Reasons and Methods of Aluminium Foil for Sealing

Aluminium foil has been a staple in various industries for its versatility and effectiveness in sealing products. This thin, flexible metal sheet is renowned for its ability to provide an…

How to Choose the Right Aluminum Foil Duct for Your Needs?

Selecting the appropriate aluminum foil duct is crucial for ensuring optimal performance and safety in various applications, particularly in HVAC systems and kitchen ventilation. The right choice can enhance airflow efficiency,…

Heavy-Duty vs Industrial Aluminum Foil: Differences and Similarities

Aluminum foil, a versatile and essential material, finds extensive use in various industries due to its unique properties. However, not all aluminum foil is created equal. Two prominent types are…

Aluminium Foil Expiry Date: Maximizing Shelf Life and Use

Aluminum foil is a versatile kitchen essential used for everything from food storage and preparation to oven cooking and cleaning. While it seems like a simple product, understanding aluminium foil expiry…

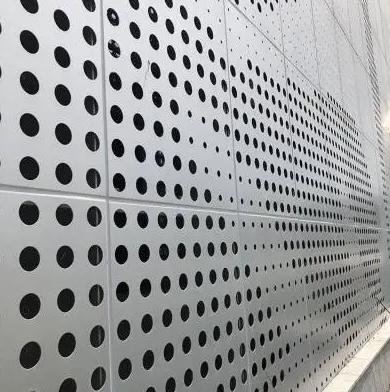

Top Applications for Aluminum Sheets with Holes in Architecture

Aluminum sheets with holes, also known as perforated aluminum sheets, have gained significant popularity in the field of architecture. These versatile materials offer a blend of functionality and aesthetic appeal,…

Aluminum Foil Tape: A Versatile Material in Aerospace

Aluminum foil tape is a versatile material widely used across various industrial and commercial sectors. Comprising soft aluminum foil coated with a transparent acrylic adhesive, this tape is known for its…

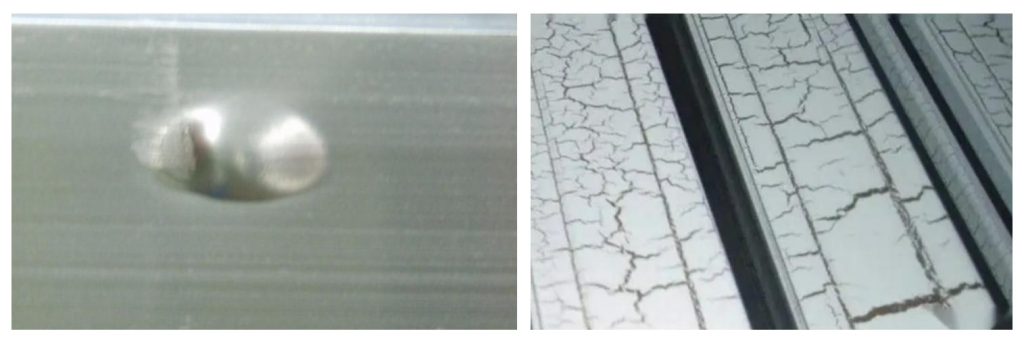

Common Aluminum Extrusion Defects: Causes and Solutions

Aluminum extrusion is a versatile process used to create a wide variety of shapes and components for countless applications. During this process, molten aluminum is forced through a die, shaping it into…

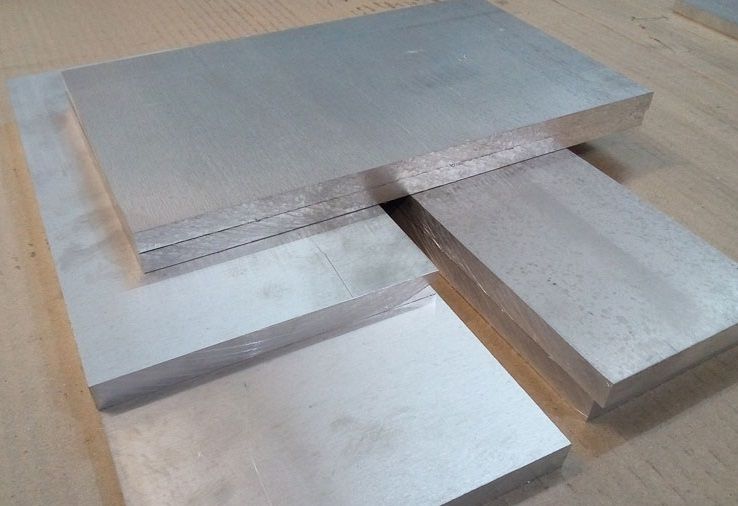

Why 6061 T651 Aluminum is Essential for Industrial Machinery?

Industrial machinery needs to be tough. It operates in demanding environments, frequently under pressure, and needs to perform consistently over long periods. 6061 T651 aluminum is a metal specifically chosen to meet these rigorous standards…

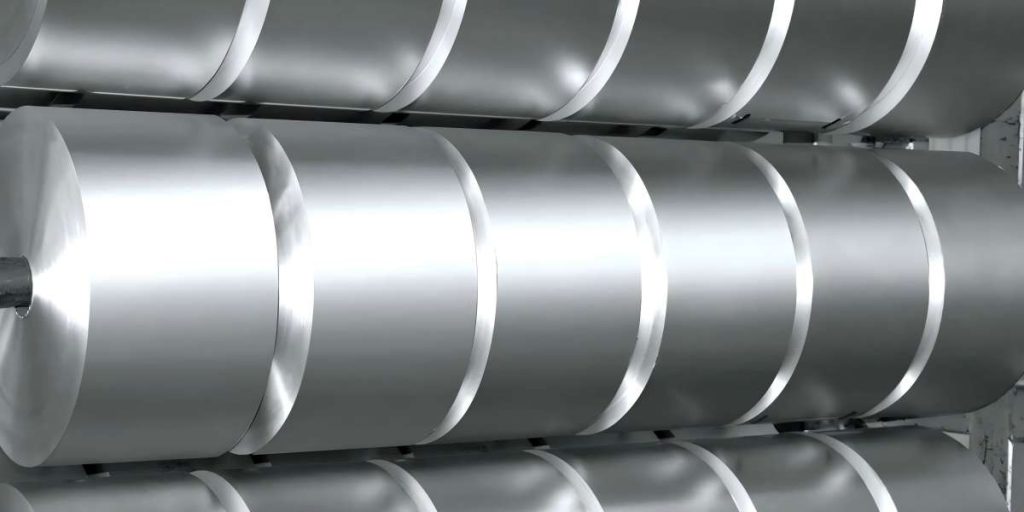

Pharmaceutical Aluminum Foil: A Critical Component in Drug Packaging

Pharmaceutical aluminum foil is a specialized material designed for packaging medical and pharmaceutical products. Its primary function is to act as a barrier, preventing moisture, oxygen, and other gases from entering…

Optimizing Aluminum Plate Design: A Comprehensive Guide

Aluminum plates are a versatile and popular material choice for various applications due to their unique combination of lightweight properties, strength, and formability. However, achieving optimal performance and aesthetics in…

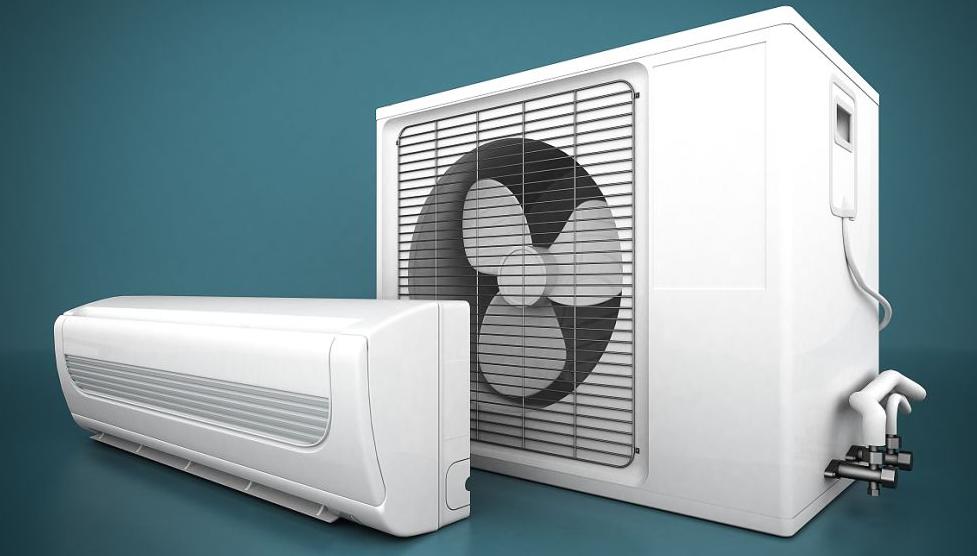

What are the Types of Aluminum Pipes for Air Conditioning?

Air conditioning systems are essential for maintaining comfortable indoor environments, especially in regions with extreme temperatures. One of the critical components of these systems is the piping, which transports conditioned…

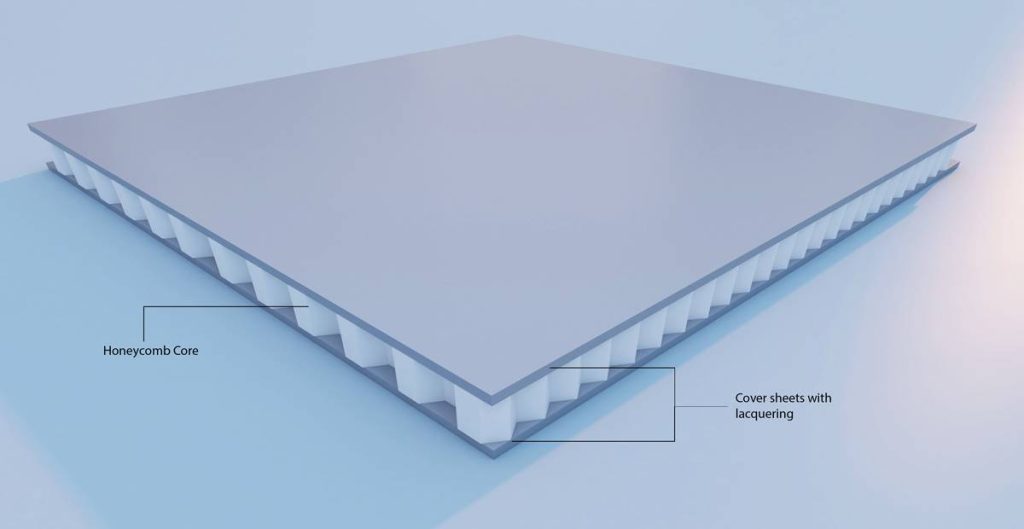

Aluminum Honeycomb Panels: A Versatile Material for Modern Construction

Aluminum honeycomb panels have become a popular choice in modern construction due to their unique combination of properties. They are lightweight yet remarkably strong, offering excellent sound and thermal insulation. This…