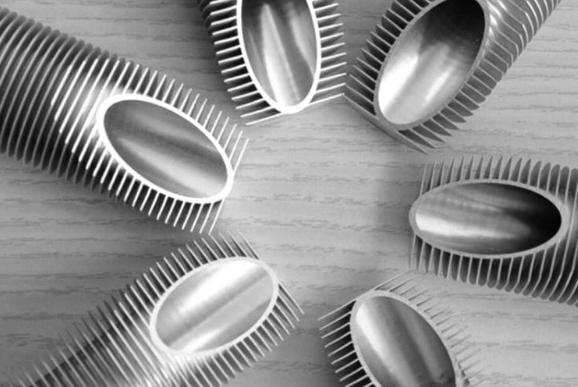

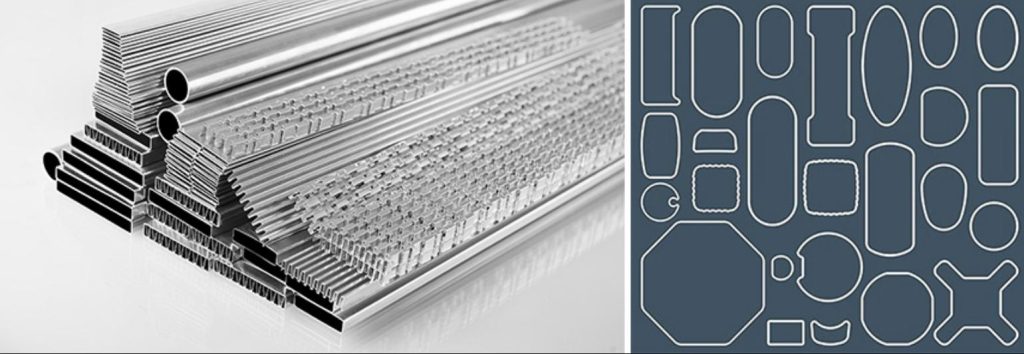

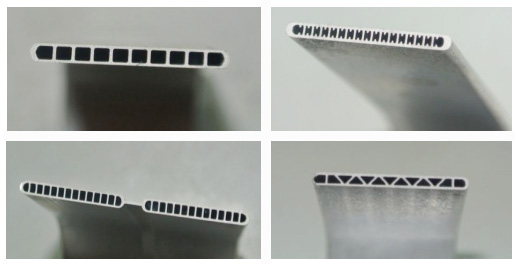

Parallel flow aluminum flat tube (“also known as aluminum alloy porous micro-channel tube) is a thin-walled porous binding tubular material. Parallel flow aluminum flat tube is an air conditioning system new environmentally friendly refrigerant carrying pipe component (material). Due to high technical content, it is extremely difficult to manufacture. The aluminium tube manufacturer requires extremely high production technology to produce qualified micro-channel aluminum tubes.

The production technology of parallel aluminum flat tube has the following aspects:

1. Ultra-large Extrusion Ratio

The extrusion ratio is a ratio between the broken area before the material heat extrusion before the material is extruded. In general, it is 8 ~ 50 times, such as 0.5m before the extrusion, turns 25m after extrusion, and the extrusion ratio is 50 times. If the extrusion is greater than 50 times, in general, the porous extrusion is generally extruded, so that the heat squeezed profile is generally strip-saving. However, the extrusion ratio of the parallel flow aluminum is more than 400 times, which is more than 8 times more than the aluminum extrusion limit process.

Since there is such a large super conventional extrusion ratio, the process control, heating temperature difference, the feed port of the mold, the material, the welding chamber, the reduction in the working process, etc. are all Very high technical requirements, so if it does not have many years of specializing so that such high extrusion is impossible to accumulate more than products.

2. Airtightness

Since the level of a defect in the automotive manufacturing industry is measured by PPM (Parts Per Million), a set of microchannel heat exchanger is about 50 parallel lines, as long as there is a defect (such as porosity, Mixing, etc.), the entire air conditioner will be scrapped, so the quality requirements of parallel flow aluminum flat tube are very high, and the parallel spots produced by a casting rod has a length of nearly 500 meters, pressed by 55m / min. Pressure speed calculation, approximately 9 minutes, during this period, the production line process technology must be absolutely stable, such as mold strength, cast rod temperature, extruded constant temperature isotherm, mold cooling, online spray, etc. As long as there is any slight deviation in any part, it will lead to defects in the product.

3. Ultra-high Dimensional Accuracy

The product dimensional accuracy of the parallel flow tube is quite high in conventional thermal extruded products. At present, since the user requirements are constantly increasing, the size deviation of the width and height of the parallel flow aluminum flat tube has been increased to ± 0.01 ~ ± 0.02 mm.

4. High-quality Casting Technology

The technical specifications of the production parallel aluminum flat tube are very precise. If the purity of the cast material and the amount of hydrogen are not up to standard or there is a very subtle pore or inclusion, it will cause the thin wall of the parallel flow tube to leak. It is conceivable that the quality requirements of the casting technology are extremely high.

5. Surface Spraying Technology

Since the wall thickness of the parallel flow aluminum flat tube is very thin, it is easy to generate leakage due to corrosion under the working conditions of refrigerant medium and external atmospheric corrosion.

In this regard, the thin layer of zinc must be sprayed on its outer surface (usually the zinc layer spray amount is: 10.5 g / m2). And the principle of action is to change its electrode potential, allowing the zinc of the surface has the “sacrificial anode” function. The role is to protect the inner wall of the parallel flow aluminium tube without corrosion.

Since the parallel flow line size is very accurate, it is also very accurate for the combined interface of the spray zinc layer. Only a very small number of devices can be used for the spray zinc operation of the flat tube. CHAL Aluminium Corporation provides perfect surface spraying technology, contact us to obtain a product or technical support.

Producing parallel aluminum flat tube technology is a comprehensive manifestation involving multi-disciplinary, multi-field industrial technology. Not only has to have years of product design experience in this field, but also needs to have multi-disciplinary top technology talent teams and the ability to integrate into various subjects.

CHAL Aluminium Corporation is a supplier of research, development, production and sales of an aluminum micro-channel flat tube, aluminium plates, aluminum tube and other aluminum products. We have advanced and complete equipment for casting, hot rolling, cold rolling, precise rolling, vertical thin-and-thick cutting and tube manufacture, as well as a technical center for research and development. The technical center is capable of inspecting and testing chemical components, mechanical performances and metallographic structures of various materials. In addition, it is also capable of inspection, research and development of such performances as high-temperature, deforming, corrosion and welding, etc. of materials. The complete inspection and testing equipment are sound guarantees for product quality and research and development of materials by our company.