What is 6063 Aluminum Alloy?

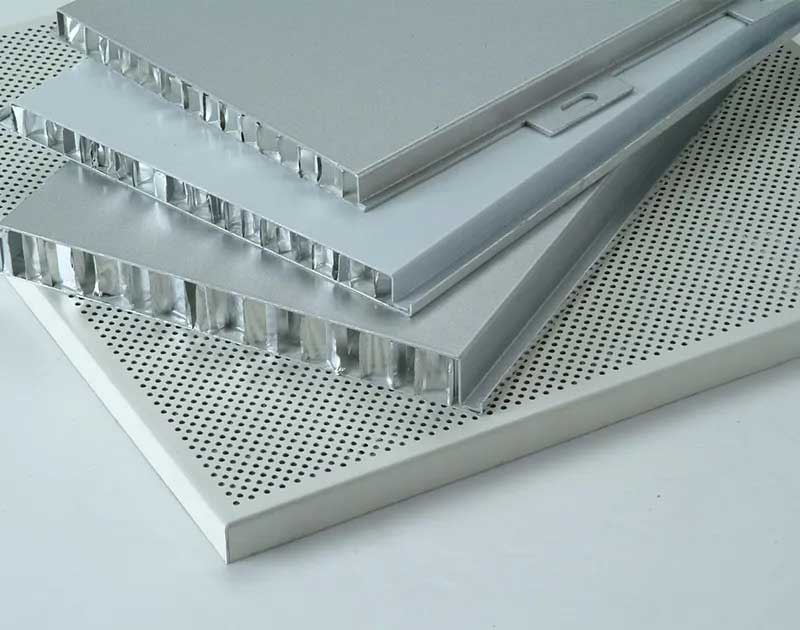

6063 aluminum alloy sheet is the most commonly used in aluminum extrusion, thus making it into account makes sense. The usage of this alloy in architectural applications is widespread. Therefore, it is frequently referred to as architectural aluminum.

It is a medium-strength alloy that is utilized in a variety of products, including railing, window and door frames, roofs, balustrading, sign frames, shop fittings, irrigation tubing, building supplies, electrical, marine, and piping, as well as recreation equipment, storage tanks, truck frames, and trailers.

Chemical Composition of 6063 Aluminum Alloy

The chemical composition of 6063 aluminum is the most crucial section of high-quality aluminium alloys. The main elements of the 6063 chemical composition are magnesium and silicon.

According to the range of 6063 chemical compositions specified in the national standard GB/T3190, different amounts of chemical composition will result in different properties. When the range of chemical composition is large, the performance variations will fluctuate in a wide range. As a result, the overall performance of the profile will be uncontrollable.

|

Material |

Chemical Element and Composition Element |

||||||||

|

Silicon(si) |

Iron(fe) |

Copper(cu) |

Manganese(Mn) |

Magnesium(Mg) |

Chromium(Cr) |

Zinc(Zn) |

Titanium(Ti) |

Aluminum(Al) |

|

|

6063 Aluminum |

0.2-0.6 |

≤0.35 |

≤0.1 |

≤0.1 |

0.45-0.9 |

≤0.1 |

≤0.1 |

≤0.1 |

Balance |

How to choose the content of chemical composition?

- Mg2Si

The heat treatment strengthening effect of 6063 aluminum alloy increases with Mg2Si content. When the amount of Mg2Si is in the range of 0.71% to 1.03%, the tensile strength increases approximately linearly with the increase of the amount of Mg2Si, but the increase in deformation resistance makes the process more difficult. However, when the amount of Mg2Si is less than 0.72%, for products with a small extrusion coefficient (≤ 30), the tensile strength value is in danger of not meeting standard requirements. When the amount of Mg2Si exceeds 0.9%, the plasticity of the alloy tends to decrease.

According to the GB/T5237.1-2000 standard, 6063 aluminum alloy T5 state profile should be σb≥160MPa, T6 state profile σb≥205MPa.

But it was proved that the alloy can reach up to 260MPa. However, mass production is affected by many factors, and it is impossible to ensure that all alloys can reach the highest number. Comprehensive consideration, the profile should not only have high strength to ensure the product meets the standard requirements but also make the alloy easy to extrude, which is conducive to improving production efficiency. When we design the alloy strength, we take 200MPa as the design value for the profiles delivered in the T5 state. When the tensile strength is about 200MPa, the amount of Mg2Si is about 0.8%. For profile in the T6 state, when we design the value of tensile strength as 230MPa, the amount of Mg2Si increased to 0.95% at this time.

- Mg

If the content of Mg2Si was confirmed, we can get the content of Mg by the way: Mg%=(1.73×Mg2Si%)/2.73

Mg is a flammable metal and will burn during smelting operations. When confirming the control range of Mg, the error caused by burning should be considered, but it should not be too wide to lose the alloy properties. We control the fluctuation range of Mg at 0.04%, T5 profiles take 0.47% to 0.50%, and T6 profiles take 0.57% to 0.60%.

- Si

The content of Si has to meet the requirement that all Mg can form Mg2Si. Due to the ratio of the relative atomic mass of Mg and Si in Mg2Si is Mg/Si=1.73, the basic amount of Si is Si(base)=Mg/1.73. However, the practice has proved that if the ingredients are based on Si, the tensile strength of the alloy is often low and unqualified. It was caused by an insufficient amount of Mg2Si in the alloy. The reason is that the impurity elements such as Fe and Mn in the alloy draw Si. For example, Fe can form an ALFeSi compound with Si. Therefore, there needs to have excess Si in the alloy to make up for the loss of Si.

Excess Si in the alloy also plays a supplement role in improving the tensile strength. The increase in tensile strength of the alloy is the sum of Mg2Si and excess Si. When the Fe content in the alloy is high, Si can also reduce the adverse effects of Fe. However, Si will reduce the plasticity and corrosion resistance of the alloy, the excess Si should be reasonably controlled. According to experience, our factory believes it is better to choose the excess Si content in the range of 0.09% ~ 0.13%.

Conclusion

The amount of Mg2Si in the 6063 aluminum alloy profile should be controlled within the range of 0.75% to 0.80%, which can fully meet the requirements of mechanical properties. In the case of normal extrusion coefficient (≥30), the tensile strength of the profile is in the range of 200~240 MPa. The content in this way not only has good plasticity, easy extrusion, high corrosion resistance, and excellent treatment performance but also saves alloying elements. However, it is necessary to pay special attention to the control of impurity Fe. If the Fe content is too high, the extrusion force will increase. The surface quality of the extruded material will have deteriorated, the anodic oxidation color difference will increase, the color will be dark and dull, and Fe will also reduce the plasticity and corrosion resistance of the alloy. The practice has proved that it is reasonable to control the Fe content within the range of 0.15% to 0.25%.