In the ever-evolving world of automotive engineering, innovation is the driving force behind improvements in fuel efficiency, safety, and overall performance. One of the latest and most promising innovations on the horizon is the use of aluminum fiber composites in vehicle manufacturing. These advanced materials have the potential to revolutionize the automotive industry by making vehicles lighter, stronger, and more efficient. In this article, we will delve into the transformative power of aluminum fiber composites and their potential to reshape the automotive landscape.

The Current State of the Automotive Industry

The automotive industry is at a pivotal juncture, facing numerous challenges and opportunities. With environmental concerns and stringent emissions regulations at the forefront, automakers are under immense pressure to produce vehicles that are more fuel-efficient and environmentally friendly. Simultaneously, consumers are demanding vehicles that offer better performance, safety, and comfort.

One of the most pressing challenges for the industry is the need to reduce vehicle weight. This is driven by the understanding that lighter vehicles are more fuel-efficient and produce fewer emissions. The quest for lightweight materials has led to the exploration of various alternatives to traditional steel, and aluminum fiber composites have emerged as a frontrunner in this endeavor.

Advantages of Aluminum Fiber Composites

Aluminum fiber composites offer a multitude of advantages over other materials commonly used in automotive manufacturing. These advantages are instrumental in addressing the industry’s current challenges and aligning with the desires of both automakers and consumers.

Exceptional Lightweight Properties

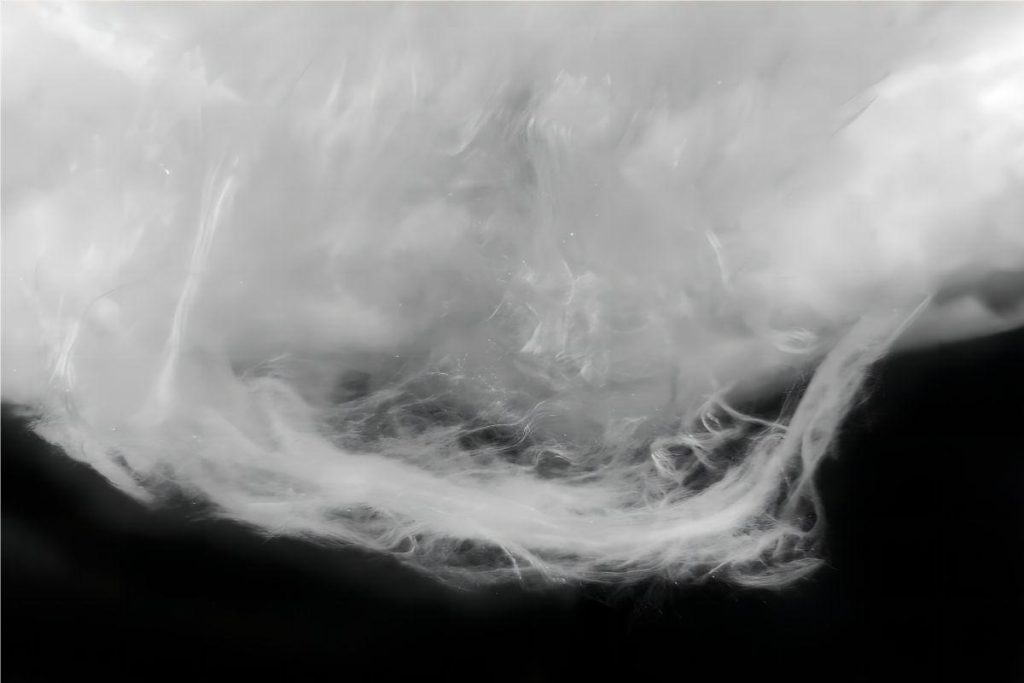

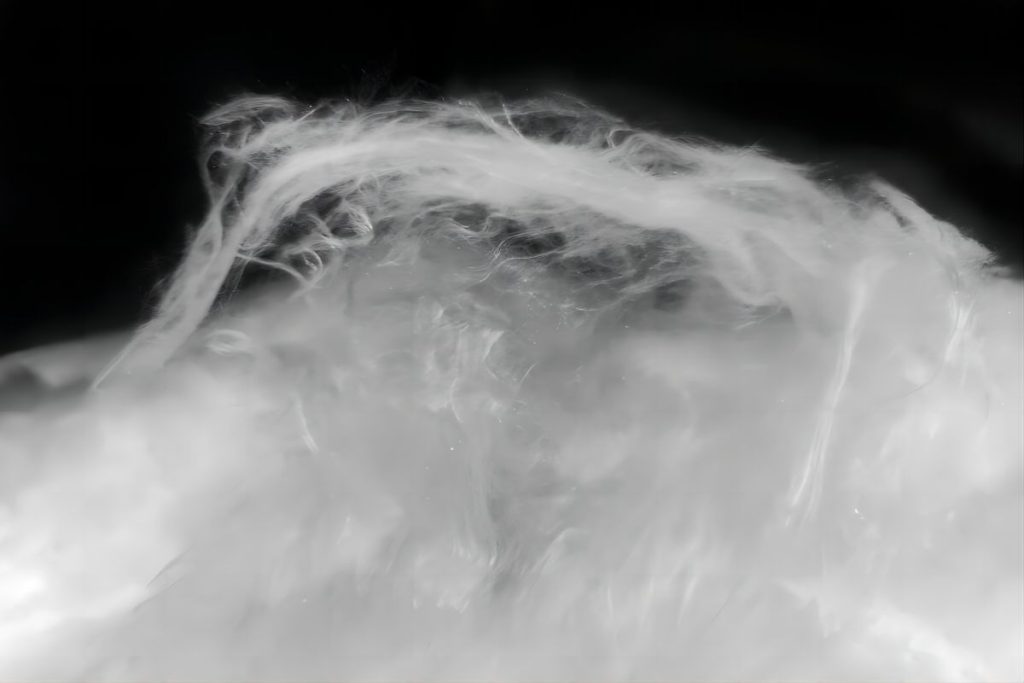

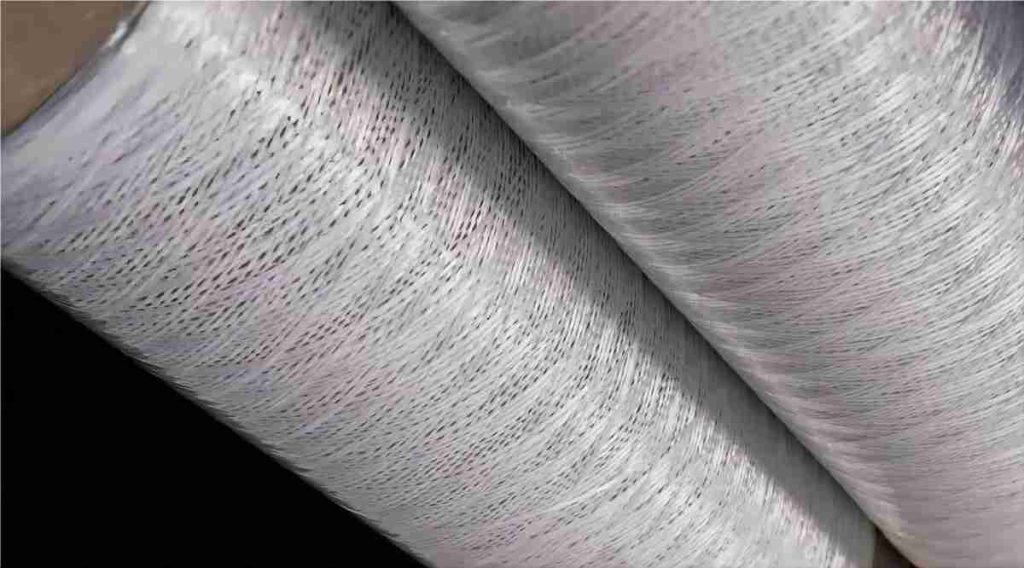

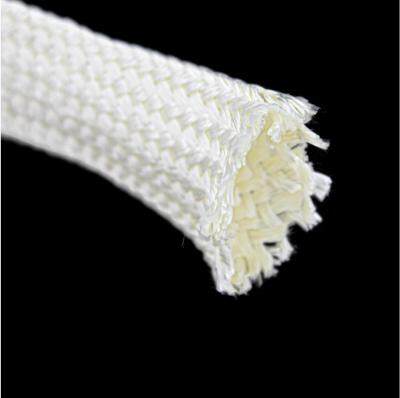

Aluminum fiber composites are renowned for their remarkable lightweight properties. They combine the inherent lightness of aluminum with the strength and stiffness of embedded carbon or glass fibers. As a result, these composites are significantly lighter than traditional steel, making them an ideal choice for vehicle manufacturing.

- Lightweight materials are vital for several reasons

- Fuel Efficiency: Lighter vehicles require less energy to propel, resulting in improved fuel efficiency. As automakers strive to meet stricter fuel economy standards, reducing weight is crucial.

- Emissions Reduction: Reduced vehicle weight translates to lower emissions. This not only benefits the environment but also helps manufacturers comply with stringent emissions regulations.

- Enhanced Performance: Lighter vehicles exhibit improved acceleration, handling, and overall performance, delivering a superior driving experience.

- Strength, Stiffness, and Durability

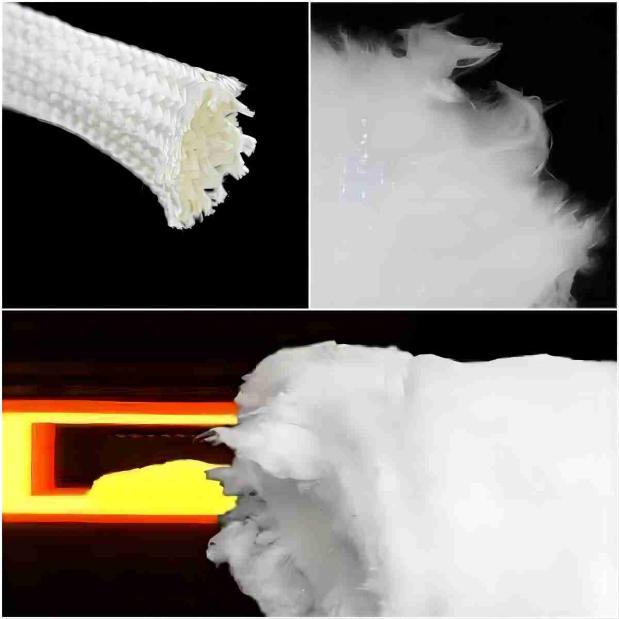

Aluminum fiber composites are engineered to possess exceptional strength, stiffness, and durability. The combination of aluminum with reinforcing fibers creates a material that can withstand high levels of stress while maintaining structural integrity. This robustness opens the door to innovative design possibilities and improved safety features in vehicles.

- Safety: Stronger materials can be used to reinforce critical structural components, making vehicles more crash-resistant and enhancing occupant safety.

- Design Flexibility: The increased strength and stiffness of aluminum fiber composites allow for more innovative and efficient vehicle designs, optimizing space utilization and reducing material waste.

- Sustainability

In an era of heightened environmental awareness, sustainability has become a central concern for both automakers and consumers. Aluminum fiber composites contribute positively to sustainability efforts in several ways:

- Reduced Fuel Consumption: The lightweight nature of these composites directly correlates with reduced fuel consumption over a vehicle’s lifetime, contributing to a cleaner environment.

- Recycling Potential: Aluminum is highly recyclable, and the incorporation of aluminum fiber composites in vehicles could promote greater recycling efforts, further reducing the industry’s environmental footprint.

- Sustainable Sourcing: Aluminum used in these composites can be sourced from sustainable and responsible suppliers, aligning with the automotive industry’s sustainability goals.

The Properties of Aluminum Fiber Composites

To fully appreciate the potential of aluminum fiber composites in the automotive industry, it’s essential to understand their properties in more detail.

- Strength

Aluminum fiber composites are incredibly strong due to the inclusion of reinforcing fibers, such as carbon or glass. This added strength allows for the construction of lightweight, yet robust, vehicle components that can withstand heavy loads and stresses.

- Stiffness

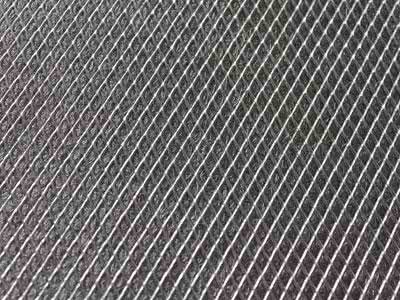

These composites exhibit high stiffness, making them ideal for structural applications. Components like chassis parts and suspension systems can benefit from this stiffness, resulting in improved vehicle handling and safety.

- Lightweight

The low density of aluminum combined with the lightweight reinforcing fibers results in materials that are significantly lighter than steel. This is a crucial factor in achieving better fuel efficiency and reducing emissions.

- Corrosion Resistance

Aluminum has inherent corrosion resistance, which helps ensure the longevity of vehicle components. This resistance to rust and corrosion is particularly valuable for structural elements exposed to harsh environmental conditions.

Using Aluminum Fiber Composites for Fuel Efficiency

One of the most prominent applications of aluminum fiber composites in the automotive industry is their use in achieving superior fuel efficiency. The reduction in vehicle weight directly correlates with improved fuel economy, making these composites an attractive choice for automakers.

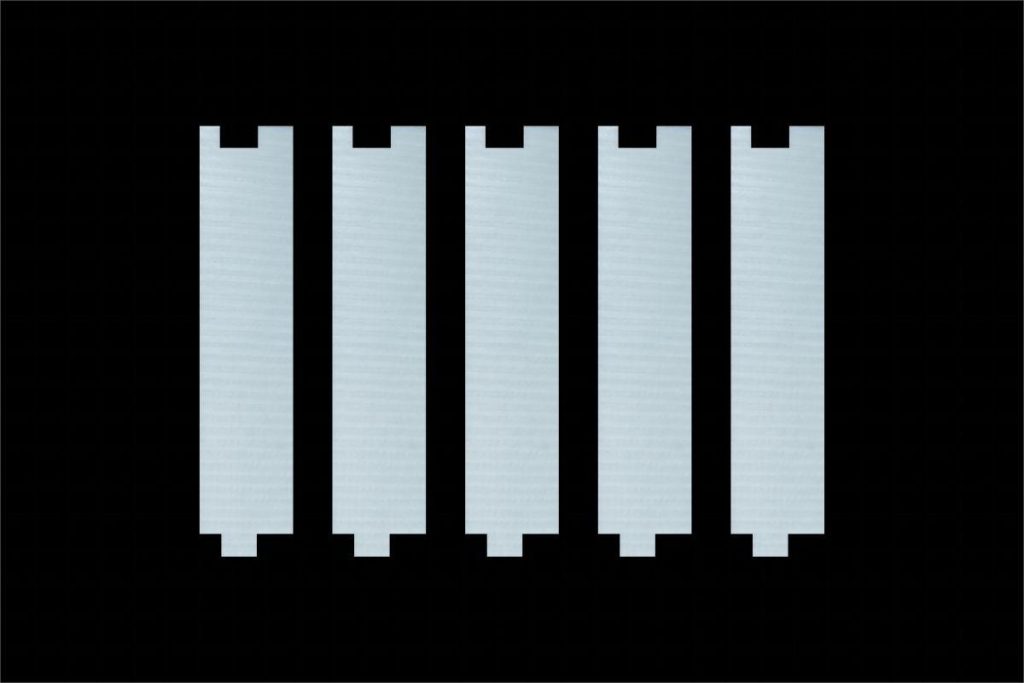

- Body Panels

The body of a vehicle contributes significantly to its overall weight. By replacing traditional steel body panels with aluminum fiber composite alternatives, automakers can reduce weight without compromising safety or structural integrity.

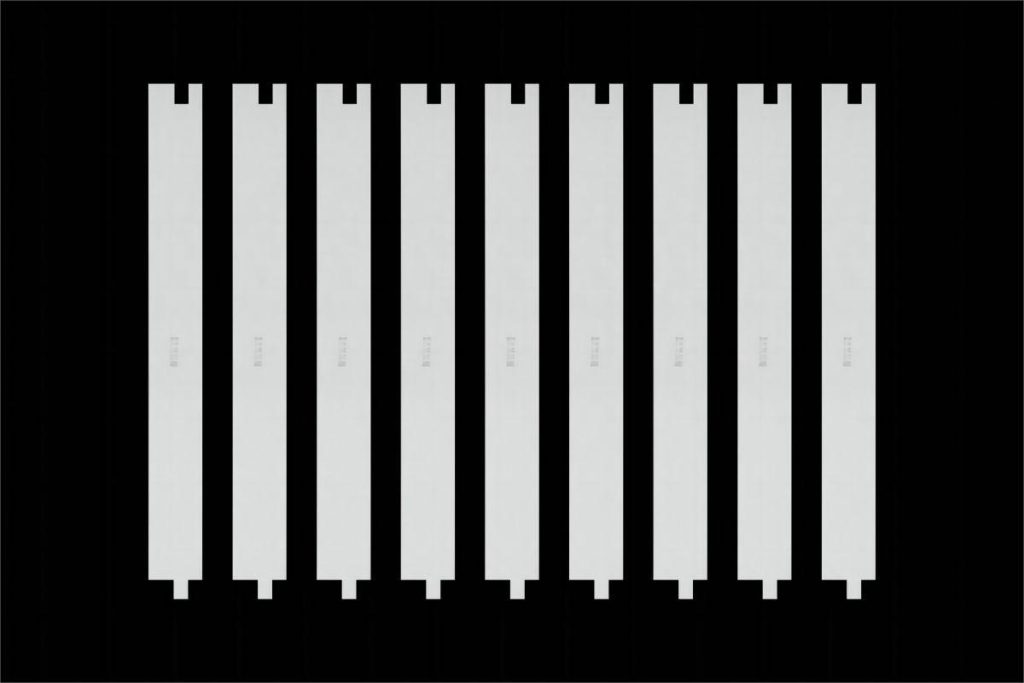

- Chassis Components

Chassis components, including subframes and suspension parts, can also benefit from the lightweight properties of these composites. A lighter chassis translates to better handling, reduced energy consumption, and enhanced performance.

- Drive Trains

Incorporating aluminum fiber composites in the manufacturing of drivetrain components, such as transmission casings and engine parts, can further reduce weight and improve overall efficiency. This leads to reduced fuel consumption and emissions.

- Interior Components

Even interior components like seats and trim panels can be designed using these advanced materials, contributing to overall weight reduction and a more fuel-efficient vehicle.

Conclusion

Aluminum fiber composites have emerged as a transformative force in the automotive industry. Their exceptional lightweight properties, combined with strength, stiffness, and sustainability, position them as promising materials for the future of vehicle manufacturing. As automakers and consumers alike place greater emphasis on fuel efficiency, safety, and environmental sustainability, these composites offer a viable solution to address these evolving needs.

In summary, aluminum fiber composites represent a significant leap forward in automotive engineering. Their potential to make vehicles lighter, more fuel-efficient, and environmentally friendly is poised to revolutionize the industry. As research and development efforts continue to refine these materials and integrate them into mainstream vehicle production, the automotive landscape is set to undergo a dramatic and beneficial transformation.