Aluminum alloy materials have low density, high strength, high thermal conductivity, strong corrosion-resistance, and excellent physical and mechanical properties, so aluminum sheets and aluminum tubes, etc. are widely used in welding structures of industrial products. Due to improper welding methods and welding process parameters, aluminum alloy parts have been seriously deformed due to excessive stress concentration after welding, or because of defects such as pores, slag inclusion, and incomplete penetration in the weld, resulting in weld metal cracks or material cracks looseness seriously affects product quality and performance.

Features of Aluminum Alloy

Aluminum is a silver-white light metal with good plasticity, and high electrical and thermal conductivity, and also has the ability to resist oxidation and corrosion. Aluminum is easily oxidized to produce aluminum oxide film, and inclusions are easily generated in the weld, which can destroy the continuity and uniformity of the metal and reduce its mechanical properties and corrosion resistance.

Difficulties of Aluminum Alloy Welding

- Easy to oxidize

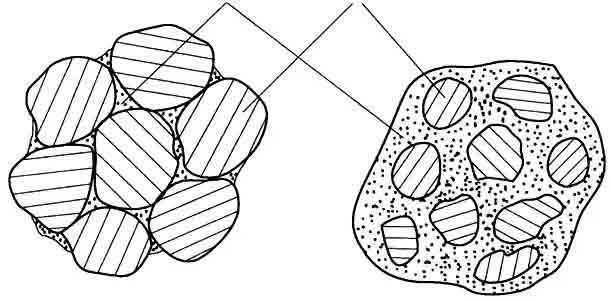

Aluminum is easily combined with oxygen to form a dense Al2O3 film (thickness about 0.1-0.2 μm) with a high melting point (about 2050 °C), far exceeding the melting point of aluminum and aluminum alloys (about 600 °C or so). The density of aluminum oxide is 3.95-4.10g/cm3, which is about 1.4 times that of aluminum. The surface of the aluminum oxide film is easy to absorb moisture. When welding, it hinders the fusion of basic metals, and it is easy to cause defects such as pores, slag inclusions, leading to the performance of the weld decline.

- Easy to generate stomata

The main reason for the formation of pores when welding aluminum and aluminum alloys are hydrogens. Liquid aluminum can dissolve a large amount of hydrogen, while solid aluminum hardly dissolves hydrogen. Therefore, when the molten pool temperature cools and solidifies rapidly, hydrogen cannot escape in time, and it is easy to be welded and gather in the seam to form pores. At present, it is difficult to completely avoid hydrogen holes. There are many sources of hydrogen, such as hydrogen in the arc welding atmosphere, and moisture in the air adsorbed on the surface of the aluminum plate and welding wire. The practice has proved that even if the purity of argon gas reaches more than 99.99% according to the GB/T4842 standard when the moisture content reaches 20ppm, plenty of dense pores will appear. When the relative humidity of the air exceeds 80%, there will be apparent stomata.

- High tendency for weld deformation and crack formation

The linear expansion coefficient and crystallization shrinkage rate of aluminum are about twice larger than those of steel, which is easy to produce large internal stress of welding deformation and will promote the generation of hot cracks for structures with high rigidity.

- The thermal conductivity of aluminum is large (pure aluminum 0.538 cal/Cm.s.℃), which is about 4 times that of steel. Therefore, when welding aluminum and aluminum alloys, consumes more heat than welding steel.

- Evaporative Burn Loss of Alloying Elements.

Aluminum alloys contain low boiling point elements (such as magnesium, zinc, manganese, etc.), which are easily evaporated and burned under the action of high-temperature arcs. Therefore, the chemical composition of the weld metal is changed and reduces the performance of the weld.

- High temperature strength and low plasticity

At high temperatures, the strength and plasticity of aluminum are low, which destroys the formation of weld metal, and sometimes easily causes weld metal slump and weld penetration.

- No color change

When aluminum and aluminum alloys change from solid to liquid, there is no obvious color change, making it difficult for operators to grasp the heating temperature.

Processes of Aluminum Alloy Welding

- Preparation Before Welding

Strictly clean the surface oxide film on both sides of the weld groove with chemical or mechanical methods. Chemical cleaning is the use of alkali or acid to clean the surface of the workpiece, which can not only remove the oxide film but also remove oil. The surface of the aluminum alloy after washing is matt silver-white. Chemical cleaning is the use of alkali or acid to clean the surface of the workpiece, which can not only remove the oxide film but also remove oil. And the surface of the aluminum alloy after washing is matt silver-white.

Mechanical cleaning can use pneumatic or electric milling cutters, scrapers, files, and other tools. For thinner oxide films, 0.25mm copper wire brushes can also be used to polish and remove oxide films. Welding should be carried out immediately after cleaning. If it is placed for more than 4 hours, it should be cleaned again.

- Determine Assembly Clearance and Weld Spacing

During the welding process, the aluminum plate is thermally expanded, resulting in a reduction in the gap of the weld groove. If the assembly gap before welding is too small, the grooves of the two plates will overlap during the welding process. Therefore, it will cause unevenness and deformation of the board surface after welding. On the contrary, if the assembly gap is too large, it will be difficult to weld, and there is a possibility of burn-through. Appropriate tack welding spacing can ensure what we need. Therefore, it is an effective measure to reduce deformation for appropriate assembly gap and welding spacing.

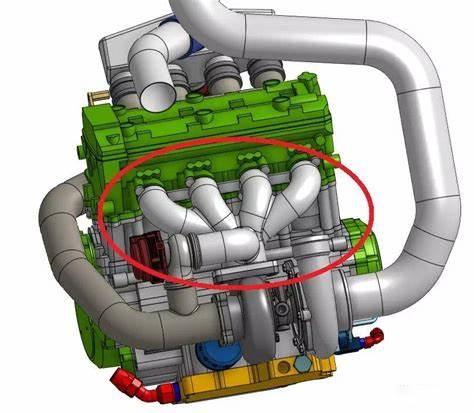

- Equipment of Aluminum Alloy Welding

At present, there are many types of welding products on the market. Generally, AC tungsten argon arc welding (ie TIG welding) should be used. It is a welding method that uses the arc generated between the tungsten electrode and the workpiece to melt the base metal and fill the welding wire under the protection of argon gas. When the welding machine operates, the polarity of the alternating current changes periodically. In each cycle, the half-wave is DC positive connection, and another is DC reverse connection. During the positive half-wave period, the tungsten electrode can emit enough electrons without overheating, which is beneficial to the stability of the arc. The oxide film formed on the surface of the workpiece during the reverse half-wave period is easily removed to obtain a bright, beautiful, and well-formed weld.

- Welding Wires

Generally, 301 pure aluminum and 311 aluminum silicon are used as welding wires.

- Methods and Parameters

When the welding wall thickness is more than 3mm, a V-shaped groove is formed and the angle is 60°~70°. In addition, the gap should not be greater than 1mm, and it is completed by multi-layer welding. When the wall thickness is below 1.5mm, no grooves, no gaps, and no filler wires are added. When welding fixed pipe butt joints, when the pipe diameter is 200mm and the wall thickness is 6mm, a tungsten electrode with a diameter of 3-4mm should be used. This can be completed with a welding current of 220-240A, a filler wire with a diameter of 4mm, and 1-2 layers of tungsten electrodes.