In recent years, with the wide application of new technologies and new processes, a new type of heating tube material-finned tube was born. A finned tube is a kind of heat exchange element. In order to improve the heat exchange efficiency, fins are usually added to the surface of the heat exchange tube to increase the external surface area (or internal surface area) of the heat exchange tube to achieve the purpose of improving the heat exchange efficiency. Such a heat exchange tube.

The finned tube is the core component of the air radiator, and a separate finned tube can also be used as a heat exchanger. There are many varieties of finned tube heat exchangers. In terms of materials, there are carbon steel, copper, aluminum, stainless steel, etc., as well as composite materials, such as steel-aluminum composite, that is, the base tube uses steel and the fins use aluminum; from the fin-type, there are ring fins, longitudinal fins, Spiral fins; fins can be either outside the tube or inside the tube, but there are more outer fins; the process can be integral rolling, welding with the tube, or casting.

Due to their different characteristics, various industries need to choose finned tubes of different types and materials. This article will introduce you to four small pieces of knowledge about radiator finned tubes, and take you to understand heat exchanger finned tube.

The working principle of heat exchanger finned tube

The heat exchanger uses a single metal finned tube as the heat exchange element, and it has to be resistant to high temperature and corrosion in the harsh environment of high temperature and humidity for a long time. Single metal finned tubes for heat exchangers must meet the following characteristics to be qualified:

1) Anti-corrosion performance

2) Wear resistance

3) Low thermal contact resistance

4) High stability

5) Anti-fouling ability

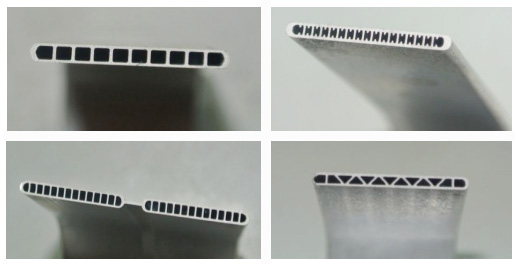

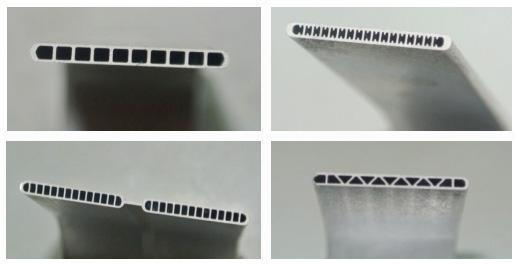

Conventional type of finned tube

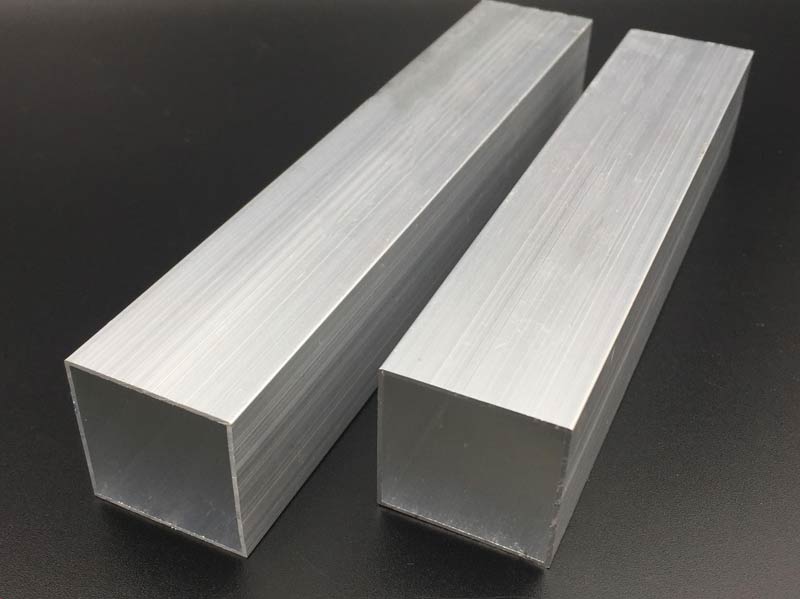

- Aluminum Rolled Finned Tube

The base tube (the base tube can be carbon steel, stainless steel, or copper) is sleeved in the form of an aluminum tube, which is extruded by a machine to form a fin. The base of the fin is closely attached to the outer wall of the tube, with a high heat transfer coefficient and excellent heat transfer performance.

- Spiral Wound Finned Tube

The finned tube is in the form of a base tube wound with a steel strip, which can be (carbon steel, stainless steel). This type of finned tube is suitable for various types, widely used in air radiators, economizers, stainless steel coiled tubes, and suitable for occasions with high quality requirements.

- High-frequency welding finned tube

This type of finned tube is mostly used for base tubes with a diameter of 10-219mm. The fins are welded on the surface of the base tube using the principle of high-frequency welding. This type of finned tube has a high heat transfer coefficient and a high fin thickness, which is stronger than other finned tubes, and the fins are relatively difficult to damage and have a long service life.

- Tandem finned tube/air-conditioning finned tube

The fins composed of air-conditioning fins with a base and a fixed pitch are generally made of copper tube wire and aluminum sheet. Nowadays, there are many straw stainless steel wire sheets to increase the characteristics of anti-acid and alkali corrosion environment;

Advantages of heat exchanger finned tube

1. The installation is simple and economical, reducing the connection points, making the installation more economical and faster, and reducing the probability of water leakage at the connection.

2. It is easy to maintain. After the fin tube is installed, maintenance is basically no longer needed.

3. High efficiency. The finned tube is full-contact welding of the fin and the steel tube. The heat dissipation area is more than 8 times that of the bare tube. The interior is smoother and the internal water flow resistance is small.

4. Long service life, high mechanical strength of the combination of fin and pipe, tensile strength of 196Mpa or more, hot-dip galvanizing can be used inside and outside the pipe.

These issues should be considered when choosing heat exchanger finned tubes: The distance and height of the finned tube radiator mainly affect the finning, and the finning ratio has a great relationship with the film heat transfer of the medium inside and outside the tube. If the heat transfer coefficients of the inner and outer films of the tube are quite different, a finned tube with a larger fin ratio, such as steam heating air, should be selected. When there is a phase change in one side of the medium, the difference in heat transfer coefficient will be larger, such as the exchange of hot and cold air. When the hot air drops below, a finned tube heat exchanger can be used. In the case of heat exchange between air and air without phase change, or heat exchange between water and water, a bare tube is usually more suitable. Of course, a low-finned tube can also be used, because at this time it is a weak heat supply coefficient, and strengthening either side of it will have a certain effect. However, the effect of too large finning ratio is not obvious, and the internal and external contact area of a good tube is strengthened at the same time, and a threaded tube or a fluted tube can be used.

Of course, if you are still confused about whether the heat exchanger fin tube can meet your needs, or you are looking for a reliable heat exchanger fin tube manufacturer, you can contact us. We are Chal, a professional comprehensive aluminum company in Chongqing, China. We provide a full range of heat exchanger finned tubes. The finned tubes are of reliable quality, high performance, complete design, and competitive prices. We can provide you with heat exchanger fin products suitable for you in the shortest time.