Aluminum strips are widely used in various industries due to their lightweight nature, high strength-to-weight ratio, and excellent corrosion resistance. However, to further enhance their performance and protect them from environmental factors, surface treatments, and coatings are often applied. These treatments not only improve the aesthetics of the aluminum strips but also provide additional functionalities such as increased durability, corrosion resistance, and customization options. In this article, we will delve into the surface treatment steps involved in enhancing aluminum strip properties.

The Aluminum Strip Surface Treatment Steps are as follows:

The First step: Preparation

The first step in aluminum strip surface treatment is proper preparation. This involves thoroughly cleaning the surface to remove any dirt, oils, or contaminants that may interfere with the treatment process. The cleaning method may include degreasing, alkaline cleaning, or mechanical cleaning, depending on the specific requirements. After cleaning, the surface may undergo etching to promote adhesion and create a roughened texture for better coating or treatment penetration.

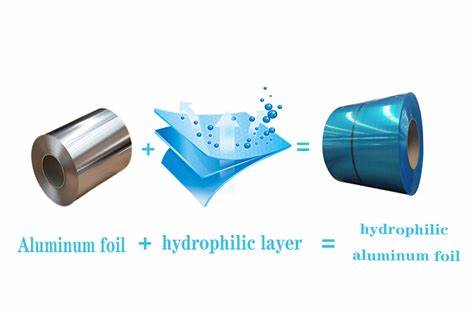

The Second Step: Application of Treatment or Coating

Once the aluminum strip surface is properly prepared, the next step is the application of the desired treatment or coating. Various methods can be employed, depending on the type of treatment. For example, anodizing, which involves creating an oxide layer on the surface, can be achieved through an electrochemical process. The aluminum strip serves as the anode in an electrolyte bath, and a direct current is applied to promote the formation of the oxide layer. On the other hand, painting and powder coating can be applied through spraying, electrostatic deposition, or dipping methods. The coating material is evenly applied to the surface, ensuring proper coverage and thickness.

The Third Step: Curing or Drying

After the treatment or coating is applied, the aluminum strips often require curing or drying. This step is crucial for the treatment or coating to fully develop its desired properties. In the case of painting, for instance, the coated strips may be subjected to a thermal curing process in which the coated surface is heated to a specific temperature to promote cross-linking and polymerization of the paint. Powder coatings, on the other hand, go through a curing process where the coated strips are heated in an oven to melt and fuse the powder particles, forming a continuous protective layer. Drying time and conditions may vary depending on the specific treatment or coating applied.

These surface treatment steps play a vital role in enhancing the properties and performance of aluminum strips. They provide numerous benefits, such as improved corrosion resistance, increased durability, and enhanced aesthetics. Anodizing creates a hard, protective oxide layer that increases resistance to corrosion and wear. The thickness of the anodized layer can be controlled to achieve desired properties such as color options or improved paint adhesion. Painting and powder coating offer a wide range of color choices, finishes, and textures, while providing protection against environmental factors. Cladding and laminating processes allow for the application of different materials, such as stainless steel or PVC, to provide additional functionalities and aesthetic appeal.

When considering surface treatments and coatings for aluminum strips, it is essential to take into account several factors. Application requirements and specifications, environmental conditions, and budget constraints should all be considered. The specific industry or application of the aluminum strips may dictate the most suitable treatment or coating. Additionally, the expertise and reputation of suppliers and manufacturers should be evaluated to ensure high-quality and reliable results.

Maintenance and care also play a crucial role in preserving the effectiveness of surface treatments and coatings. Regular cleaning and proper handling are necessary to prevent damage and ensure longevity. Manufacturers and suppliers can provide guidelines for maintaining and cleaning treated or coated aluminum strips, as well as recommendations for repair and refurbishment options in case of damage or wear.

Summary

In conclusion, the surface treatment steps involved in enhancing aluminum strip properties are crucial for improving performance, protection, and aesthetics. The preparation phase ensures a clean and properly etched surface, allowing for better adhesion and treatment penetration. The application of the treatment or coating, whether it’s anodizing, painting, powder coating, cladding, or laminating, is performed using various methods to achieve even coverage and desired thickness. The curing or drying process helps the treatment or coating fully develop its properties, such as increased corrosion resistance, durability, and aesthetic appeal.

It is important to consider factors such as application requirements, environmental conditions, and budget constraints when selecting the appropriate treatment or coating. Proper maintenance and care, including regular cleaning and handling, are essential for preserving the effectiveness of the surface treatments and coatings.

By following these surface treatment steps and considering the specific needs of the aluminum strips, manufacturers and users can significantly enhance their performance, protection, and visual appeal. The combination of surface treatments and coatings allows aluminum strips to excel in various industries and applications, providing durable, corrosion-resistant, and aesthetically pleasing solutions.