand the heat. |

| Cycling Temperatures | Significant fluctuations | Requires tapes with excellent flexibility and adhesive resilience to repeated expansion and contraction of the underlying materials. High-performance acrylics are usually best. |

Overlooking temperature resistance can lead to catastrophic failure. A tape that becomes brittle in the cold will crack, breaking the seal. One that softens in the heat will creep and peel, leading to leaks and efficiency losses. Always specify a tape whose temperature ratings exceed the expected minimum and maximum conditions of your industrial application.

Additional Considerations in Regards to Industrial Applications

Though viscosity, thickness, and temperature resistance are the primary concerns, selection of waterproof aluminum foil tape for industrial applications requires consideration of some other factors as well. These industrial requirements are critical in determining the performance and durability of the tape, as well as the industrial compliance.

- UV Resistance: For outdoor industrial uses, as well as indoors but areas where the sunlight is considerable, UV resistance becomes extremely important. UV radiation is known to damage the bonds of adhesives making them flaky and brittle, and therefore, causing the tape to fail much sooner than its intended lifespan. Good UV resistance means good durability for adhesive tapes, and the ability to not undergo brittle, yellowing, and cracking staling after years of sunlight exposure.

- Flame Resistance / Fire Rating: Fire safety is particularly of high concern in industrial settings like HVAC systems and construction materials. The tape should not have a significant adverse impact to fire spread and bound smoke generation, as well as not be hugely hazardous during emergency situations. Look for a Fire Rating UL 723, (ASTM E84) for surface burning characterists, and flame spread and smoke developed, to not be a significant hazard fire and smoke.

- Moisture and Chemical Resistance (Beyond Water): While industrial tapes may be labeled as “waterproof,” industrial environments are usually exposed to various chemicals. Consider if the tape will encounter oils, degreasers, solvents, weak acids, or weak bases. Some tapes are engineered with chemically resistant adhesive and foil coatings to withstand certain exposures without losing structural integrity.

- Conformability and Flexibility: It is critical for tape application that the tape adheres to irregular surface geometry, edges and curves smoothly without any lifting or wrinkles for an airtight seal. It is especially critical that a highly conformable tape is easy to apply on more intricate geometries, such as pipe elbows or textured equipment housings. Often, this is associated with the adhesive flexibility the foil’s thickness.

- Vapor Barrier Performance (MVTR): For insulation applications, the tape’s performance as a moisture vapor barrier is critical. This is measured through the Moisture Vapor Transmission Rate, or water vapor transmission rate (MVTR). A low MVTR provides a stronger barrier, reducing the potential for condensation within the insulation and subsequently corrosion and mold on the structural components.

- Ease of Application: Although this factor may not fall under performance characteristics, the application process affects the overall labor costs and the quality of the installation. Consider if the tape is linerless (which speeds application or release liner) or cuts to enable precise positioning, how the tape tears or cuts, and whether it tends to curl and wrinkle during handling. Faulty tape application will greatly increase the chances of the seals failing in the structure.

- Industry Standards and Certifications: It is essential to always check whether the tape satisfies industry regulations and certifications. This may include UL listings for HVAC, their UL certifications, and ASTM specifications for the performance of the adhesive in question, or building codes. Compliance assures the product has gone through rigorous tests and meets performance benchmarks for critical tests of the product regarding safety and reliability.

Considering the factors of thickness, viscosity, and temperature resistance, combining these elements will enable the user to select the most suitable waterproof aluminum foil tape for many challenging industrial applications. Such rigorous evaluation assures that the tape will not only perform its intended function and meets the industrial expectations of safety, reliability, and efficiency for the infrastructure.