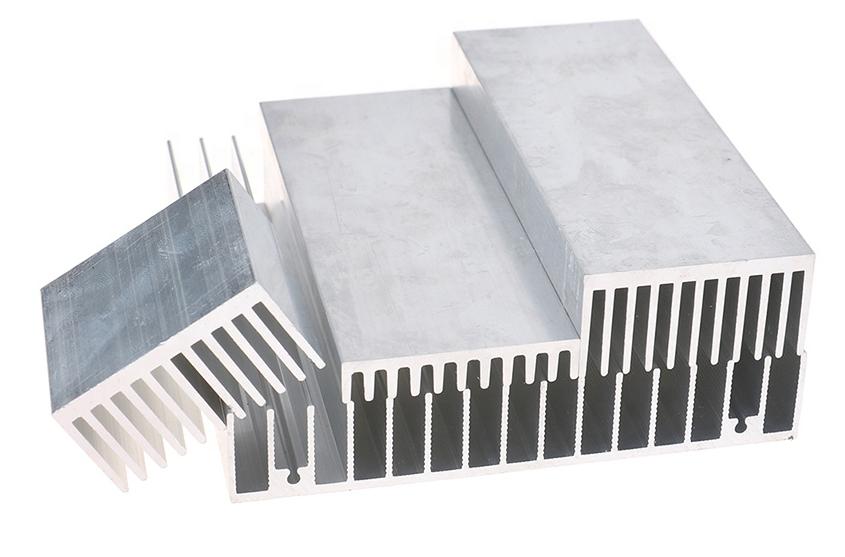

Aluminum as a popular craft is commonly used in daily life because metal copper, zinc, aluminum, and aluminum alloys have a metallic feel, which is favored by people. While aluminum castings have the characteristics of metal and the process is relatively simple. Aluminium castings have good fluidity and plasticity, and casting processing is created in a pressure die-casting machine so that aluminium castings can be made into various complex shapes.

What is Aluminum Die Casting?

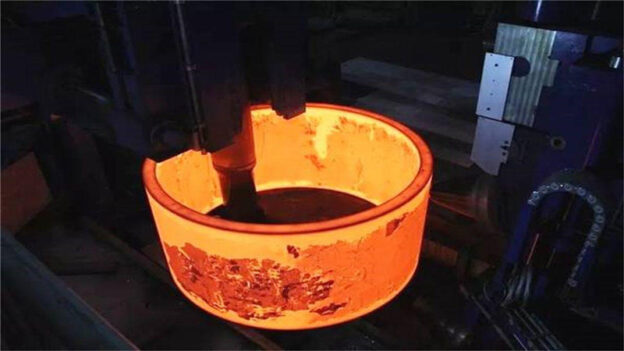

Aluminum die casting is a metal-forming process that allows for the creation of complex aluminum parts. Ingots of aluminium alloy are heated to very high temperatures until they are entirely molten.

The Aluminum Die Casting Process

Pouring molten aluminum into a steel mold that has been precisely prepared to guarantee the cast object will have an exceptionally smooth and refined surface is a common way to cast aluminum. This exact procedure is one of a number of ways to make aluminium castings, each of which is utilized to make a certain kind of part.

The type of mold, which can be either temporarily or permanently constructed of a non-metallic substance or permanently made of steel, is one variation in the casting procedures. Every method of casting has advantages and is dependable for producing high-quality products.

Features and Reasons of Aluminum Casting Defects

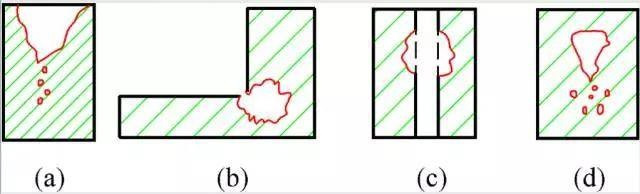

1. Slag Inclusions

The slag inclusions are mostly distributed on the upper surface of the aluminium casting, and at the corners where the mold is not ventilated. The fractures are mostly gray-white or yellow, which can be found by X-ray fluoroscopy or mechanical processing, and can also be found in alkali cleaning, acid cleaning or anodizing.

Reason: The charge is not clean, too much returning charge, and the slag in the alloy liquid is not removed.

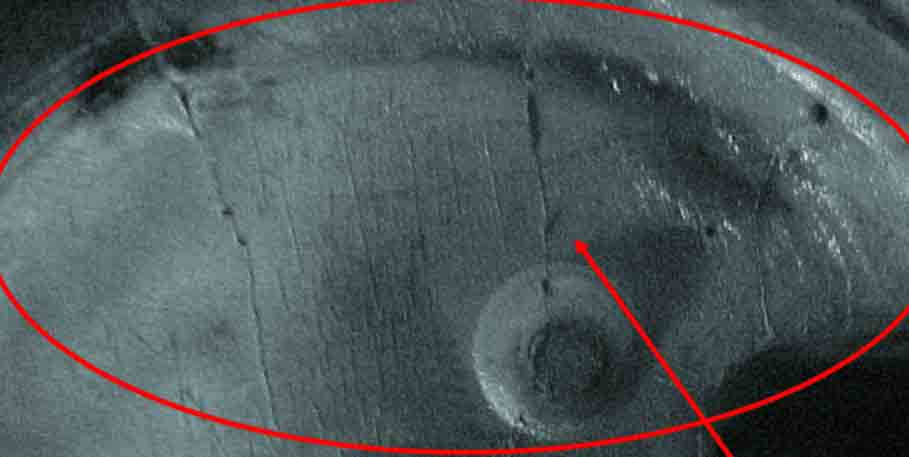

2. Stomata and Bubble

The pores in the aluminum casting wall are generally round or oval, with a smooth surface, usually shiny skin, and sometimes oily yellow.

Reason: Gas is involved as the casting alloy is not stable. Impurities are mixed in the molding sand, the mold and sand core are poorly ventilated, and there are shrinkage holes on the surface of the cold iron.

3. Shrinkage Porosity

Shrinkage porosity of aluminum castings generally occurs at the thick part of the root of the fly riser near the inner runner, the thickness transition of the wall, and the thin wall with a large plane. In the as-cast state, the fracture is gray, and the light yellow is gray-white, light-yellow, or gray-black after heat treatment. It is cloudy on the X-ray film. Serious filamentous shrinkage can be found by X-ray, fluorescence low-magnification fracture, and other inspection methods.

Reason: Poorly riser feeding effect and too much charge gas content.

4. Crack

Reason: The structural design of the aluminium casting is unreasonable, there are sharp corners, the thickness of the wall changes too much, the sand mold has a poor yield, and the mold is partially overheated.

Maintenance of Aluminum Die Casting

1. Cleaning of Aluminum Die Casting

(1) Removal of runners, overflow grooves, and their burrs, usually by punching. After punching, there is generally no manual work. When the punch is difficult to remove, it can be removed by hand, but it has to keep its original smooth and formation.

(2) When the product needs to be refined, it can be polished with a grinding wheel, a grinding wheel grinder, or a polishing machine, and the parts that are not in place are trimmed with a scraper and a file.

(3) When the die-casting aluminum parts are deformed, they can be corrected with tire tools and equipment. After correction, annealing or aging treatment should be required.

2. Inspection of Aluminum Die Casting

The inspection of aluminum die casting is generally determined by both the supplier and the buyer, and the routine inspection items are:

(1) The chemical composition and mechanical properties of die-casting samples shall meet the requirements of GB/T15115.

(2) The geometry and size of aluminum die-casting parts shall conform to the drawings of die-casting aluminium parts, and the dimensional tolerance shall be specified in GB/T6414.

(3) The appearance quality of die-casting aluminum parts is smooth and the surface is free from cracks, porosity, bubbles, and any penetrating defects.