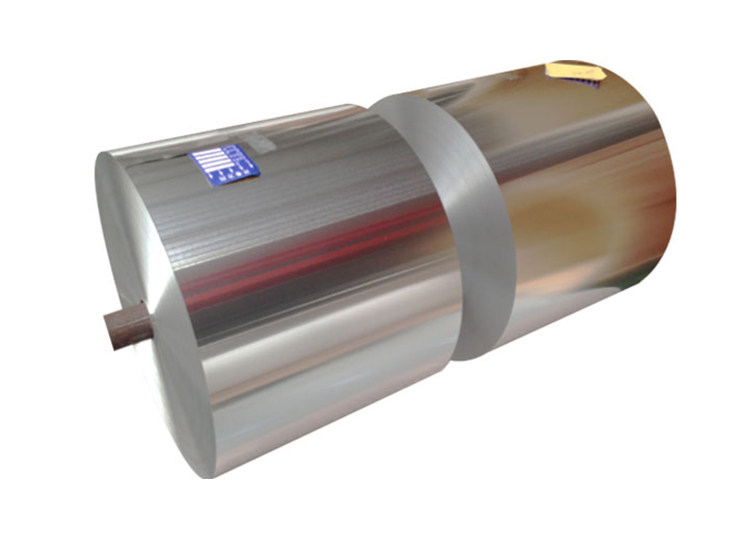

1235 Aluminum Foil

- 1235 aluminum foil the aluminum foil of aluminum content not less than 99.35%, CHAL Aluminium can process 0.014-0.2mm thickness of 1235 aluminum foil, because this product has excellent rust resistance, formability, and dissolving ability, then 1235 aluminum foil is widely used in cigarette packaging, cable, capacitor, tape, battery foil, flexible packaging, etc.

- Rolled in alloy 1235 with 99.35% minimum aluminum content, CHAL’s foil slit edges are very clean, resulting in a consistent unwind with minimal breaks.

1235 Aluminum Foil Technical Parameter

| Ingredient | Si+Fe | Cu | Mn | V | Zn | Ti | Cr | Other | Al |

| Content | ≤0.65 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.1 | ≤0.06 | – | 0.03 | 99.35 |

| Alloy type | 1235 Aluminium foil | ||||||||

| Alloy state | O, H18 | ||||||||

| Thickness (mm) | 0.014-0.2 | ||||||||

| Width (mm) | 10-1600 | ||||||||

| Length | Jumbo roll | ||||||||

Application of 1235 Aluminum Foil

1. Food Preparation: Aluminum foil is “dual-ovenable” and can be used in both convection and fan-assisted ovens. A popular use of foil is to cover thinner sections of poultry and meat to prevent overcooking. We also provide recommendations on limited uses of aluminum foil in microwave ovens.

2. Insulation: Aluminum foil is 88 percent reflective and is widely used for thermal insulation, heat exchanges, and cable liners. Foil-backed building insulation not only reflects heat but also provides a protective vapor barrier.

3. Electronics: Foil in electrical capacitors provides compact storage for electric charges. If the foil surface is treated, the oxide coating works as an insulator. Aluminum foil capacitors are commonly found in electrical equipment, including television sets and computers.

4. Geochemical Sampling: Aluminum foil is used by geochemists to protect rock samples. Foil provides a seal from organic solvents and does not taint the samples as they are transported from the field to the lab.

5. Art and Decoration: Anodizing aluminum foil creates an oxide layer on the aluminum surface that can accept colored dyes or metallic salts. Through this technique, aluminum is used to create inexpensive, brightly colored foils.

Properties of 1235 Aluminum Foil

1. High plasticity and corrosion resistance.

2. Electrical conductivity and thermal conductivity.

3. Gas welding, hydrogen welding, and resistance welding.

4. Under various pressure processing and extension, bending.

The Quality of CHAL’s 1235 Aluminum Foil

1. The surface of the aluminum foil should be clean, and smooth. There is no corrosion, empty, folding, brown staining, slotted, add edge, wrinkling, concave, and convex.

2. The surface of the aluminum foil is not allowed to have a serious color difference.

3. The end surface of the aluminum foil should be clean and tidy, there is no burr, wrong layer, bruising, or collapse.

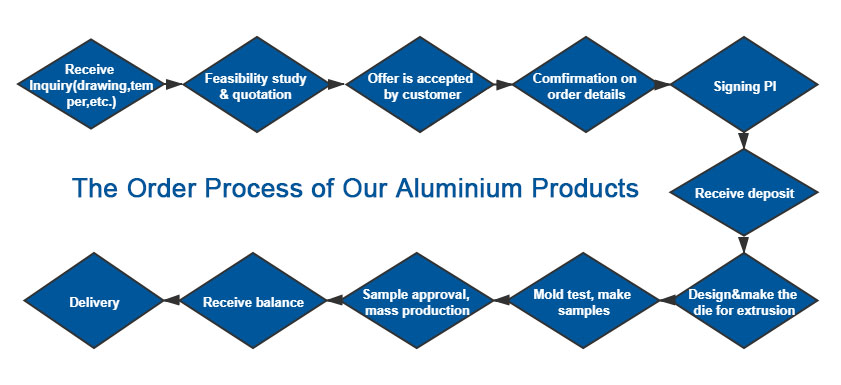

The Order Process of 1235 Aluminum Foil