Seamless aluminum tubes are a versatile material that is used in a wide variety of applications, including the chemical, oil, and gas industries. In these industries, seamless aluminum tubes are often the preferred material because of their unique properties. This article will discuss the properties of seamless aluminum tubes and their applications in the chemical, oil, and gas industries.

Properties of Seamless Aluminum Tubes

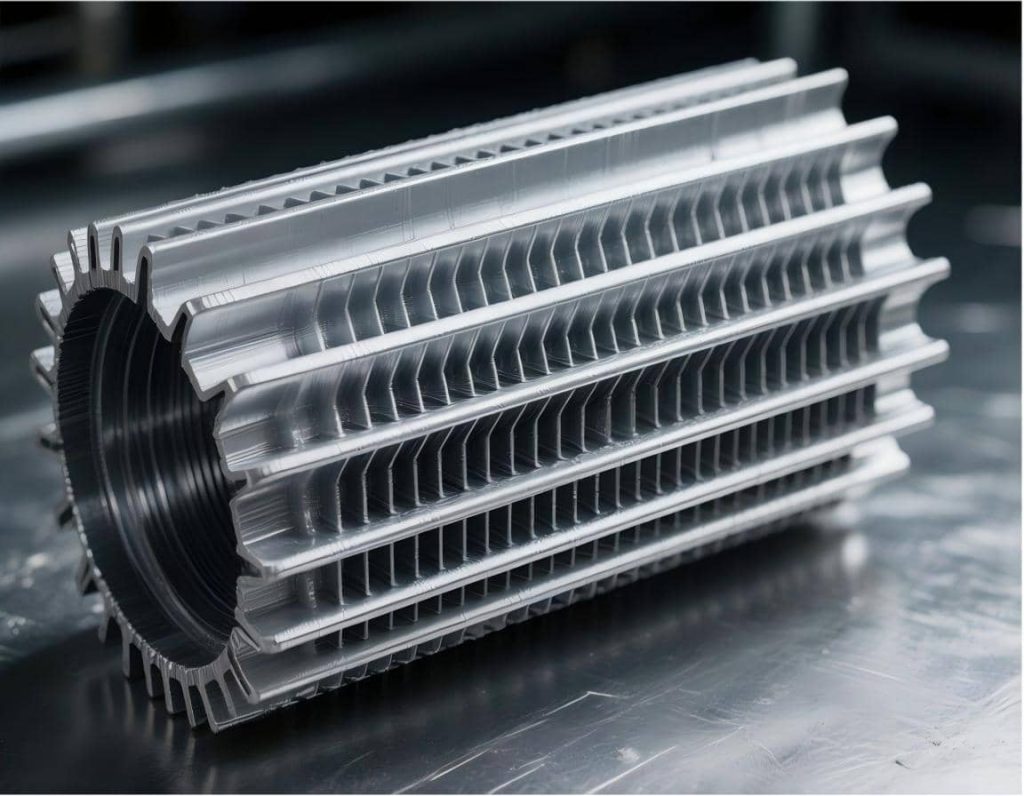

Seamless aluminum tubes are made from a solid piece of aluminum that is extruded or rolled into a tube. This process creates a tube with no seams or welds, which makes it stronger and more resistant to corrosion than welded aluminum tubes.

Lightweight

One of the most important properties of seamless aluminum tubes is their light weight. This makes them easy to transport and handle, which is essential for applications in the chemical, oil, and gas industries. For example, seamless aluminum tubes are often used in piping systems in these industries because they are lighter than steel pipes, which can save on transportation and installation costs.

Corrosion-resistant

Seamless aluminum tubes are also very resistant to corrosion. This is because aluminum forms a natural protective oxide layer on its surface when exposed to air. This oxide layer prevents the aluminum from corroding in most environments, including those that are exposed to harsh chemicals, salt water, and extreme temperatures.

Strong

Seamless aluminum tubes are also very strong. This is because the extrusion or rolling process that is used to create them work-hardens the aluminum, which makes it stronger and more resistant to deformation. This makes seamless aluminum tubes a good choice for applications where strength is important, such as in piping systems and pressure vessels.

Ductile

Seamless aluminum tubes are also ductile, which means that they can be bent and shaped without breaking. This makes them a good choice for applications where flexibility is important, such as in piping systems that need to be able to follow curves and bends.

Affordability

Seamless aluminum tubes are also relatively affordable. This is because aluminum is a relatively abundant metal, and the process of extruding or rolling aluminum tubes is relatively inexpensive. This makes them a cost-effective choice for a variety of applications.

Applications in the Chemical Industry

Seamless aluminum tubes are an essential material in the chemical industry due to their lightweight, corrosion resistance, and strength. They are used in a wide variety of applications, including:

- Piping: Seamless aluminum tubes are widely used for piping in chemical plants and refineries. Their lightweight nature makes them easy to transport and install, and their corrosion resistance makes them ideal for use with harsh chemicals.

- Reactors: Seamless aluminum tubes are used in reactors for chemical reactions. Their strength and resistance to high temperatures make them suitable for containing and controlling chemical reactions.

- Heat exchangers: Seamless aluminum tubes are used in heat exchangers for transferring heat. Their high thermal conductivity makes them efficient at transferring heat between fluids, and their corrosion resistance makes them suitable for use with a variety of chemicals.

- Condensers: Seamless aluminum tubes are used in condensers for condensing vapors. Their large surface area and high heat transfer coefficient make them efficient at condensing vapors, and their corrosion resistance makes them suitable for use with a variety of chemicals.

Applications in the Oil and Gas Industry

Seamless aluminum tubes are also widely used in the oil and gas industry due to their lightweight, corrosion resistance, and strength. They are used in a variety of applications, including:

- Piping: Seamless aluminum tubes are used for piping in oil and gas pipelines. Their lightweight nature makes them easy to transport and install, and their corrosion resistance makes them ideal for use with harsh chemicals like crude oil and natural gas.

- Well casings: Seamless aluminum tubes are used for well casings in oil and gas drilling. Their strength and resistance to high pressures make them suitable for protecting the wellbore from collapse.

- Pumps: Seamless aluminum tubes are used in pumps for oil and gas production. Their lightweight nature makes them easy to transport and install, and their corrosion resistance makes them suitable for use with harsh chemicals like crude oil and natural gas.

- Valves: Seamless aluminum tubes are used in valves for oil and gas control. Their strength and resistance to high pressures make them suitable for controlling the flow of oil and gas.

Conclusion

Seamless aluminum tubes are a versatile and reliable material that is well-suited for use in the chemical, oil, and gas industries. Their unique properties, such as their lightweight, corrosion-resistance, strength, ductility, and affordability, make them a popular choice for these applications. As the demand for lightweight, corrosion-resistant, and strong materials continues to grow, seamless aluminum tubes are likely to continue to be a popular choice for a wide variety of applications.