Aluminum Profiles For Window and Door System

- Customizing is available as you offer us the section drawings.

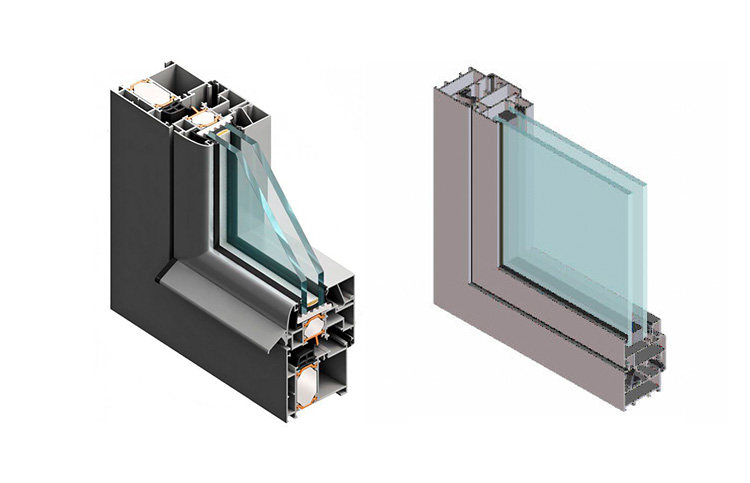

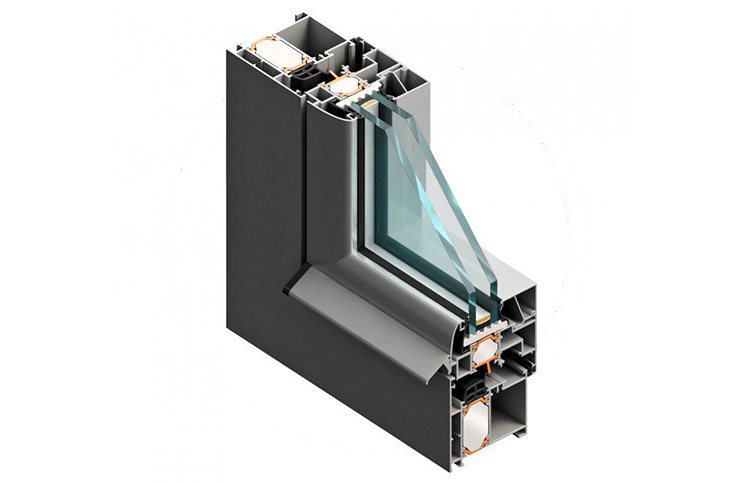

- Two kinds of profiles: non-thermo-break profiles and thermo-break profiles.

- Surface finish: mill finish, anodizing, electrophoresis, powder coating, wood grain, PVDF.

- Property: sound isolation, heat preservation.

- Saving energy.

Brief Introduction of Aluminum Profiles For Window and Door System

The aluminum window and door profile are made from a material that does not warp or rust, and hence can be used in outdoor settings as well as indoors. Due to the low thermal conductivity, this aluminum profile for mosquito screens, doors, and windows are sustainable and resistant to weather changes. The aluminum profile can be used in a large number of residential, commercial, and industrial applications. These include door and window frames, sliding door sills, and window stiffeners.

Specification Of Aluminum Profiles For Window and Door System

- Customizing is available as you offer us the section drawings

- Two kinds of profiles: non-thermo-break profiles and thermo-break profile

- Surface finish: mill finish, anodizing, electrophoresis, powder coating, wood grain, PVDF

- Property: sound isolation, heat preservation

- Saving energy

- Certificates: SGS, SONCAP, ISO9001: 2008, ASTM

- Colors: Brown, red, white, champagne, or Customized

- Shape: Square, round, hollow, triangle, or Customized

Advanced Surface Treatment of Aluminum Profiles For Window and Door System

Powder Coating

Powder coating is a safe, dry finishing process that uses finely ground particles of pigment and resin to create a protective finish. We choose to powder coat our steel frames because it is low in toxicity and has low flammability. The powder coating is then evenly melted and cooled into a thin, durable film. Powder coating can maintain its finish for up to 15-20 years, depending on pre-treatment and the type of powder. Its resistance to weather, corrosion, and chemicals makes powder coating a more durable finish than paint or other liquid coatings.

Wood Grain

Ceilings, cladding, curtain walls, and partitions with aluminum wood finish are often seen in commercial buildings. In-home interior decoration, wood-like aluminum doors, and windows are prevalent now, and aluminum furniture cabinets with wood grain color have begun the market. Now you can see many wood colors in garden design, like fencing and gates, decking, house siding, and railing.

Anodizing

Anodizing cannot peel off. The coating is part of the metal. Anodizing gives aluminum a deeper, richer metallic appearance than is possible with organic coatings. This is because an anodized coating is translucent, and one can see the base metal underneath the coating. Anodizing provides a thin aluminum oxide layer, which will deteriorate over time. Depending on the thickness and quality of the anodization, the surface should last 10-20 years.

Order Process of Aluminum Profiles For Window and Door System

CHAL is specialized in manufacturing and supplying aluminum profiles for window and door systems all over the world. CHAL has a professional engineering team to design custom parts to meet the different requirements of the customers with ODM/OEM service, the most reasonable price & fast delivery guaranteed.

F&Q

Q1: Are you a trading company or manufacturer?

A1: We are a manufacturer.

Q2: What’s your price?

A2: Price depends on the buyer’s specific requirements.

1) Shop drawing/window schedule to show the window opening way, dimensions, quantity

2) Aluminum color

3) Type of glass