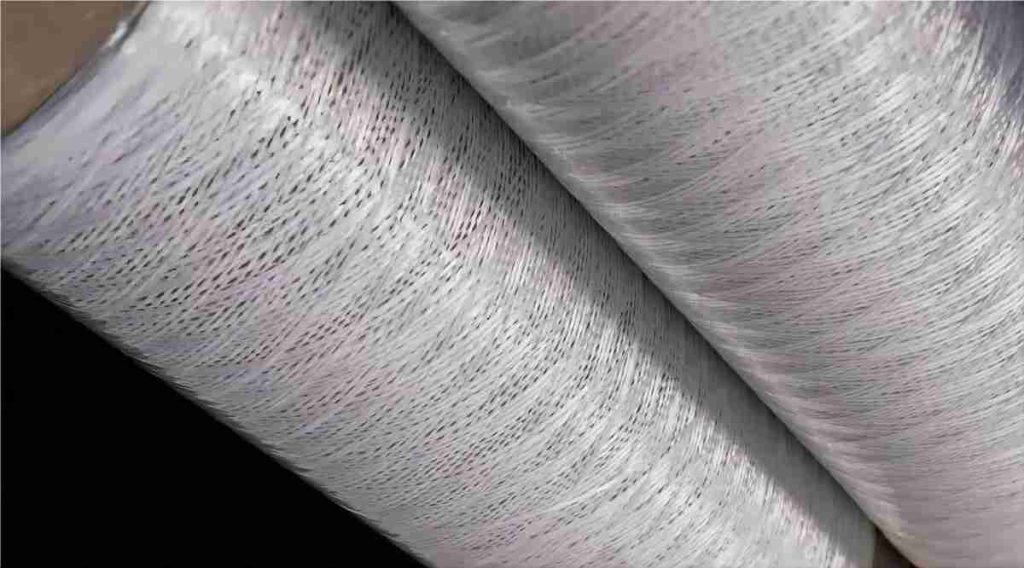

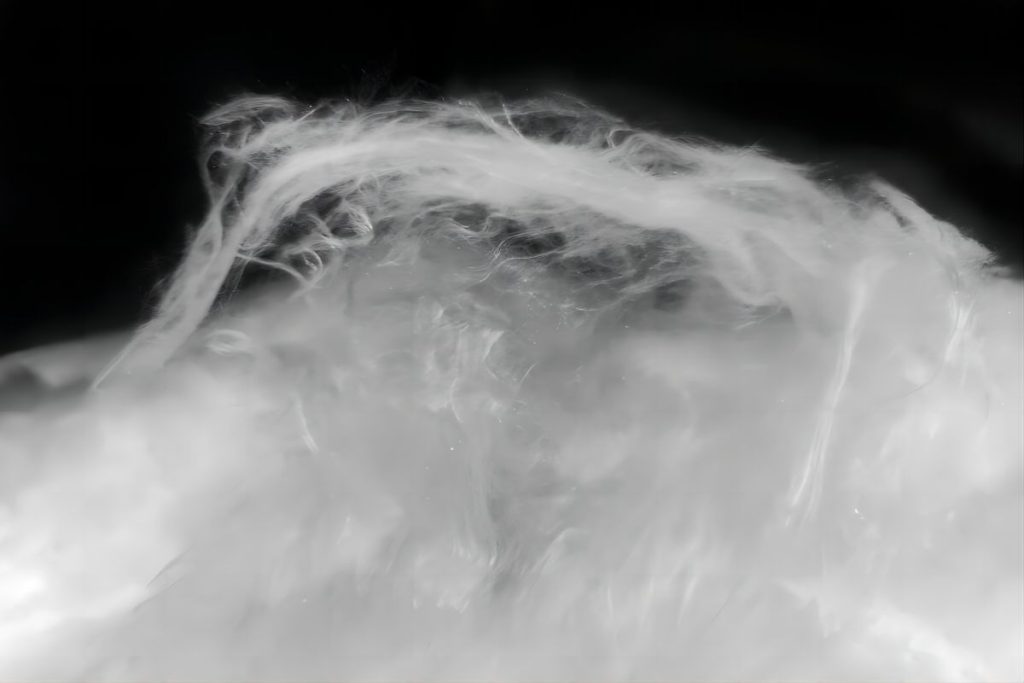

Ceramic fibers are a versatile material that is used in a wide variety of applications. They are characterized by their high strength, high temperature resistance, and chemical inertness. Ceramic fibers are made from a variety of materials, including alumina, silica, and mullite. The type of ceramic fiber that is used will depend on the specific requirements of the application.

In this article, we will discuss the three main types of ceramic fibers: aluminum silicate fiber, mullite fiber, and alumina fiber, discuss the applications of ceramic fibers, and how to choose the right type of ceramic fiber for a particular application.

Types of Ceramic Fibers

There are many different types of ceramic fibers, but the three main types are:

- Aluminum silicate fiber: This type of fiber is made from a mixture of alumina and silica. It is the most common type of ceramic fiber, and it is used in a wide variety of applications. Aluminum silicate fibers have a melting point of around 1,500 degrees Celsius, and they are resistant to a variety of chemicals. They are also relatively inexpensive, which makes them a popular choice for many applications.

- Mullite fiber: This type of fiber is made from a mixture of alumina and silica, with a small amount of mullite. Mullite is a naturally occurring mineral that is formed when alumina and silica are heated to high temperatures. Mullite fibers have a melting point of around 1,800 degrees Celsius, and they are more resistant to thermal shock than aluminum silicate fibers. They are also more resistant to acids and bases. However, mullite fibers are more expensive than aluminum silicate fibers.

- Alumina fiber: This type of fiber is made from pure alumina. It has the highest melting point of the three types of ceramic fibers, at around 2,000 degrees Celsius. Alumina fibers are also the most resistant to chemical attack. However, they are also the most expensive type of ceramic fiber.

Applications of Ceramic Fibers

Ceramic fibers are used in a wide variety of applications, including:

- High temperature insulation: Ceramic fibers are used to insulate high temperature equipment, such as furnaces, ovens, and boilers. They are also used in the aerospace industry to insulate jet engines and rocket motors. Ceramic fibers are effective insulators because they have a high thermal conductivity. This means that they can transfer heat very efficiently, which helps to keep the equipment from overheating.

- Filter material: Ceramic fibers are used to make filters for a variety of applications, including air filtration, water filtration, and oil filtration. They are also used in the electronics industry to make filters for electronic components. Ceramic fibers are effective filters because they have a high surface area. This means that they can trap a large number of particles, which helps to improve the quality of the filtered material.

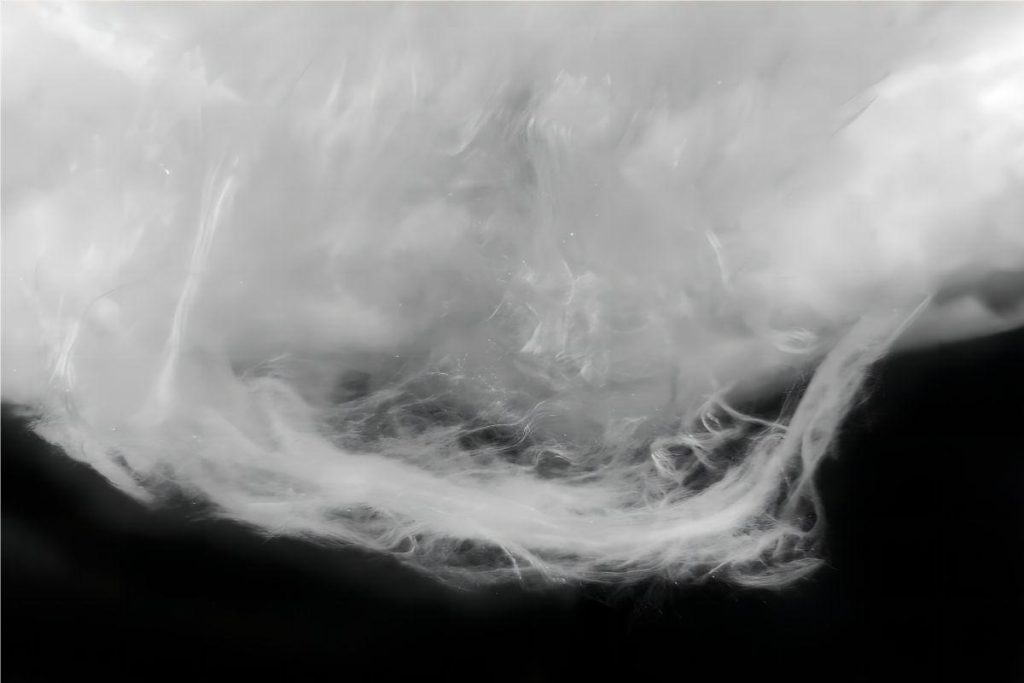

- Sound absorbing and insulating materials: Ceramic fibers are used to make sound absorbing and insulating materials. These materials are used in a variety of applications, including automotive interiors, building insulation, and noise barriers. Ceramic fibers are effective sound absorbers because they have a high density. This means that they can absorb sound waves very effectively, which helps to reduce noise levels.

How to Choose the Right Type of Ceramic Fibers?

The right type of ceramic fiber for a particular application will depend on the specific requirements of the application. Some factors to consider when choosing ceramic fibers include:

- The temperature range: Ceramic fibers have a wide range of temperature resistance. The type of fiber that is chosen will depend on the maximum temperature that the fiber will be exposed to. For example, if the application requires insulation at temperatures up to 1,500 degrees Celsius, then aluminum silicate fiber would be a good choice. However, if the application requires insulation at temperatures up to 2,000 degrees Celsius, then alumina fiber would be a better choice.

- The chemical resistance: Ceramic fibers are resistant to a variety of chemicals. However, some fibers are more resistant to certain chemicals than others. The type of fiber that is chosen will depend on the chemicals that the fiber will be exposed to. For example, if the application requires insulation in an environment that is corrosive to aluminum, then mullite fiber would be a good choice.

- The mechanical properties: Ceramic fibers have a variety of mechanical properties, such as strength, stiffness, and toughness. The type of fiber that is chosen will depend on the mechanical requirements of the application. For example, if the application requires a fiber that is strong and stiff, then alumina fiber would be a good choice. However, if the application requires a fiber that is tough and resistant to breaking, then mullite fiber would be a better choice.

Summary

Ceramic fibers are a versatile material that is used in a wide variety of applications. They are characterized by their high strength, high temperature resistance, and chemical inertness. When choosing ceramic fibers, it is important to consider the specific requirements of the application.

In addition to the three main types of ceramic fibers discussed above, there are a number of other types of ceramic fibers that are available. These include zirconia fibers, boron fibers, and silicon carbide fibers. Each of these types of fibers has its own unique properties, and they are used in different applications.

Ceramic fibers are a valuable material that has a wide range of applications. As the demand for high temperature materials continues to grow, the use of ceramic fibers is likely to increase in the future.

We hope that this article will provide you with a better understanding of ceramic fibers and their applications. If you have any questions, please feel free to contact us.