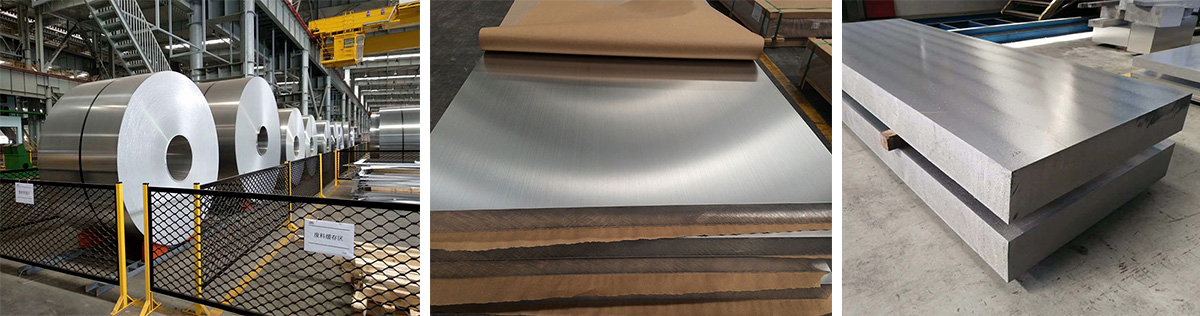

Aluminum Plate

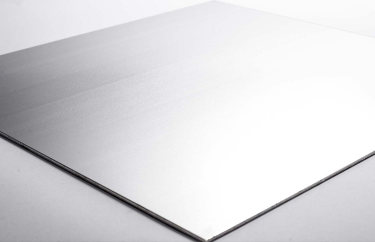

Aluminum Plate is highly resistant to corrosion, very ductile, and has a reflective finish. It is roughly 1/3 the weight of mild steel, so it is ideal for general sheet metal work where moderate strength is required but weight is an issue. Aluminum plate is straightforward to form or bend using hand tools or a bending brake. It also can be cut using a jigsaw with the correct blade, on a guillotine. Aluminium plates can be used for a wide range of applications from tooling plates, structural, general engineering, transport, agricultural, architectural, truck bodies, trailer parts ship, and boat building.

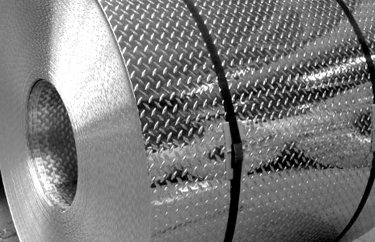

CHAL aluminium provides aluminum alloy products of Series 1000, Series 2000, Series 3000, Series 5000, Series 6000, Series 7000, and Series 8000 in different sizes. Main products include aluminum sheet, aluminum plate, aluminum foil, aluminum strip, aluminum coil, aluminum clad foil, aluminum checkered plate, CTP plate stock, PS plate stock, aluminum electrode capacitor foil, foil stock, deep-draw stock, brazing sheet, aluminum tread plate, etc.

Specifications of Aluminum Plate

| Size in mm | Theoretical mass (kg/plate) |

| 2000 × 1000 × 0.5 | 2.71 |

| 2500 × 1250 × 0.5 | 4.23 |

| 2000 × 1000 × 0.7 | 3.79 |

| 2500 × 1250 × 0.7 | 5.93 |

| 2000 × 1000 × 0.9 | 4.88 |

| 2500 × 1250 × 0.9 | 7.62 |

| 2000 × 1000 × 1.2 | 6.50 |

| 2500 × 1250 × 1.2 | 10.16 |

| 3000 × 1500 × 1.2 | 14.63 |

| 2000 × 1000 × 1.6 | 8.67 |

| 2500 × 1250 × 1.6 | 13.55 |

| 3000 × 1500 × 1.6 | 19.51 |

| 2000 × 1000 × 2.0 | 10.84 |

| 2500 × 1250 × 2.0 | 16.94 |

| 3000 × 1500 × 2.0 | 24.39 |

| 2500 × 1250 × 2.5 | 21.17 |

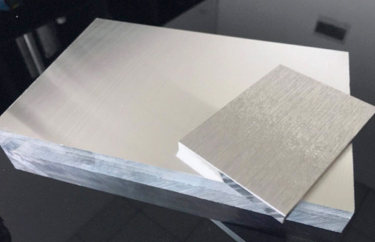

Common widths of aluminum plates are 1000mm, 1250mm, and 1500mm. Common lengths are 2000mm, 2500mm, and 3000mm. The aluminum plate can be cut as per the client’s requirements. Our aluminum plate has a wide range of thicknesses 3mm up to 100mm. Thinner than 3mm is considered to be an aluminum sheet. With an outstanding strength-to-weight ratio and natural corrosion resistance, aluminum plate/sheet is popular for a broad range of applications. Aluminum sheets and plates are used in everything from aerospace and aircraft manufacturing to beverage packaging, cryogenic storage, siding, gutters, and roofing for homes.

Aluminum & Aluminum Alloy Grade

Alloy Grade

1xxx, 2xxx, 3xxx, 4xxx, 5xxx, 6xxx, 7xxx, 8xxx

Tempers

F, 0, Hxxx, Txxxx

| Alloy Series | Alloy | Temper | Thickness(mm) | Width(mm) | Major alloying element |

| 1*** Series | 1050 1060 1100 | F, HO, H12, H14, H16,H18, H22, H24, H26, H32,H111, H112, T4, T6, T351, T651 | 1.0-500mm | ≤3000(max) | Pure aluminum (99.0% and greater) |

| 2*** Series | 2A12 2024 2017 | Copper is major addition | |||

| 3*** Series | 3003 3105 | Manganese is major addition | |||

| 4*** Series | 4045 4047 4343 | Silicon is major addition | |||

| 5*** Series | 5052 5A02 5A03 5A055754 5083 5086 | Magnesium is major addition | |||

| 6*** Series | 6061 6063 6082 | Magnesium and silicon are major additions | |||

| 7*** Series | 7075 7A04 7050 7175 | Zinc is the major addition | |||

| 8*** Series | 8006 8011 8079 | Other Alloys | |||

| This is for reference only, product details to the actual subject. | |||||

Typical Products of Aluminum Plate

- 1100/1060 Aluminum Plate

- 2024 Aluminum Alloy Plate

- 3003/3004 Aluminum Alloy Plate

- 6061/6082 Aluminum Alloy Plate

- 5052 Aluminum Alloy Plate

- 5083 Aluminum Alloy Plate

- Aluminum Cast Plate For Mold&Tooling

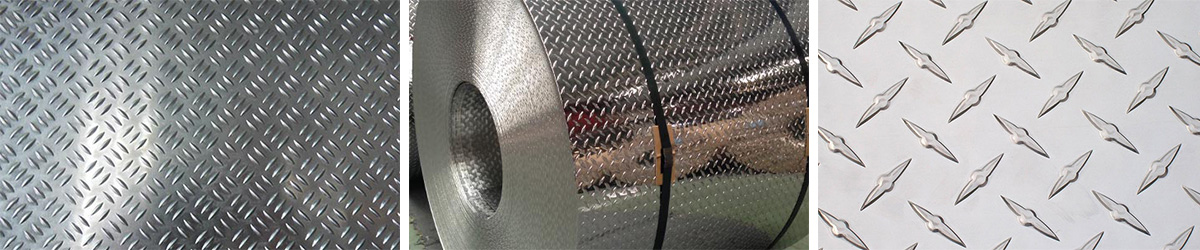

- Aluminum Tread Sheet/Plate (Aluminum Checker Plate)

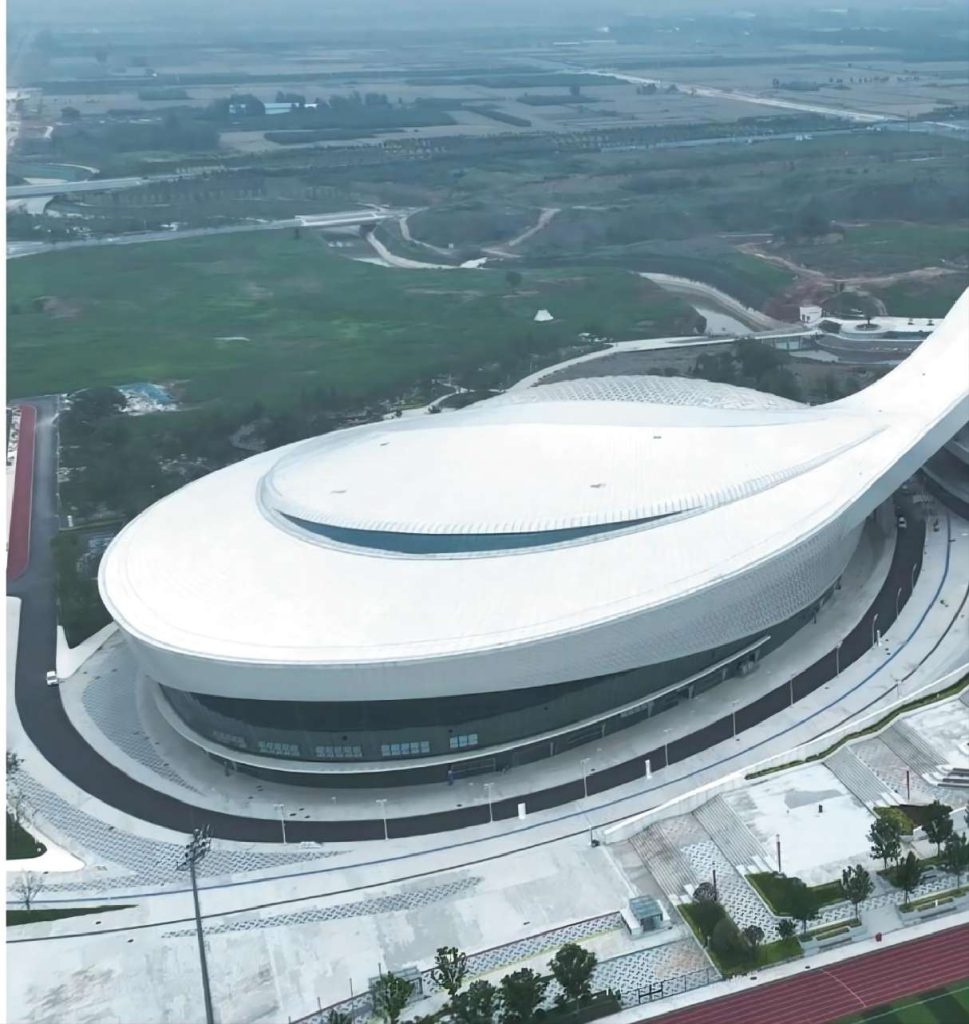

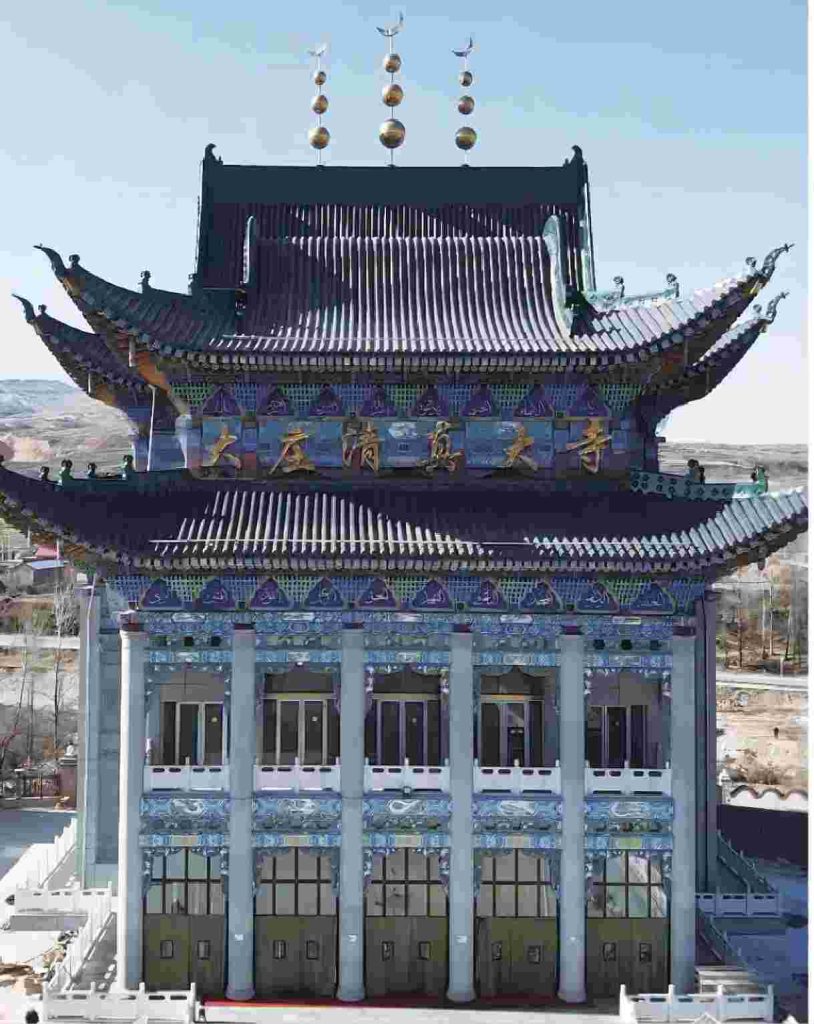

Applications of Aluminum Plate

Due to its good performance in physical properties, the aluminium plate is widely used in different industries, some of which include:

| Industry | Alloy |

| Aerospace | 7075 T651 2324 T3/T351J 7150 T7751 2024 T3 7085 T7651 2524 T351 7050 T7451 2017A T4/T451J 7055 T7751 Alcad 2024 T3 |

| Ship Building | 6082 T6/T651/Tl12 5754 H112 5052 H32/0 5083 H321/H116/H112/0 5086 0/H116 |

| Automotive | 6016 T4/T4P 5182 0 5754 0 6014 T4/T4P 6111 T4/T4P 7075 T4 6451 T4/T4 |

| Foil Stock (Coil) | 1235 H14/H16 8011 H14/H16 8079 H14/H16 8021 H14/H16 |

| Transportation, Construction, Hardware, Bottle Cap, Containers | 1060 H14/H16/H24/H26/0 6063 T4/T6/T651 3003 0/H1x/H2x 6061 T4/T6/T651 5052 H2x/H3x/0/H111/H112 6082 T4/T6/T651 5083 H3x/H112/H111/0 8011 H14/H16 5086 H3x/H112/H111/0 5182 0/H111/H112/H34 5454 0/H111/H112/H32 |

| Laptop, Ipad, Mobile Phone, 3C Material, Anodizing | 5252G H32/H34/H36 6061G T4/T6/T651 6063G T4/T6 5052 H32/H34/H36 5182 H34 |

| Can Body, Can End, Tap-Strip | 3004 H19 5182 H19 3104 H19 5052 5182 H48/H19 |

| Mold and Machinery | 2024 T351 6061 T651 5052 0/H111/H112 6063 T651 5083 0/H111/H112 7075 T651 6082 T651 |

Advantages of Aluminum Plate

- Lightweight-approximately one-third the density of steel.

- High Strength-some alloys can be substantially strengthened by work or by heat treatment.

- Corrosion Resistance varies depending on the alloy and the best resist marine exposure.

- Non-toxic-often used in contact with food.

- Workability-easily formed, machined, and welded.

- Reflectivity-bright finish options.

- Non-magnetic and non-sparking.

- High electrical conductivity.

- High thermal conductivity.

Quality Requirements of Aluminum Plate Cut to Size

- The surface should be clean and free of cracks and oxidized debris.

- The surface of the aluminum plate is allowed to have defects such as indentation, scratches, and roller indentation, but the depth cannot exceed the allowable negative deviation of the aluminum plate, and the minimum thickness should be guaranteed.

- The falling part with cladding bubbles is allowed.

- It is allowed to remove defects within the range of thickness differences.

- Custom to meet all your reasonable requirements.

Factors Affecting The Price of Aluminum Plate

There are many factors affecting the price of aluminum plates, mainly 3 factors:

- The price of aluminum ingots. The price of aluminum ingots is a direct factor affecting the price of aluminium plates. The price of non-ferrous aluminum ingots in the Yangtze River is changing every day and is unpredictable. This directly affects the price of aluminum plates.

- Alloy. The price of aluminum plate of each alloy series is different, for example, the price of 1 series and 6 series alloys will be much different.

- Specifications. The aluminum plate price of ordinary thickness specifications is not high, but the ultra-wide specifications are not necessarily. The wider the aluminum plate, the higher the price, so if there are no special requirements, it is recommended to choose the regular width.

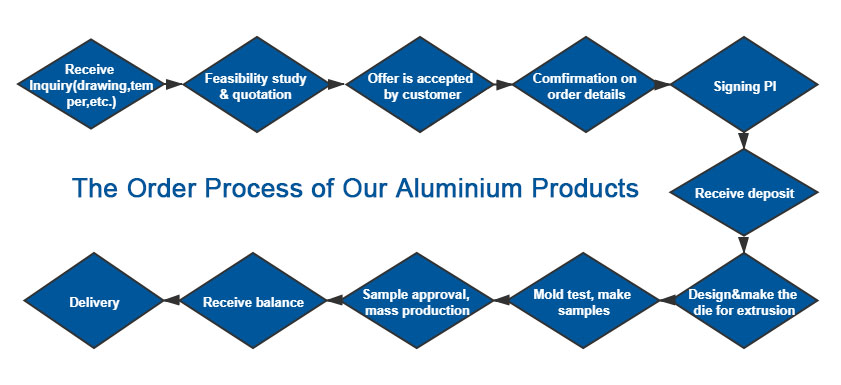

Order Process of Aluminum Plate

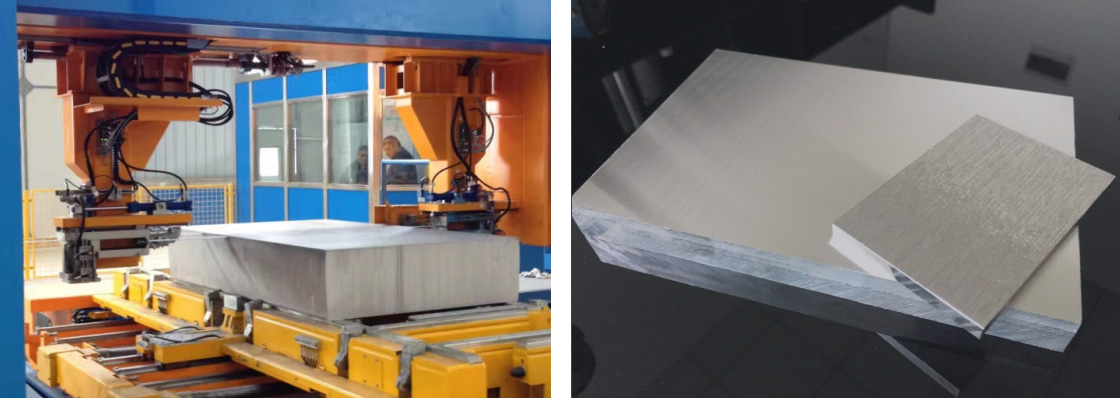

Key Points in Quality Control – Aluminum Casting

For making high-quality aluminum plates and sheets, aluminium slab quality is very important. It determines the final product quality. Using advanced equipment and optimized process to improve the quality of aluminum alloy slab is the foundation of high-performance aluminum alloy products.

CHAL has a wide range of cooperation with many world-class companies on material design, melt processing, casting process optimization, etc. It comprehensively helps us to improve the quality of the aluminum alloy slab and ensures our ability to provide high-performance aluminum alloy slab products for different industry customers.

All the melting and holding furnaces are supplied by the GAUTSCHI company. At the same time, CHAL introduces full sets of AL-EMS, refining units and casting machines. In casting house, combustion media is natural gas. All production lines are equipped with AL-EMS, in-furnace refining and online refining devices, etc. The computer-controlled melting system can realize automatic combustion control to ensure the temperature uniformity of aluminum melt and furnace chamber air and the stability of furnace pressure. The operation safety of furnace is also improved accordingly. To ensure the aluminum melt flow smoothly into the mold with uniform temperature, We choose the tilting type holding furnace, which is good for producing high-quality slab. As for the casting, CHAL aluminium corporation uses the hydraulic semi-continuous casting machine to ensure the controllability and stability of casting process.

The Difference Between Aluminum Plate and Aluminum Sheet

Basically, Aluminum plate and aluminum sheet are almost the same, the only difference is thickness. Aluminum plate is thicker than an aluminum sheet, both plate and sheet come in many forms including diamond, checkered, expanded, perforated and painted.

Equipment For Hot Rolling and Cold Roling

Hot Rolling

CHAL purchased 1 +1 +3 hot rolling mills from Germany, which can satisfy the production requirements of aerospace plates, and can produce the highest level plates for, shipbuilding, high-speed train and large-size container. Besides, we brought 1 +5 hot rolling mills. All the hot finish rolling mills adopt the eve flatness control technology, which makes the mills have the best flatness control ability in the world and can supply the best shape hot-rolled strip.

To manufacture high quality, over-dimension heavy and medium aluminum alloy plates applied in aerospace, shipbuilding and engineering industries, first-class equipment and process are inevitably necessary. CHAL introduces modern and advanced hot rolling mills, stretching machines, high precision quenching furnaces, aging furnaces and water immersion type detection devices from abroad, which are a strong guarantee of high-quality manufacturing products.

Cold Rolling

We purchased 3 sets of cold rolling mill machines (2 sets of the single-strand mill and 1 set of the three-stand tandem mill) from Germany. In addition, we introduce world-leading technologies and equipment, wholly imported vertical intelligent storage and logistic management system, and finishing lines that fulfill all the requirements for manufacturing various kinds of aluminium plate, sheet and strip products. The finishing lines include trimming line, tension leveling line, air-floating type quenching line, coating line and packaging line.

About Company

CHAL Aluminium Corporation is a fully integrated aluminum company that supplies all kinds of aluminum products and technical solutions. We are committed to being the leading supplier of aluminum plates, aluminum sheets, aluminum strips, aluminum foil, aluminum circles, aluminum heat transfer material, aluminum profiles, precision aluminum tubes, aluminum machining parts and stamping parts. CHAL aluminium corporation is one of the biggest aluminum manufacturers in China. We have a large scale plant, first-rate facilities, sufficient production capacity, most entire range of products. We have 6 manufacturing bases in five provinces. Headquarters base is located in Chongqing Xipeng aluminum industry town. We have 5 R&D Centers, more than 4000 employees, including 600 R&D staff, more than 200 patents, annual R&D investment exceeds 220,000,000RMB. The production capacity is about 320,000 tons.

To ensure quality, CHAL makes big investments in purchasing advanced equipment from abroad, including melting-holding furnaces, casting machines, pusher-type heating furnaces, 1+1+3 hot rolling mills, 1+5 hot rolling mills, stretching machines, roller hearth quenching furnaces and aging furnace, 3-stand tandem cold rolling mill, 2-stand tandem cold rolling mill and single stand cold rolling mill, intelligent high bay storage, tension leveling line, trimming line, air-floating type quenching line, packaging line and other finishing equipment.

Our high-end aluminium plate, sheet, strip and foil are mainly applied in aerospace, shipbuilding, engineering, HAVC/AC, construction, packaging, transportation, tooling, mold and electrical industries.

Sales Network

International: Europe, North America, South America, Asia-Pacific, Middle East, Africa, etc.

Domestic: South China (Guangdong Province, Guangxi Province, Fujian Province, Hainan Province), East China (Shanghai, Jiangsu Province, Zhejiang Province, Jiangxi Province), Central China (Henan Province, Hubei Province, Hunan Province, Shandong Province, Anhui Province), North China (Hebei Province, Shanxi Province, Tianjin, Beijing), West China (Qinghai Province, Gansu Province, Xinjiang Uygur Autonomous Region, Shaanxi Province, Tibet Autonomous Region, Sichuan Province, Yunnan Province, Guizhou Province), Northeast China (Liaoning Province, Jilin Province, Heilongjiang Province, Inner Mongolia Autonomous Region).

Certificates

CHAL Aluminium Corporation has passed quality system audit AS9100, IATF.16949, ISO.9001, ISO.14001:2004, OHSAS18001:2007 and got CE-Certificate EN 15088 of structural products for construction works; also certified by quality assurance system for PED 97/23/EC, AD 2000-Merkblatt WO, Nadcap, DNV, NK, ASB and CCS.