Aluminum offers a multitude of benefits, including being lightweight and having high corrosion resistance. It comes in the form of plates or sheets, both of which can continuously be recycled without any loss of properties and can be used for a wide array of industrial applications.

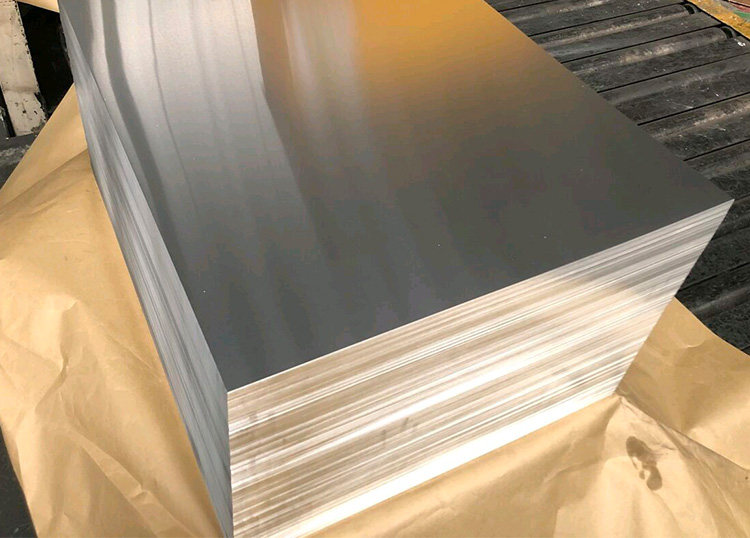

What are Aluminum Sheets?

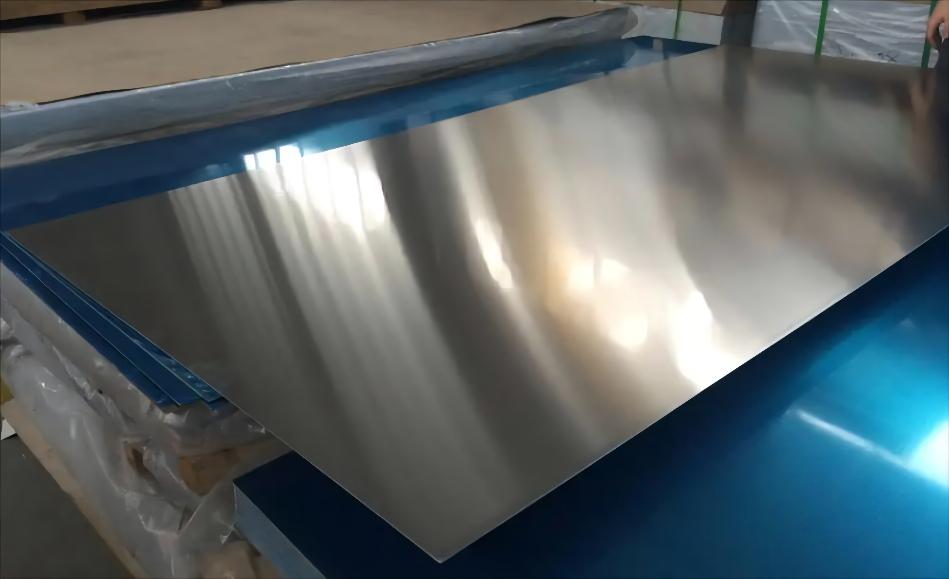

The sheet is the form of aluminum that is used the most often. You can find it in all of the major markets of the aluminum industry. For instance, the aluminum sheet is useful for manufacturing packages and cans in the packaging industry. It is also valuable for manufacturing tractor-trailers and automobile body panels in the transportation industry. Sheets are also useful for cookware and home appliances, as well as for construction/building products, such as carports, awnings, roofing, gutters, and siding.

Sheet aluminum can even be given blue, red, gold, or black colors, for instance, through color anodizing. It can also be etched to feature a matte finish or polished to feature a bright, sparkling appearance. Aluminum sheets may additionally be made to resemble wood through texturing.

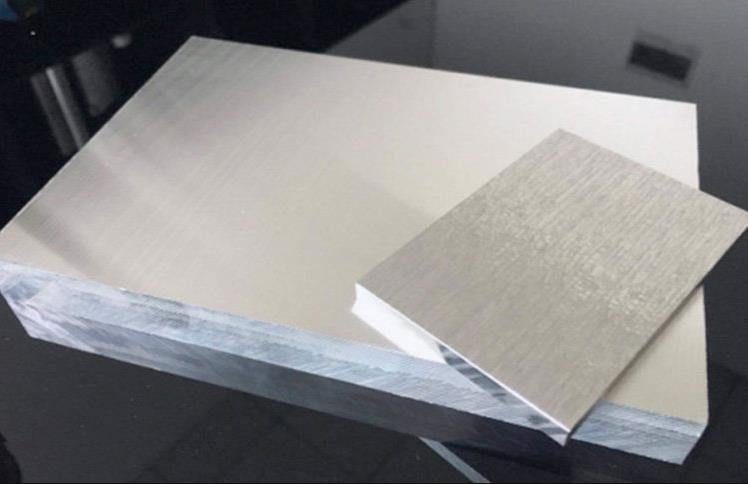

What are Aluminum Plates?

Aluminum plate is the most often used for heavy-duty applications, particularly in the transportation product manufacturing, aerospace, and military industries. Since certain aluminum alloys have the potential to become more durable at extremely cold temperatures, Aluminum Plates serve as the skin of spacecraft fuel tanks and jets, and can also be useful for storage tanks. Moreover, you can use Aluminum plates in the manufacture of structural sections used in ships and railcars and for military vehicle armor.

Plates VS. Sheets

We often use the words plate and sheet to distinguish the thickness of metal. While plate metal is thicker than 3 mm, sheet metal is less than 3 mm thick. There is no need to be confused, as the differences between classifications like “plate,” “sheet,” “foil,” and others are spelled out. Words like plate and sheet are typically related to the metal aluminum.

The product’s thickness determines which category it belongs to. A sheet has a thickness of 0.006 inches or more but less than 0.25 inches, whereas a plate has a thickness of greater than or equal to 0.25 inches. A foil with a thickness of fewer than 0.006 inches sits at the extreme of this spectrum. These 3 categories make up the majority of the aluminum used in various industries. Under intense pressure, aluminum is forced between rolls to make it longer and thinner in the direction of motion. Which of the three categories the resultant aluminum product will fall under depends on the amount of pressure used. Aluminum can be formed into the required shape and size by repeatedly rolling the material. As soon as we obtain the desired gage or thickness of aluminum, the rolling operation is terminated.

Aluminum Plates VS. Aluminum Sheets

The sheet form is the most often used in aluminum. The aluminum sheet is widely utilized in packaging-related container types except in the aerospace industry. Additionally, it is frequently used in building materials such as siding, awnings, roofs, gutters, and carports, as well as in tractor-trailers, vehicle body panels, cookware, and appliances.

Aluminum sheets can be given a matte finish by color anodizing, etched for matte finishes, or a reflecting finish, which is often used in aircraft applications.

In the aerospace, transportation, and military sectors, aluminum plates are most frequently utilized for heavy-duty applications. Certain aluminum alloys have the unusual property of strengthening at very low temperatures. As a result, the skin of spaceship fuel tanks, jets, and storage tanks is made of aluminum plates.

Additionally, the aluminum plate is frequently used for the structural components of ships and cars, as well as for the armor of military vehicles and even body armor, due to its strong resistance to corrosion, lightweight, and high strength.

As aluminum moves between rolls under pressure, it becomes longer and thinner, thus resulting in Aluminum Plates or sheets. One of the main differences between Aluminum Plate and sheets is that sheet metal is under .249” thick, while plate metal is .250” and above. Another difference between Aluminum plates and sheets has to do with the distinct applications for which they are used.

Same Benefits of Aluminum Sheets and Plates

- Light in Weight

An aluminum sheet is one of the lightest metal sheets on the market which weighs around one-third as little as a steel sheet. What is more, reduce of structure weight is vital for cost, it also makes the sheet easier to handle.

- Resistant To Corrosion

In many environments and industrial settings, corrosion is an issue. One of those materials that resist corrosion is aluminum. Some alloys of aluminum sheets are more resistant to corrosion than others, and it takes very strong, aggressive corrosive forces to create corrosion in aluminum sheets.

- Strength

Aluminum sheet metal is robust while still being lightweight. It is helpful in industrial applications due to its strength and lightweight quality. For forces and stresses generated in structural applications, it is a useful and effective shape.

- Formability

Aluminum sheet metal has a rather low melting point. As a result, when exposed to a specific amount of heat, it may be easily shaped into a variety of shapes.

- Reflectivity

Due to its reflectivity, which means that it reflects light and heat away from its surface, aluminum sheet metal is perfect for applications involving lighting.

- Fireproof

Aluminum sheet metals are resistant to burning when exposed to fire; only a thin layer of the sheet metal is harmed. Additionally, aluminum sheet metal does not produce hazardous gas when subjected to high heat.

4 benefits of using aluminum sheet metal

Regardless of how exciting it is to work on a DIY or home improvement project, decisions have to be made. One of which is to choose the material. It plays a great role in the project as it is the most crucial aspect as every factor affecting the success of your project is dependent upon the selected metal. If the selection is inappropriate, every effort made for it goes in vain.

Aluminum is such a natural earth-based element that is being used in a vast variety of our daily lives. Would you like to know why aluminum sheet metal stands out over other metals? Then keep on reading.

Here are some properties and benefits of aluminum sheet metal.

Light in Weight

Aluminum is a very light metal, about a third of steel or stainless steel. Aluminum is being used in many areas of our daily lives. For example, it is being used in vehicles, which reduces the weight of a car substantially while maintaining stability and load capacity.

Resistant To Corrosion

Corrosion is a common issue of any metal. No matter how strong the metal is, there are chances to get corrosion when it comes in contact with oxygen in the air. With aluminum, this is slightly different. Aluminum naturally generates a protective oxide coating and is therefore highly corrosion-resistant.

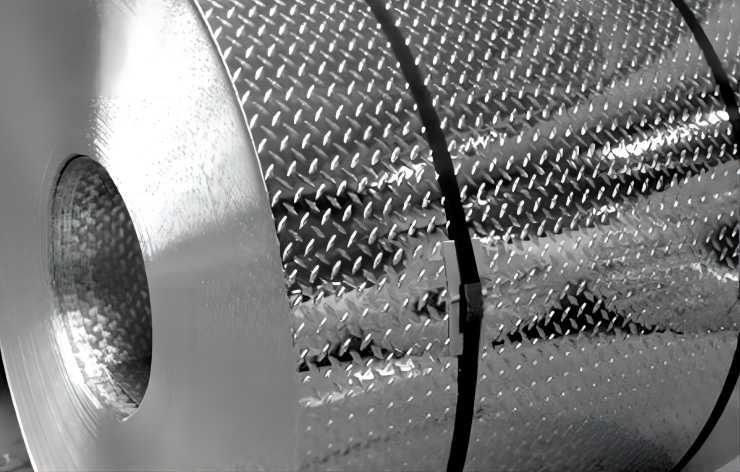

This feature makes it perfect for using it in almost any construction project. There are different finishes available one of the most used are the mill finish and the aluminum diamond plate. Aluminum diamond plate is often used for pickups and trucks but also as floor plates or ramps or as steps as it can prevent from slipping when wet.

Ductile

Aluminum has an amazing feature of ductility. It has a low melting point and density that makes it easy as a fabricator to work with. Once it has been melted, you can bend or create a shape in any form. Be it thinning or stretching, everything is possible while working with aluminum. This feature of the sheet metal makes it accurate to create different product’s design without any hassle.

Reflectivity

Aluminum is a good reflector of visible light as well as heat, and that together with its low weight, makes it an ideal material for reflectors in, for example, light fittings or rescue blankets.

Recyclability

Aluminum is 100 percent recyclable with no downgrading of its qualities. The re-melting of aluminum requires little energy: only about 5 percent of the energy required to produce the primary metal initially is needed in the recycling process.

Apart from the above-mentioned characteristics, aluminum is impermeable and odorless which makes it appropriate for using it for food and beverages.

Conclusion

The gauge of aluminum plates and sheets determines their thickness (thickness). Generally speaking, a sheet is thinner than a plate. Aluminum sheets range in thickness from 0.5 mm to 6.0 mm; anything thicker than 6.0 mm is referred to as a plate.

With a solid reputation for producing high-quality aluminum products, CHAL manufactures a variety of aluminum plates and sheets to suit all kinds of applications.