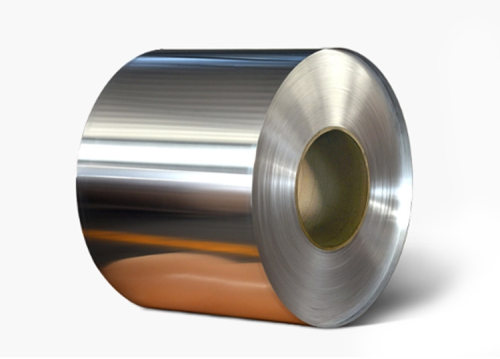

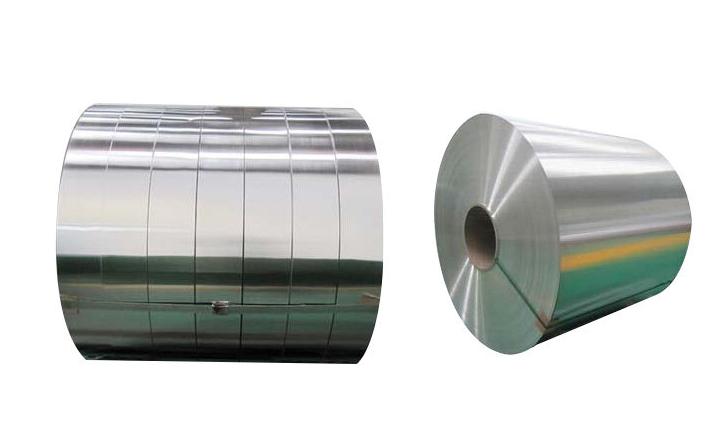

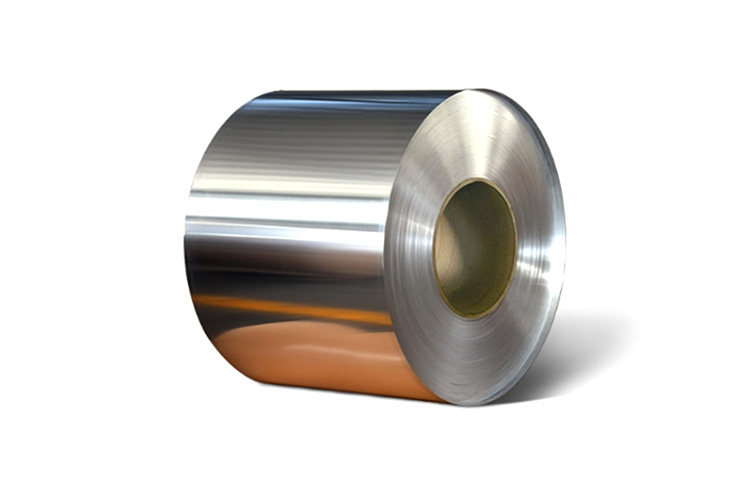

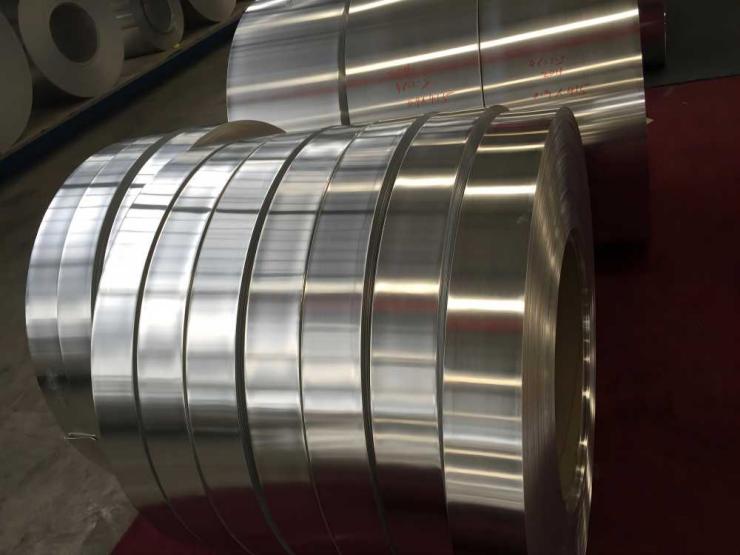

Aluminum strip rolls play a vital role in modern car manufacturing. These long, continuous coils of aluminum offer a unique combination of properties that make them ideal for a variety of automotive applications. This article will explore the properties of aluminum strip rolls, the advantages they bring to car manufacturing, specific applications where they are used, common grades employed, and why they are a key material in today’s vehicles.

Properties of Aluminum Strip Rolls in Auto

Aluminum strip rolls are commonly used in various automotive applications due to their advantageous properties. Some of the key properties of aluminum strip rolls in auto applications include:

- Lightweight: Aluminum is significantly lighter than steel, which helps reduce the overall weight of vehicles. This contributes to improved fuel efficiency and better handling.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer on its surface, which enhances its resistance to corrosion. This property is crucial for automotive applications, as vehicles are exposed to various environmental conditions.

- Conductivity: Aluminum is an excellent conductor of electricity, making it suitable for electrical wiring and components in vehicles.

- Thermal Conductivity: Aluminum has good thermal conductivity, allowing it to efficiently dissipate heat. This property is essential for components such as radiators and heat exchangers in automotive cooling systems.

- Formability: Aluminum can be easily formed into various shapes and sizes, making it adaptable to different automotive designs and manufacturing processes.

- Recyclability: Aluminum is highly recyclable, which aligns with the automotive industry’s increasing focus on sustainability and environmental responsibility.

- Strength-to-Weight Ratio: Although aluminum is not as strong as steel, it offers a favorable strength-to-weight ratio. This property allows manufacturers to design lightweight yet structurally sound components.

- Acoustic Damping: Aluminum can help reduce noise and vibration within the vehicle, improving overall comfort for passengers.

- Aesthetic Appeal: Aluminum’s appearance can enhance the visual appeal of automotive components, contributing to the overall design aesthetics of vehicles.

- Compatibility with Joining Methods: Aluminum can be welded, riveted, or bonded using various techniques, facilitating assembly processes in automotive manufacturing.

These properties collectively make aluminum strip rolls a preferred material choice for a wide range of automotive applications, including body panels, chassis components, heat exchangers, and structural reinforcements.

Specific Applications of Aluminum Strip Rolls in Automotive

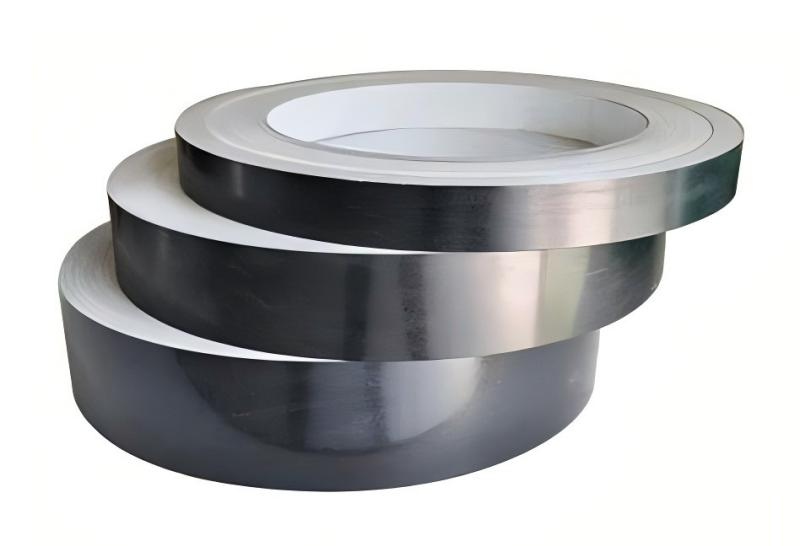

Aluminum strip rolls find numerous specific applications in the automotive industry due to their advantageous properties. Some common applications include:

- Body Panels: Aluminum strip rolls are used to manufacture body panels such as hoods, doors, fenders, and trunk lids. Their lightweight nature helps reduce the overall weight of the vehicle, contributing to improved fuel efficiency and performance.

- Heat Exchangers: Aluminum strip rolls are utilized in the production of heat exchangers, including radiators, intercoolers, and condensers. Their high thermal conductivity facilitates efficient heat transfer, essential for cooling systems in engines and air conditioning units.

- Chassis Components: Certain chassis components, such as subframes, suspension parts, and crossmembers, are often constructed using aluminum strip rolls. These components benefit from aluminum’s strength-to-weight ratio, contributing to enhanced vehicle handling and structural integrity.

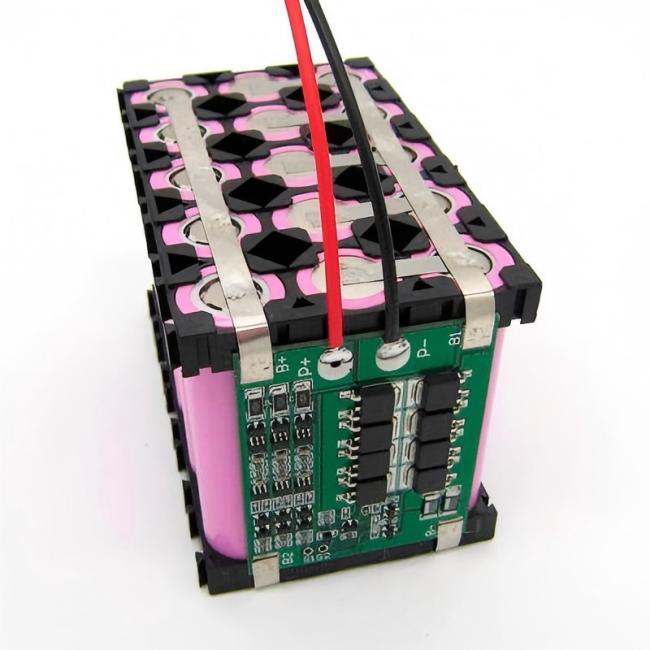

- Battery Enclosures: With the rise of electric vehicles (EVs), aluminum strip rolls are increasingly used in the construction of battery enclosures. Aluminum’s lightweight and corrosion-resistant properties make it an ideal material for protecting and housing EV battery packs.

- Structural Reinforcements: Aluminum strip rolls are employed in the fabrication of structural reinforcements, including pillars, beams, and crash structures. These components provide added safety and rigidity to the vehicle’s frame while minimizing weight.

- Interior/Exterior Trim and Accents: Aluminum strip rolls are utilized in interior trim and accents, such as dashboard trim, door handles, and decorative panels. Their aesthetic appeal and ability to be easily formed into intricate shapes enhance the interior design of vehicles. Aluminum strip rolls are employed in exterior trim and accents, such as window frames, grilles, and roof rails. These components enhance the vehicle’s appearance while benefiting from aluminum’s corrosion resistance and durability.

- Electrical Wiring and Connectors: Aluminum strip rolls are used in the manufacturing of electrical wiring and connectors within vehicles. Their conductivity and lightweight nature make them suitable for transmitting electrical signals efficiently.

- Wheel Rims: Aluminum strip rolls are commonly used to produce lightweight alloy wheel rims. These rims offer improved performance, such as better handling, braking, and fuel efficiency, compared to traditional steel rims.

These specific applications demonstrate the versatility and importance of aluminum strip rolls in the automotive industry, contributing to advancements in vehicle design, performance, and sustainability.

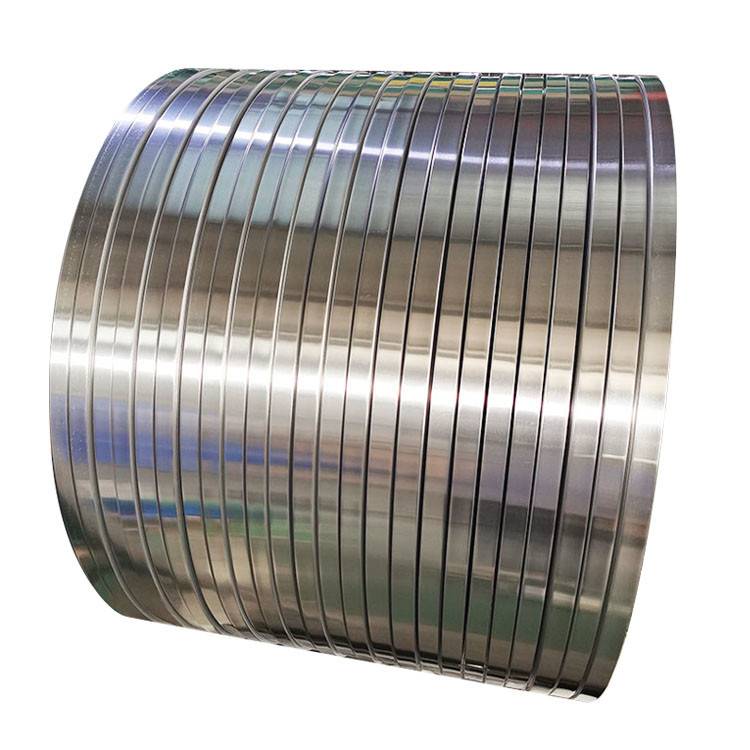

Common Grades of Aluminum Strip Rolls Used in Auto

Several common grades of aluminum strip rolls are used in automotive applications, each chosen for its specific properties and suitability for different components. Some of the most prevalent grades include:

| Grade Series | Common Alloys | Typical Automotive Applications |

| 1xxx Series | 1100, 1050 | Body panels, trim, interior components |

| 3xxx Series | 3003, 3105 | Heat exchangers (e.g., radiators) |

| 5xxx Series | 5052, 5754 | Structural components (e.g., chassis parts, body reinforcements, floor panels) |

| 6xxx Series | 6061 | Structural components (e.g., subframes, suspension parts, crash structures) |

| 7xxx Series | 7075 | High-performance components (e.g., suspension parts, alloy wheel rims) |

| 8xxx Series (Aluminum-Lithium Alloys) | Varies | Weight-critical applications (not widely used in automotive) |

| 5xxx/6xxx Hybrid Structures | Varies | Components optimized for weight reduction, strength, and formability |

Each of these grades possesses unique characteristics that make them suitable for different automotive applications, allowing manufacturers to tailor material selection to meet performance, cost, and design requirements.

Conclusion

In conclusion, the utilization of aluminum strip rolls in automotive manufacturing represents a transformative shift towards lightweight, sustainable, and high-performance vehicles. With its exceptional properties, numerous advantages, diverse applications, and availability in various grades, aluminum strip rolls have become indispensable in shaping the future of the automotive industry. As technological advancements continue to drive innovation, aluminum strip rolls will undoubtedly play a central role in the development of next-generation vehicles, ushering in an era of unprecedented efficiency, safety, and environmental consciousness.