When it comes to finishing touches in your tiling project, the edges play a crucial role. Not only do they impact the overall aesthetics, but they also offer protection and functionality. Two common options for edging are aluminum tile trim and aluminum strip. While both utilize aluminum, they serve distinct purposes and offer different advantages. This article delves into the details of each material, their applications, and how to choose the right one for your needs.

What is Tile Trim?

Tile trim, also known as tile edging or tile profile, is a specifically designed component used to finish the exposed edges of a tiled surface. It comes in various shapes, sizes, and materials, with aluminum being a popular choice due to its affordability, durability, and versatility. Tile trim serves several key functions:

- Protection: It safeguards the exposed edges of tiles from chipping, cracking, or damage caused by everyday wear and tear, particularly in high-traffic areas.

- Finished Look: Tile trim creates a clean and polished appearance by concealing the raw edges of the tiles, contributing to a professional and aesthetically pleasing finished product.

- Imperfection Coverage: Uneven tile cuts or slight gaps between tiles can be effectively masked by tile trim, ensuring a uniform and visually seamless outcome.

- Movement Accommodation: In certain applications, such as transitions between different flooring materials, tile trim can accommodate slight movement between surfaces, preventing cracking or separation.

Types of Aluminum Tile Trim

Aluminum tile trim comes in a variety of shapes, each designed to address specific needs and enhance the visual appeal of your tiled surfaces. Here’s a breakdown of common aluminum tile trim profiles:

- Square Edge: This profile features a crisp 90-degree angle, creating a clean and modern look. It’s ideal for providing a straight, finished edge to wall tiles and for transitions between tiles and other flooring materials of equal height. The square edge sits flush against the tile for a seamless look.

- Round Edge (Bullnose): This profile offers a smooth, curved edge, adding a softer touch compared to the square edge. It’s particularly suitable for countertops, backsplashes, and curved tile installations. The rounded edge provides a comfortable, finished look and eliminates any sharp corners that might be a concern, especially around areas like countertops.

- Schluter Jolly (Brand Specific): Schluter Jolly is a brand that offers a variety of L-shaped profiles with a rounded edge on the visible side. This design combines the functionality of a square edge (protecting the tile) with the softer aesthetics of a bullnose. Schluter Jolly profiles are versatile and can be used in various applications due to their ability to offer both protection and a finished look.

- Corner Pieces: For a clean and protected finish at inside and outside corners, specific L-shaped or U-shaped tile trim profiles are available. These corner pieces are designed to fit snugly into the corner, ensuring complete coverage and protection for the tile edges at these critical junctions. Corner pieces prevent chipping or damage from occurring in these vulnerable areas.

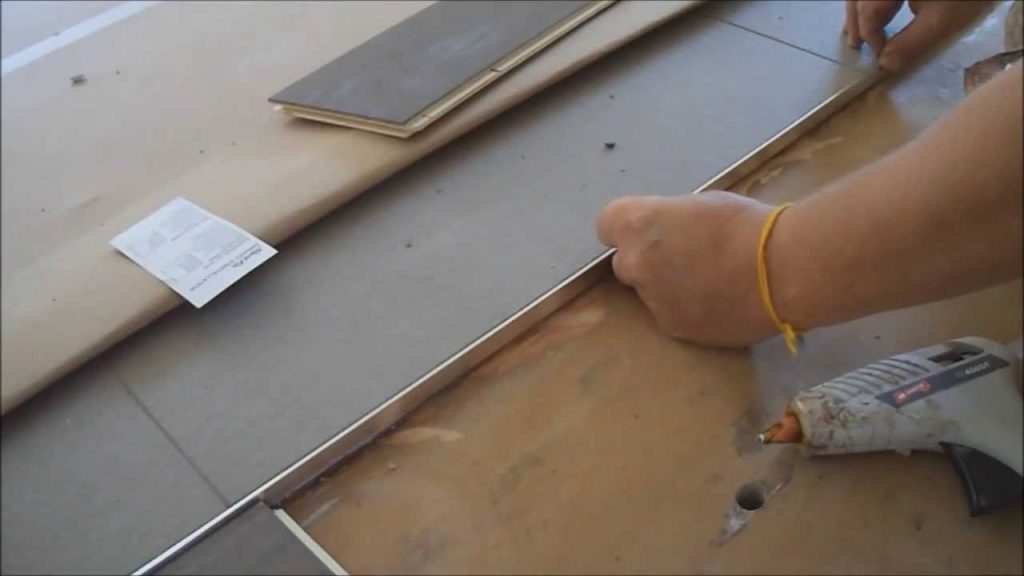

Installation of Aluminum Tile Trim: Step-by-Step Guide

Installing aluminum tile trim is a straightforward process that can be completed with the proper tools and materials. Here’s a step-by-step guide to help you achieve a professional-looking finish:

- Preparation: Before starting, ensure the tile surface is clean, level, and free of any debris. Dirt, dust, or uneven surfaces can hinder proper adhesion of the tile trim.

- Selection: Choose the appropriate tile trim profile based on your application and desired aesthetics. Consider the type of tile edge (straight, corner), location (wall, floor), and the overall look you want to achieve (square, rounded).

- Cutting: Using tin snips for thinner profiles or a hacksaw for thicker profiles, carefully cut the tile trim to the desired length. Ensure straight and clean cuts for a professional finish.

- Adhesive Application: Depending on the specific product you choose, the tile trim might have a pre-attached adhesive backing. If not, you’ll need to use a thin-set mortar or construction adhesive to secure the trim in place. Apply the adhesive according to the manufacturer’s instructions.

- Positioning: Carefully position the cut tile trim along the edge of the tile, ensuring a straight and level alignment. Press the trim firmly against the tile to ensure good adhesion. Use a level to confirm proper alignment.

- Grouting (Optional): In some cases, grouting the small gap between the tile and the trim might be necessary for a complete and finished look. This step is typically done after the adhesive has cured completely. Use a grout color that complements your tiles for a cohesive appearance.

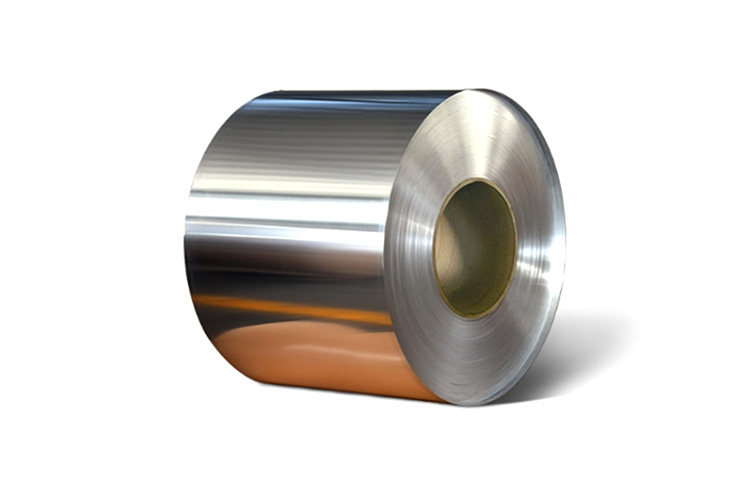

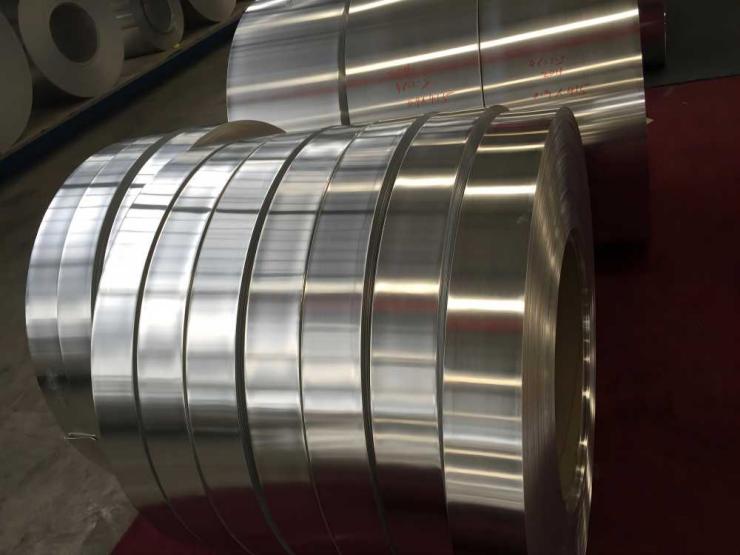

What is an Aluminum Strip?

An aluminum strip is a simple and practical material consisting of a long, flat piece of aluminum. It comes in various widths and thicknesses to suit a wide range of applications. Due to its affordability and workability, aluminum strip is a popular choice for various construction and DIY projects. However, it’s important to understand that, unlike tile trim, the aluminum strip isn’t specifically designed for use with tiles.

Differences Between Aluminum Tile Trim and Aluminum Strip

While both aluminum tile trim and aluminum strip share aluminum as their core material, there are significant distinctions between the two:

- Purpose: Aluminum tile trim has a specialized function. It’s designed to provide a finished look and protect the exposed edges of tiled surfaces. Conversely, aluminum strip is a general-purpose material with a broader range of uses beyond tiles. It can be used for framing, flashing, ductwork, and various other construction or repair applications.

- Profile: Aluminum tile trim comes in a variety of pre-defined shapes. These profiles, such as square edge, round edge (bullnose), or corner pieces, are specifically designed to integrate seamlessly with tiles. They offer features like a 90-degree angle for straight edges, a rounded edge for a softer look, or L-shaped profiles for perfect corner finishing. An aluminum strip, on the other hand, is a flat piece without any pre-defined shape. It may require additional bending, shaping, or cutting to achieve the desired form for a specific application.

- Aesthetics: Aluminum tile trim boasts a finished appearance with smooth edges and potentially decorative profiles that complement the tiles. They are designed to create a visually appealing and polished look. In contrast, the aluminum strip has a plain, flat profile that might require additional finishing touches, such as sanding or painting, to achieve a more aesthetically pleasing result, especially for applications where appearance is a factor.

Can We Use Aluminum Strips for Tile Projects?

In some instances, aluminum strips might be a temporary or budget-conscious alternative for tile edging. However, it’s important to consider the limitations:

- DIY Edging: With proper cutting and finishing (e.g., sanding the edges), aluminum strips can be used for DIY edging on walls, particularly for non-critical areas. However, achieving a professional-looking finish might be more challenging compared to using dedicated tile trim.

- Temporary Edging: In situations where a temporary edging solution is needed before permanent tile trim is installed, an aluminum strip can be a viable option. This might be useful during the construction phase to protect the tile edges from damage or for open-air exhibits where permanent trim isn’t necessary. However, it’s important to remember that aluminum strips won’t offer the same level of protection or aesthetics as dedicated tile trim.

Choosing Between Aluminum Tile Trim and Aluminum Strip

The decision between aluminum tile trim and aluminum strip hinges on several factors:

- Application: Consider the location of the tile edging. For high-traffic areas, corners, or applications requiring a polished look, aluminum tile trim is the superior choice due to its durability and finished profiles.

- Desired Finish: If a clean, professional aesthetic is paramount, aluminum tile trim offers a wider variety of profiles and a more polished look compared to the potentially unfinished appearance of aluminum strips.

- Budget: Aluminum strips are generally less expensive than aluminum tile trim. However, consider the additional time and effort required for cutting, shaping, and finishing the aluminum strip to achieve the desired outcome.

When to Choose Aluminum Tile Trim

Here are some scenarios where aluminum tile trim is the ideal choice:

- High-Traffic Areas: For areas experiencing frequent foot traffic, such as kitchen floors, bathroom floors, or entryways, aluminum tile trim provides superior edge protection and prevents chipping or cracking of the tiles.

- Corners: Inside and outside corners require specific L-shaped or U-shaped profiles to ensure a seamless and protected finish. Tile trim offers these specialized profiles for a proper fit.

- Desired Aesthetics: When a clean, finished look is essential, aluminum tile trim comes in various profiles that complement the tiles and elevate the overall aesthetics of the project.

- Transitions: When transitioning between different flooring materials, tile trim can accommodate slight movement and prevent cracking or separation at the junction.

When Using Aluminum Strip Might Be an Option

While not ideal for all situations, the aluminum strip can be a suitable alternative in specific scenarios:

- DIY Edging (Low-Traffic Walls): For non-critical areas on walls with minimal foot traffic, using aluminum strips for DIY edging might be a budget-friendly option. However, achieving a professional look requires careful cutting, smoothing of edges, and potentially painting for a finished appearance.

- Temporary Edging: In situations where temporary protection for tile edges is needed during construction or before permanent trim installation, aluminum strips can serve as a placeholder. Remember to remove it before installing the permanent tile trim.

Conclusion

Both aluminum tile trim and aluminum strip have their uses. Aluminum tile trim is the clear choice for professional-looking, long-lasting edging solutions, especially in high-traffic areas, corners, or when aesthetics are a priority. However, for specific DIY projects with low traffic or temporary edging needs, aluminum strips can be a budget-conscious alternative, albeit with limitations in terms of aesthetics and protection. By understanding the strengths and weaknesses of each material, you can make an informed decision that best suits your project requirements and budget.