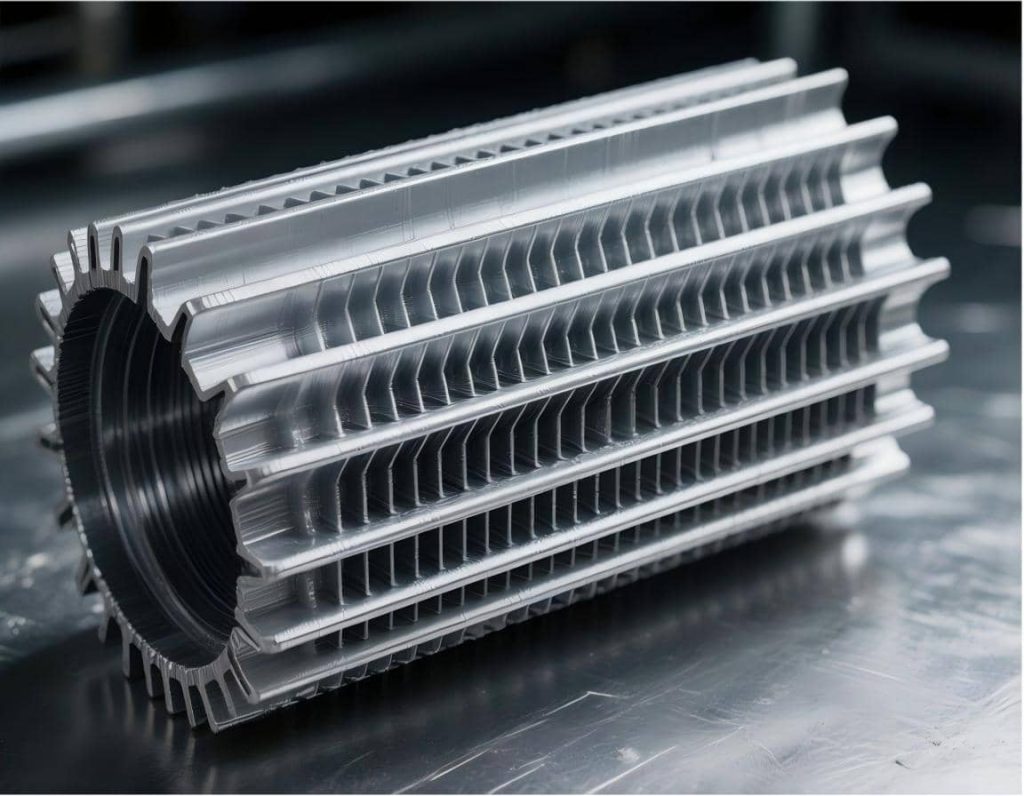

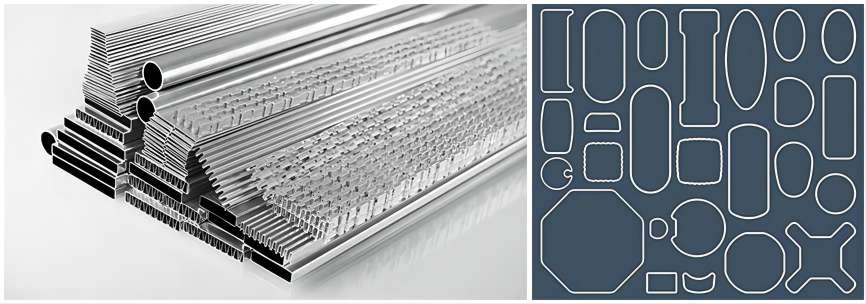

Aluminum high frequency welded pipe (HFW pipe) is a type of seamless pipe that is produced using a high frequency electric current to weld the edges of a flat aluminum strip together. HFW pipe is typically made from alloys such as 6061, 3003, and 5052. In this article, we will explore what aluminum high frequency welded pipe is, its advantages, and the diverse applications it serves.

HFW pipe has a number of advantages over other types of pipe, including:

- Lightweight: Aluminum is one of the lightest metals available, making HFW pipe ideal for applications where weight is a critical factor.

- Strong and durable: HFW pipe is made from strong and durable aluminum alloys, making it able to withstand high pressures and temperatures.

- Corrosion resistant: Aluminum is naturally resistant to corrosion, making HFW pipe ideal for use in harsh environments.

- Formable and weldable: HFW pipe is formable and weldable, making it easy to fabricate into complex shapes.

- Cost-effective: HFW pipe is a cost-effective option for a wide variety of applications.

HFW pipe is used in a wide variety of industries, including:

- Automotive industry: HFW pipe is used to manufacture a variety of automotive components, such as radiators, condensers, and air conditioning coils.

- Aerospace industry: HFW pipe is used to manufacture aircraft components, such as fuel lines, hydraulic lines, and airframes.

- Construction industry: HFW pipe is used to manufacture building materials, such as roofing panels, siding, and gutters.

- Food and beverage industry: HFW pipe is used to transport food and beverages, such as milk, juice, and beer.

- Chemical processing industry: HFW pipe is used to transport corrosive chemicals, such as acids and bases.

- Oil and gas industry: HFW pipe is used to transport oil and gas products, such as crude oil, natural gas, and refined fuels.

- Electrical industry: HFW pipe is used to manufacture electrical components, such as bus bars, cable trays, and conduits.

Factors to Consider When Choosing Aluminum High Frequency Welded Pipe

When choosing aluminum high frequency welded pipe, there are a number of factors to consider, including:

- Alloy type: The alloy type of the HFW pipe will determine its mechanical properties, such as strength, ductility, and corrosion resistance. The most common alloy types used for HFW pipe are 6061, 3003, and 5052.

- Diameter: The diameter of the HFW pipe will determine the flow rate of the fluid or gas being transported. The most common diameters for HFW pipe range from 1/2 inch to 12 inches.

- Thickness: The thickness of the HFW pipe will determine its strength and durability. The most common thicknesses for HFW pipe range from 0.036 inches to 0.120 inches.

- Length: The length of the HFW pipe will depend on the specific application. HFW pipe can be produced in lengths up to 20 feet.

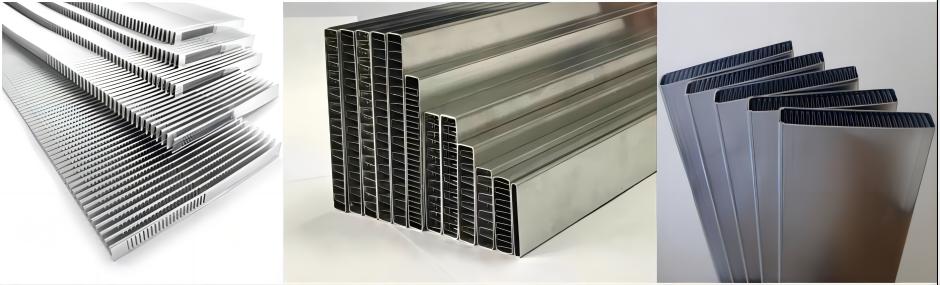

- Surface finish: The surface finish of the HFW pipe can be specified to meet the specific requirements of the application. Common surface finishes include mill finish, anodized, and painted.

- Tolerances: The tolerances of the HFW pipe should be specified to ensure that the pipe will meet the requirements of the application. Common tolerances for HFW pipe include dimensional tolerances and concentricity tolerances.

- Mechanical properties: The mechanical properties of the HFW pipe, such as strength, ductility, and hardness, should be specified to ensure that the pipe will be able to withstand the demands of the application.

- Chemical composition: The chemical composition of the HFW pipe should be specified to ensure that the pipe will be compatible with the fluids or gases being transported.

- Corrosion resistance: The corrosion resistance of the HFW pipe should be specified to ensure that the pipe will be able to withstand the corrosive environment in which it will be used.

- Formability: The formability of the HFW pipe should be specified if the pipe will be bent or formed into complex shapes.

- Weldability: The weldability of the HFW pipe should be specified if the pipe will be welded to other components.

- Cost: The cost of the HFW pipe will depend on the alloy type, diameter, thickness, length, surface finish, tolerances, and mechanical properties.

How to Choose the Right Aluminum High Frequency Welded Pipe for Your Specific Application

When choosing aluminum high frequency welded pipe for a specific application, the following steps should be followed:

- Consider the operating environment. The operating environment of the HFW pipe will determine the alloy type, wall thickness, and surface finish required. For example, if the HFW pipe will be used in a corrosive environment, such as a chemical processing plant, an alloy with high corrosion resistance, such as 6061, should be selected. If the HFW pipe will be used in a high-pressure application, such as a hydraulic system, a thicker wall thickness may be required.

- Determine the required mechanical properties. The mechanical properties of the HFW pipe, such as strength, ductility, and hardness, should be specified to ensure that the pipe will be able to withstand the demands of the application. For example, if the HFW pipe will be used in a high-pressure application, a high-strength alloy should be selected. If the HFW pipe will be bent or formed into complex shapes, a ductile alloy should be selected.

- Select the appropriate alloy type. The alloy type of the HFW pipe will determine its mechanical properties, such as strength, ductility, and corrosion resistance. The most common alloy types used for HFW pipe are 6061, 3003, and 5052.

- 6061 aluminum: 6061 aluminum is a strong and durable alloy that is also highly resistant to corrosion. It is the most common alloy used for HFW pipe.

- 3003 aluminum: 3003 aluminum is a lightweight and ductile alloy that is also resistant to corrosion. It is a good choice for HFW pipe that will be bent or formed into complex shapes.

- 5052 aluminum: 5052 aluminum is a strong and lightweight alloy that is also highly resistant to corrosion. It is a good choice for HFW pipe that will be used in high-strength applications.

- Specify the required dimensions and tolerances. The dimensions and tolerances of the HFW pipe should be specified to ensure that the pipe will meet the requirements of the application. Common dimensions and tolerances for HFW pipe include the outer diameter, inner diameter, wall thickness, and length.

- Consider the surface finish requirements. The surface finish of the HFW pipe can be specified to meet the specific requirements of the application. Common surface finishes for HFW pipe include mill finish, anodized, and painted.

- Evaluate the cost. The cost of the HFW pipe will depend on the alloy type, diameter, thickness, length, surface finish, tolerances, and mechanical properties. It is important to evaluate the cost of different HFW pipe options before making a selection.

Conclusion

Aluminum high frequency welded pipe (HFW pipe) is a versatile and durable material that can be used in a wide variety of applications. It is important to carefully consider the operating environment, required mechanical properties, alloy type, dimensions and tolerances, surface finish requirements, and cost when choosing HFW pipe for a specific application. By selecting HFW pipe from a reputable aluminum pipe manufacturer that meets high quality standards and comes with a warranty, you can ensure that the pipe will perform reliably for many years to come.