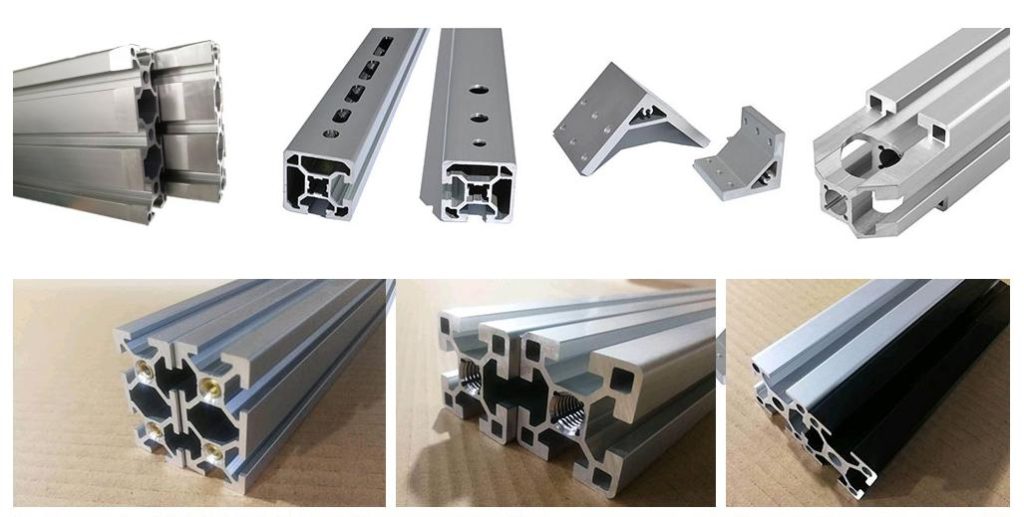

V-slot and T-slot are two types of aluminum extrusions that are commonly used in industrial, commercial, and even DIY projects. Both types of extrusions have a similar shape, but there are some key differences that make them better suited for different applications.

What is T Slot and V Slot Aluminum Profiles

- T-slot aluminum extrusions

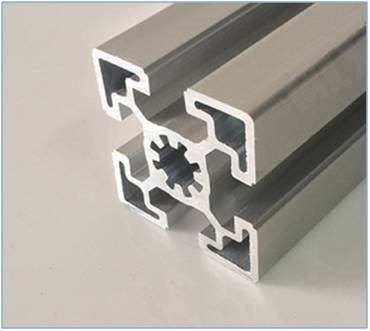

T-slot aluminum extrusions have a T-shaped cross-section, with a slot that runs along the entire length of the extrusion. This slot is designed to hold various types of T-slot connectors and accessories, which can be easily inserted and adjusted to create custom structures. T-slot extrusions are ideal for building structures that require a high degree of precision and modularity, such as industrial machinery, robotics, and custom workstations.

- V-slot aluminum extrusions

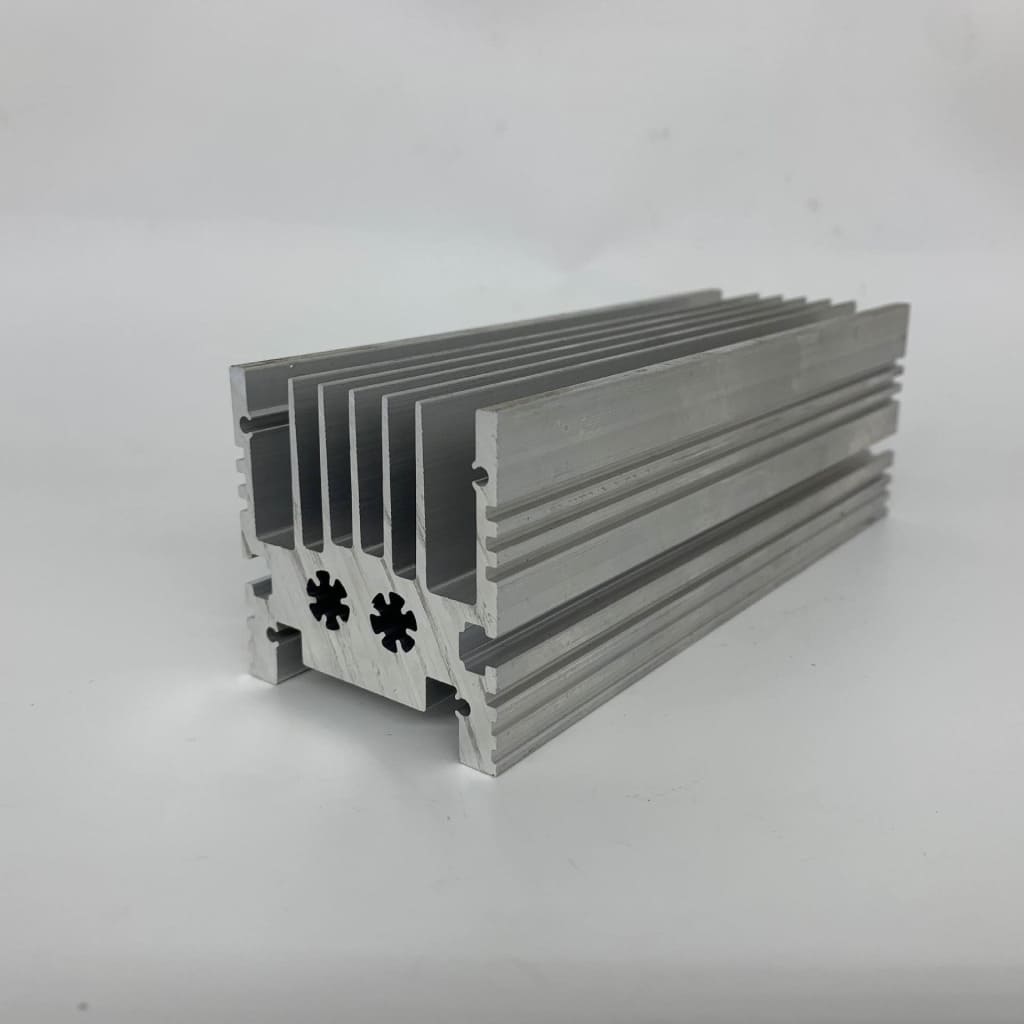

V-slot aluminum extrusions, on the other hand, have a V-shaped groove that runs along the entire length of the extrusion. This groove is designed to hold V-slot wheels, which can be used to create linear motion systems for 3D printers, CNC machines, and other types of equipment. V-slot extrusions are ideal for building structures that require precise linear motion and positioning, as they provide a smooth and stable platform for moving parts.

Comparison of V Slot vs T Slot

- Differences in design and construction

The primary difference in design and construction between V-slot and T-slot extrusions is the shape of their cross-section. V-slot extrusions have a V-shaped groove, while T-slot extrusions have a T-shaped slot. This difference in design affects the way that components and accessories can be attached to the extrusion, as well as the way that they can be joined together to form structures.

- Strength and durability

Both V-slot and T-slot extrusions are made from high-quality aluminum alloy, which provides strength, durability, and resistance to corrosion. However, the strength and durability of the extrusion can be influenced by factors such as the thickness of the walls, the type of alloy used, and the quality of the manufacturing process.

- Ease of assembly and customization

- slot extrusions are generally easier to assemble and customize, as the T-shaped slot allows for a wide range of connectors and accessories to be easily attached and adjusted. V-slot extrusions are more specialized and may require more precise positioning of components, which can make them more difficult to assemble and customize.

- Compatibility with accessories and components

- slot extrusions are generally more compatible with a wider range of accessories and components, as the T-shaped slot allows for greater flexibility and adjustability. V-slot extrusions are more limited in their compatibility, as they are designed specifically for use with V-slot wheels and linear motion systems.

- Cost

The cost of V-slot and T-slot extrusions can vary depending on factors such as the thickness of the walls, the type of alloy used, and the quality of the manufacturing process. In general, T-slot extrusions tend to be slightly more expensive than V-slot extrusions, as they are more versatile and can be used for a wider range of applications.

Overall, the choice between V-slot and T-slot extrusions depends on the specific needs of your project. While V-slot extrusions are better suited for linear motion systems and other applications that require precise movement, T-slot extrusions are more versatile and can be used to build a wider range of structures. By considering the differences in design, strength and durability, ease of assembly and customization, compatibility with accessories and components, and cost, you can choose the extrusion that is best suited for your project and achieve the desired results.

In conclusion, both T-slot and V-slot aluminum extrusions have unique features and advantages so that the right type of aluminum extrusion depends on the specific needs and requirements of the project. By understanding the differences and benefits of T-slot and V-slot aluminum, designers and engineers can select the most suitable extrusion to achieve their desired results.

Related Products

Related Articles