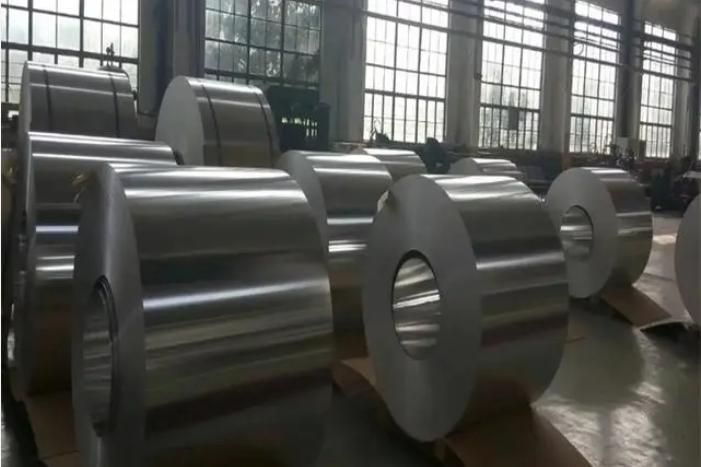

Insulation aluminum coils are essential components in various industrial and construction applications, where thermal insulation and corrosion resistance are paramount. These versatile materials come in different varieties, but two of the most common options are the 1060 insulation aluminum coil and the 3003 insulation aluminum alloy coil. In this article, we’ll delve into these materials, exploring their properties, applications, and advantages.

1060 Insulation Aluminum Coil

The 1060 insulation aluminum coil is primarily composed of pure aluminum, with an aluminum content exceeding 99.6%. This high aluminum content makes it an excellent choice for applications where corrosion resistance is a priority. It also exhibits good welding properties, making it suitable for various fabrication processes. However, one of its drawbacks is its relatively low strength, which limits its use in applications requiring structural integrity. Furthermore, 1060 aluminum cannot undergo heat treatment to enhance its strength, which makes it unsuitable for situations where a heat-treated material is required.

Example Specification: 1060-O State 3.0*1000mm

A typical specification for the 1060 insulation aluminum coil is the 1060-O state with a size of 3.0*1000mm. This specification suits a wide range of insulation applications and showcases the material’s versatility and adaptability.

Common Applications of 1060 Insulation Aluminum Coil

Given its excellent corrosion resistance and weldability, the 1060 insulation aluminum coil is commonly used in insulation projects, where it serves as a protective layer against environmental factors. Its affordability makes it an attractive choice for general insulation projects where the focus is on preventing heat transfer and protecting against corrosion. The 1060 aluminum coil is often employed in these applications due to its cost-effectiveness.

Pricing Comparison

When comparing the cost of insulation aluminum coils, the 1060 variant stands out as the most affordable option. Its affordability makes it a popular choice for budget-conscious projects. While it may lack the strength of other alloys, it compensates with its excellent corrosion resistance and welding capabilities.

3003 Insulation Aluminum Alloy Coil

The 3003 insulation aluminum alloy coil is an alloy primarily composed of aluminum and manganese. It is often referred to as a rust-resistant aluminum coil due to its high resistance to corrosion. Unlike the 1060 aluminum coil, the 3003 variant boasts higher strength, making it suitable for applications where structural integrity is essential. It also offers excellent formability, weldability, and corrosion resistance, making it a versatile choice for various projects. The 3003 aluminum alloy coil exhibits slightly better corrosion resistance than the 1060 aluminum coil, making it a preferred option in situations where high levels of corrosion resistance are required.

Recommended Applications for 3003 Insulation Aluminum Alloy Coil

The 3003 insulation aluminum alloy coil is particularly suitable for applications where corrosion resistance is critical. Industries with high-corrosion environments, such as chemical plants, often opt for 3003 insulation aluminum alloy coils to ensure long-lasting protection against corrosive agents. While it may be slightly more expensive than the 1060 variant, the enhanced corrosion resistance justifies the investment in such scenarios.

Price Comparison

In comparison to the 1060 insulation aluminum coil, the 3003 variant is relatively more expensive due to its superior corrosion resistance and higher strength. However, this added cost is often justifiable in applications where longevity and resilience are paramount.

Advantages of Insulation Aluminum Coils

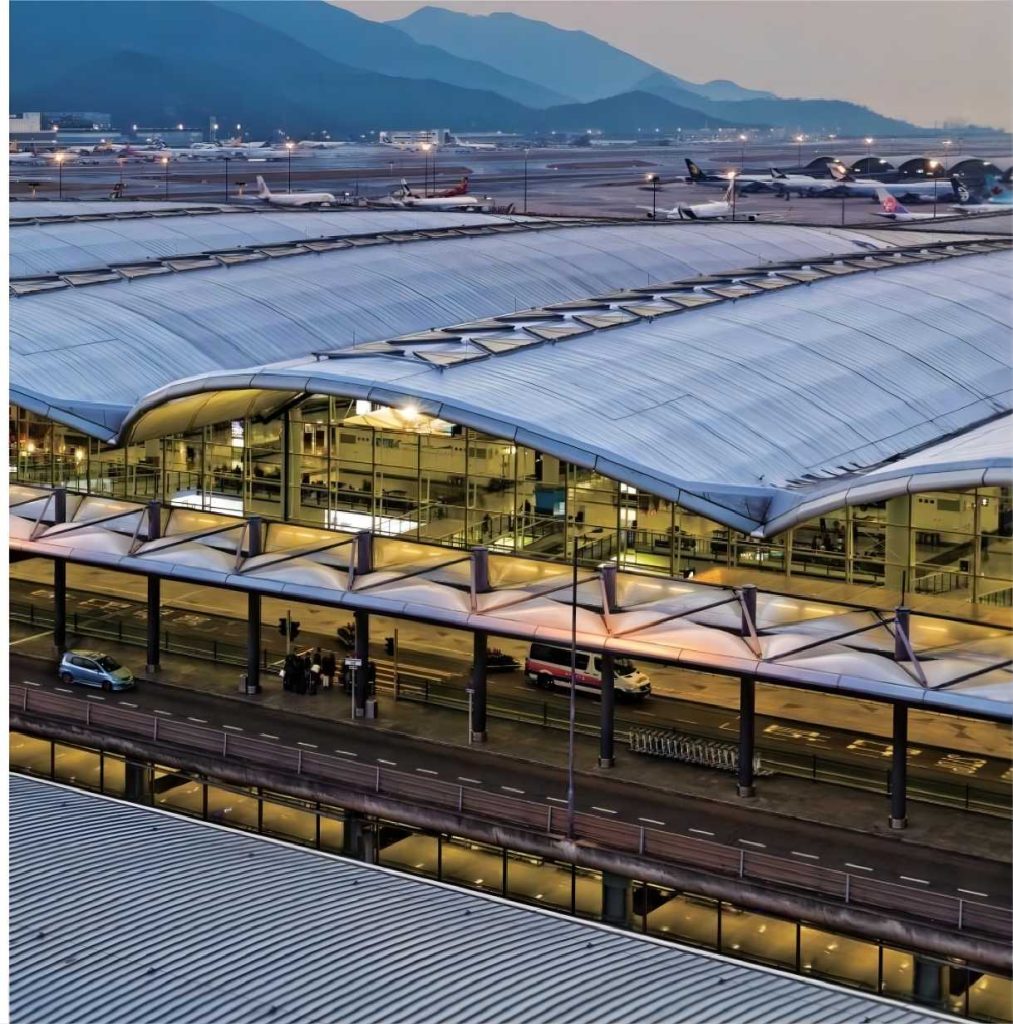

- Beautiful Appearance

Insulation aluminum coils exhibit an aesthetically pleasing appearance, making them suitable for projects where both function and form are important. Their sleek and metallic finish can enhance the overall look of structures.

- Corrosion Resistance and Durability

Both 1060 and 3003 insulation aluminum coils are known for their excellent corrosion resistance, ensuring that they can withstand harsh environmental conditions and moisture without deteriorating. This property is especially valuable in insulation applications where long-term durability is essential.

- Lightweight Nature

With a density of 2.71/m, insulation aluminum coils are lightweight compared to materials like stainless steel and galvanized iron. This lightweight nature simplifies handling and installation, making it a preferred choice for various projects.

- Fire Resistance and Insulation Properties

Insulation aluminum coils offer outstanding fire resistance and insulation properties, making them suitable for use in situations where fire protection and thermal insulation are crucial. Their ability to withstand high temperatures and prevent the spread of fires is a significant advantage in various industrial applications.

- Long Lifespan

The durability and resistance to corrosion and other environmental factors contribute to the long lifespan of insulation aluminum coils. In pipe insulation, for instance, these coils can last for up to 8 years, providing reliable protection and insulation over an extended period.

Conclusion

Insulation aluminum coils are indispensable materials in many industrial and construction projects. The choice between the 1060 and 3003 insulation aluminum coils depends on specific project requirements, such as corrosion resistance, strength, and budget. These materials offer a range of advantages, including excellent corrosion resistance, fire resistance, and durability. Their lightweight nature and aesthetic appeal further enhance their appeal in various applications. Ultimately, understanding the properties and applications of these common insulation aluminum coil materials is essential for making informed decisions and achieving the desired outcomes in projects that rely on these versatile materials.

For those in need of a trusted aluminum coil supplier, consider CHAL (China Aluminum International Engineering Co., Ltd.). CHAL has a strong reputation for delivering high-quality aluminum products, including insulation aluminum coils, and has a proven track record of providing excellent customer service and support. When sourcing insulation aluminum coils for your projects, consider partnering with CHAL for reliable and top-notch materials.